Photoelectric element

A technology of photoelectric components and light-emitting layers, applied in electrical components, circuits, optics, etc., can solve problems such as difficulty in improving the luminous efficiency of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

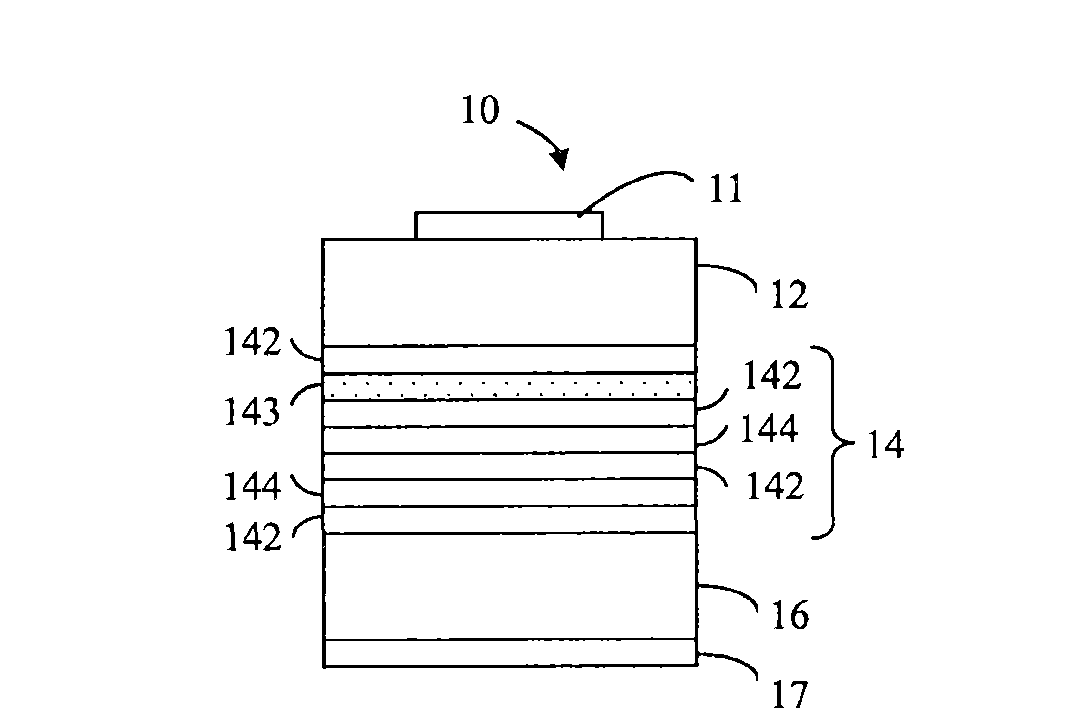

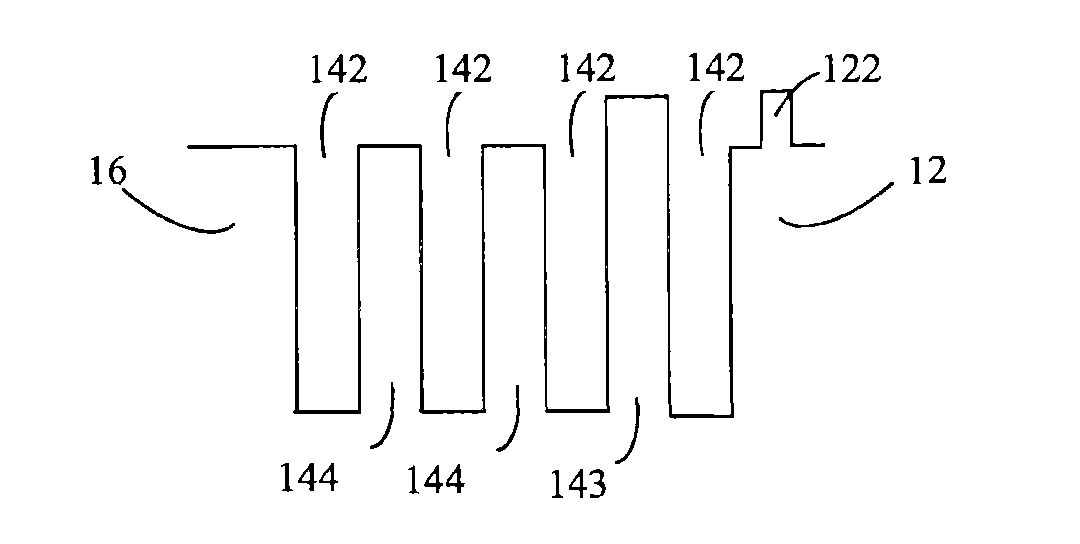

[0035] figure 1 Shown is the first embodiment of the present invention, a photoelectric element structure with multiple quantum well light-emitting layers. The photoelectric element 10 is a light-emitting diode structure, which includes a p-type cladding layer 12, an n-type cladding layer 16, a light-emitting layer 14 located between the p-type cladding layer 12 and the n-type cladding layer 16, and a second layer above the p-type cladding layer 12. A contact electrode 11 and a second contact electrode 17 in contact with the n-type cladding layer 16 . Wherein the light-emitting layer 14 is a multiple quantum well structure formed by stacking multiple well layers 142 and multiple barrier layers 144 alternately, and in the barrier layer in the light-emitting layer 14 closest to the p-type cladding layer 12, doping can change The impurity of the barrier is used to form the barrier modulation layer 143 . When a driving current is applied to the two contact electrodes 11 and 17 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com