Rotary combined machine tool for processing oversized pitch plane

A combined machine tool and ultra-large section technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, milling machine equipment, etc., can solve problems such as inability to process, insufficient smoothness of the plane, and inability to complete rotation, etc., to improve processing power, improve smoothness, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

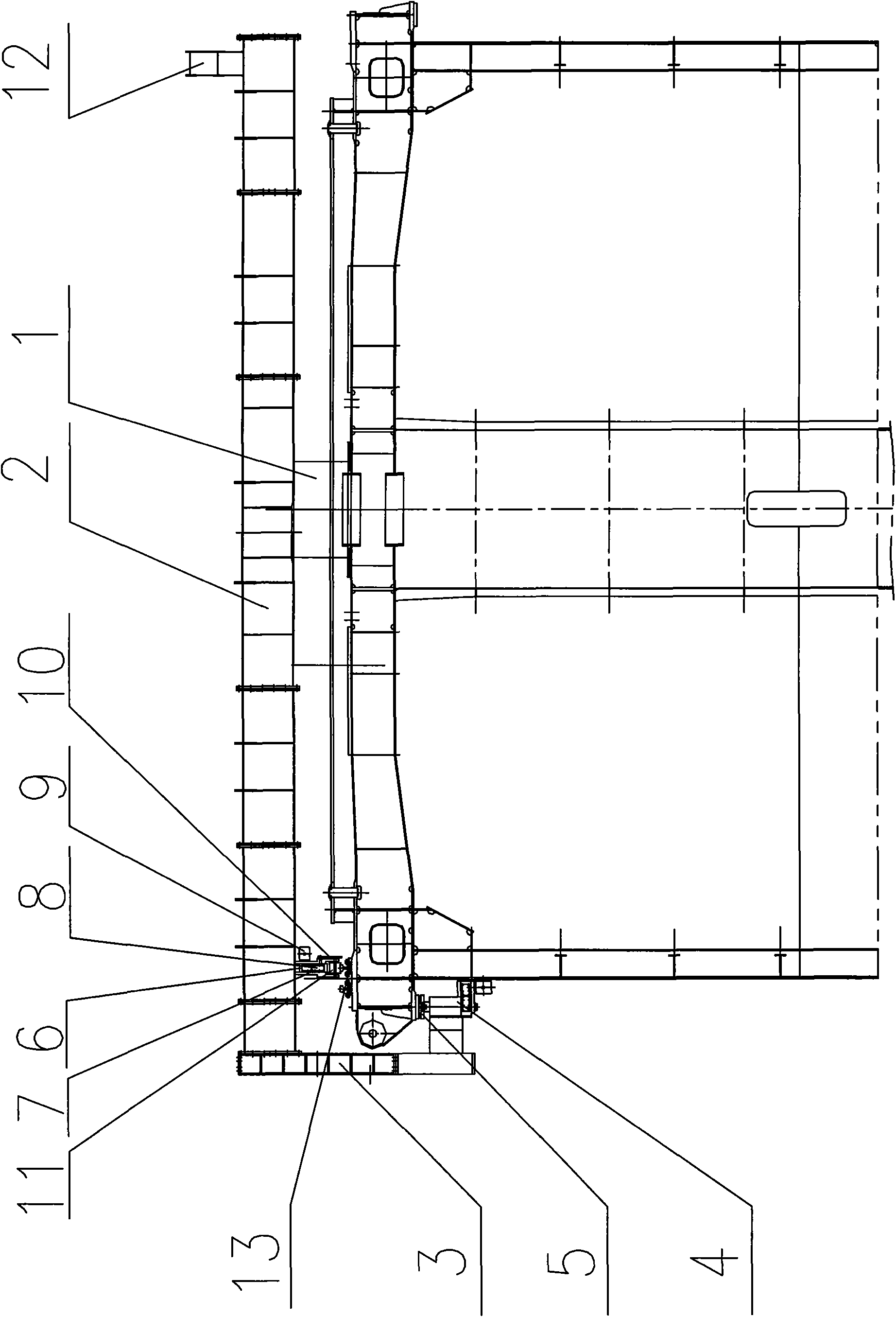

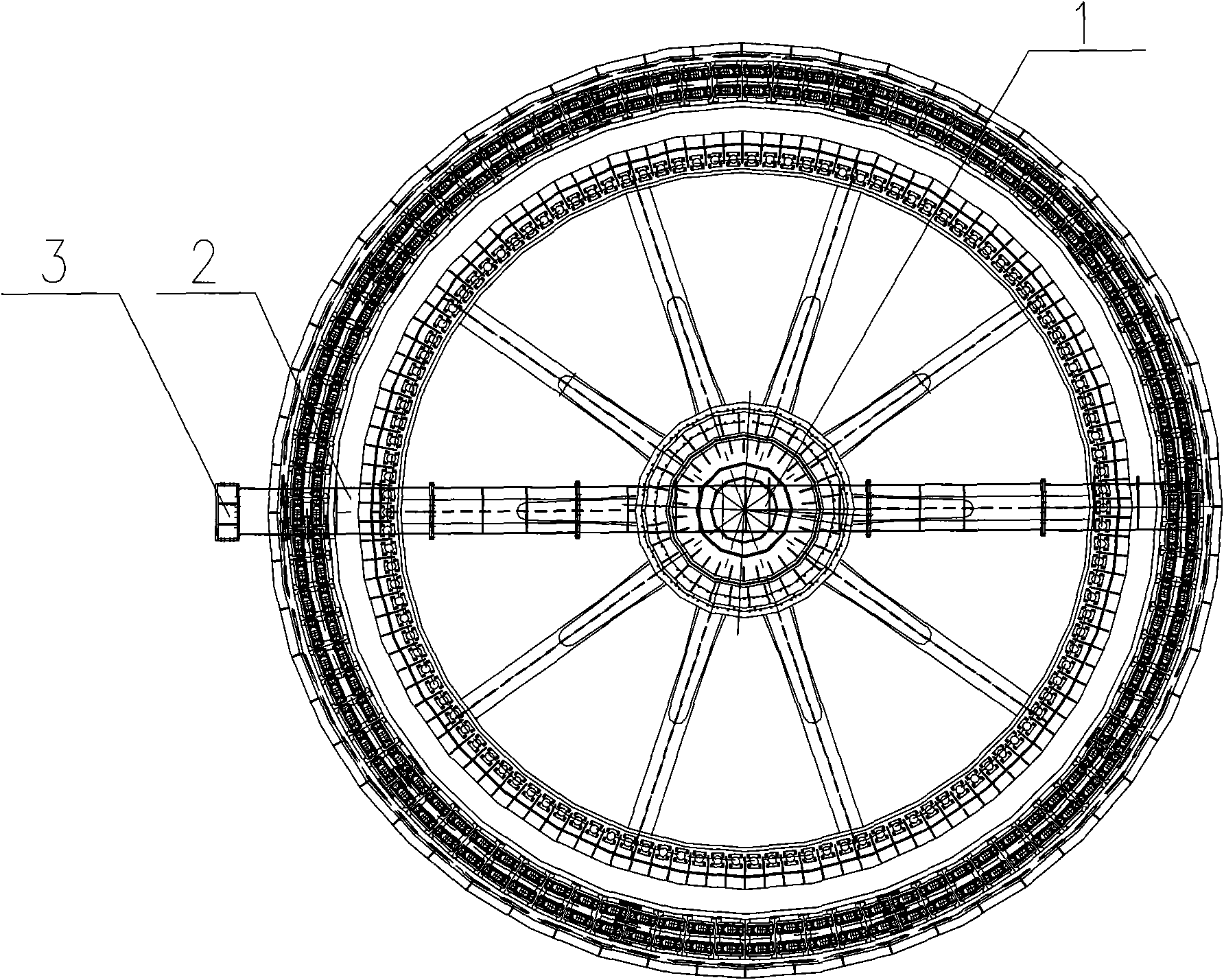

