Active array base plate

An active array and substrate technology, applied in optics, instruments, electrical components, etc., can solve problems such as copper wire erosion, copper residual edge angle, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

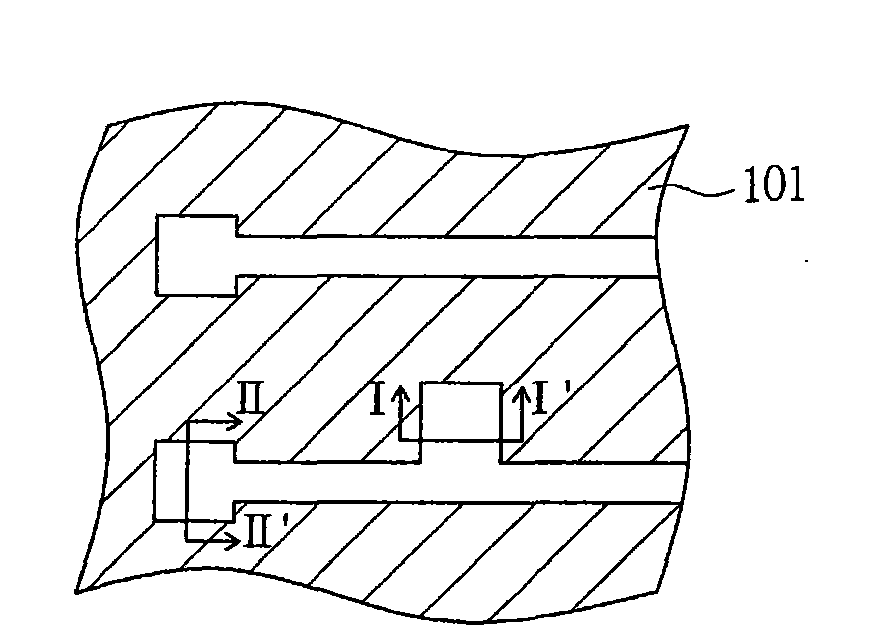

[0065] 1A, 2A, 3A, 4A, 5A, 6A, 7A, 8A, 9A, 10A, and 11A are the top views corresponding to the steps of the manufacturing method of the active array substrate according to an embodiment of the present invention. For the convenience of explanation and understanding, the top views are selectively displayed in perspective.

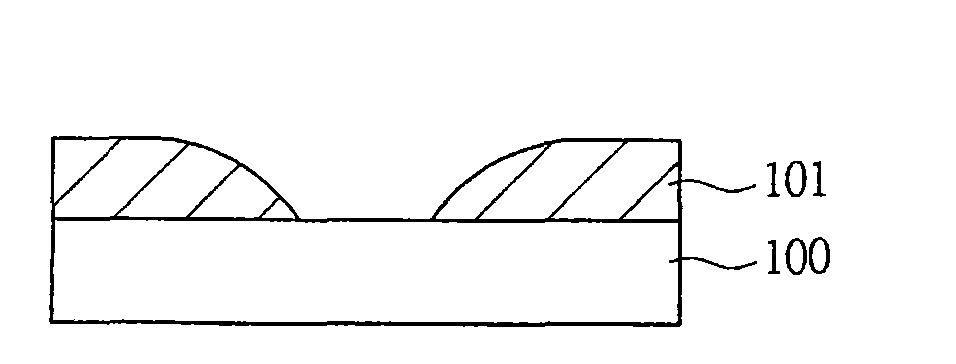

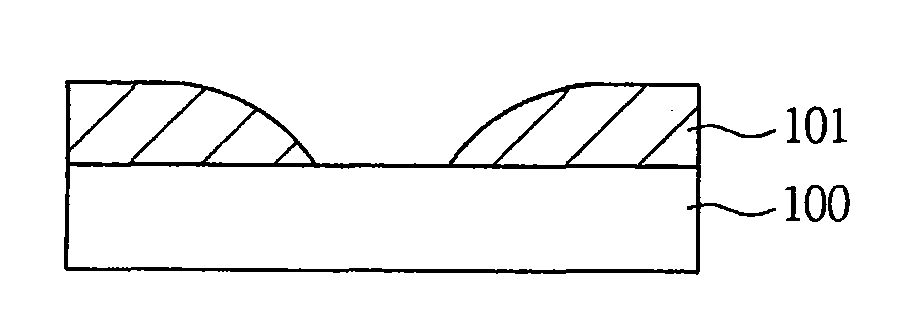

[0066] Please refer to Figure 1A to Figure 1C . Figure 1B and 1C respectively Figure 1A Sectional views along section lines I-I' and II-II'. It should be noted that the position corresponding to the section line I-I' is where the thin film transistors of the active array substrate are manufactured. Such as Figure 1B and 1C As shown in the figure, first, a substrate 100 is provided, and then a patterned photoresist layer 101 is formed on the substrate 100 .

[0067] Please refer to Figure 2A to Figure 2C . Figure 2B and 2C respectively Figure 2A Sectional views along section lines I-I' and II-II'. Using the patterned photoresist layer 101 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com