Extruded acryl composite foam board and preparation method thereof

An acrylic and composite technology, applied in chemical instruments and methods, synthetic resin layered products, decorative arts, etc., can solve the problems of low production efficiency, single variety, insufficient surface hardness and smoothness, and improve production efficiency , the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] step 1:

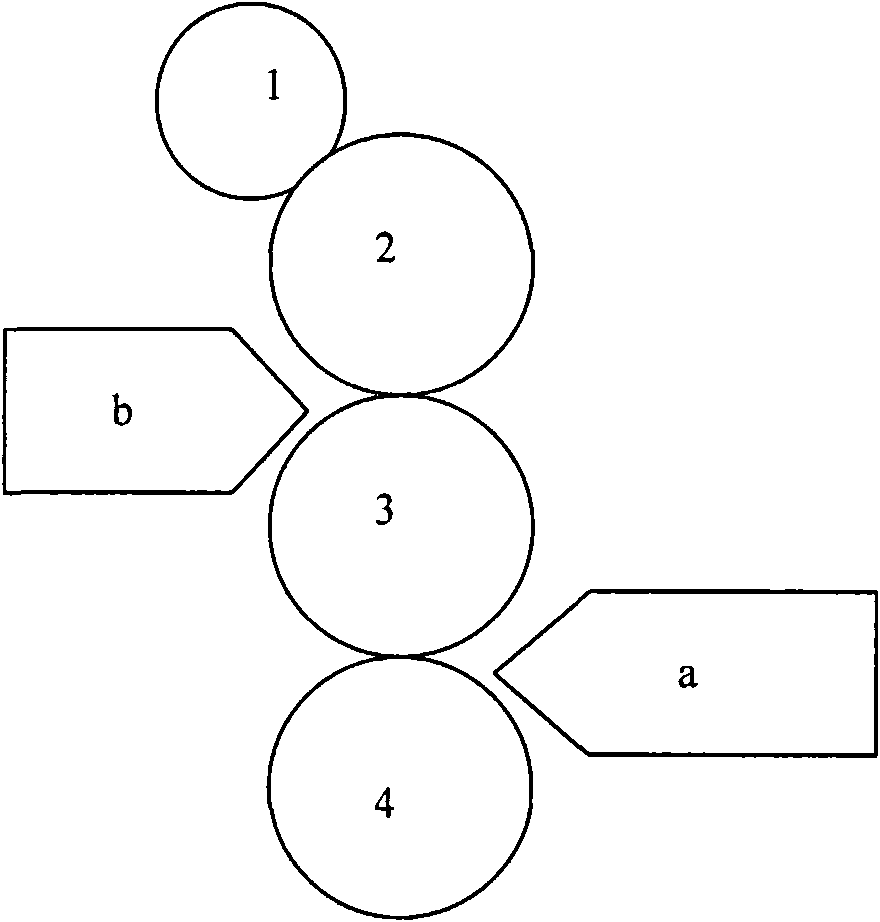

[0035] First, mix the raw materials of each layer of the board above evenly in their respective mixing hoppers, and at the same time, carry out drying treatment at 80°C for 5 hours, and set the temperature of one of the extruders in the range of 200-250°C. The mixture of 96.9% PMMA, 3% titanium dioxide color masterbatch, and 0.1% benzotriazole UV absorber is melted and plasticized and then extruded to the distributor as the second layer of the plate, and the second extruder The temperature of the fuselage is set at 200-260°C. The mixture of 64% ABS, 30% PMMA and 6% titanium dioxide masterbatch is melted and plasticized, and then extruded into the distributor as the third layer of the board. The temperature of the body of the third extruder is set at 200-250°C, and the mixture of 0.2% benzotriazole UV absorber and 99.8% PMMA is melted and plasticized and extruded to the distributor as a plate fourth floor;

[0036] Step 2:

[0037] After extruding the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com