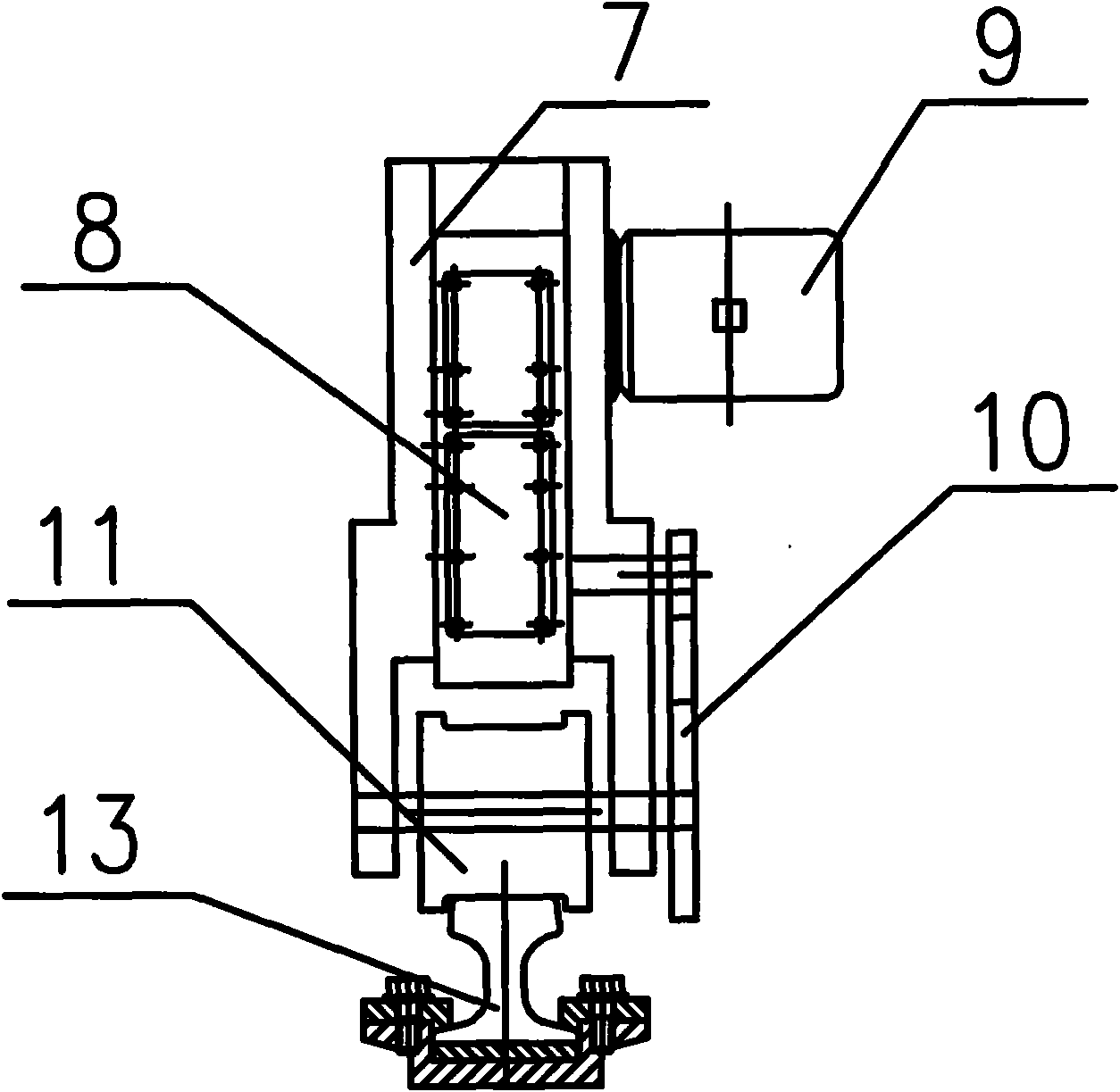

[0012] like figure 1 and figure 2 An embodiment of the rotary combined machine tool for processing super-large pitch circle planes according to the present invention is shown. The rotary combined machine tool includes a rotary machine tool 1, a horizontal beam 2, and a vertical beam 3. The rotary machine tool 1 is refitted from a super-large rotary bearing. It is installed in the matching drum, but the rotary machine tool 1 does not rotate actively, but passively rotates around the center of the pitch circle, and the speed is controlled by the feeding device 6; It has enough rigidity and strength to prevent unnecessary vibration. The length of the horizontal beam 2 can be adjusted according to the size of the pitch circle to be processed. The center of the horizontal beam 2 is disposed on the rotary machine tool 1. There is a vertical beam 3, and a power head 4 is arranged at the other end of the vertical beam. The power of the power head 4 is 11KW, and a cutter head 5 is ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap