Reaction unit for sludge acclimation and polyhydroxyalkanoates synthesis by sludge and synthetic method thereof

A technology of polyhydroxyalkanoate and synthesis reaction, which is applied in the field of biodegradable material polyhydroxyalkanoate synthesis, can solve the problems that the yield and accumulation time of polyhydroxyalkanoate cannot meet the requirements of industrialization, and achieve structural The effect of simplicity, simple conditions, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

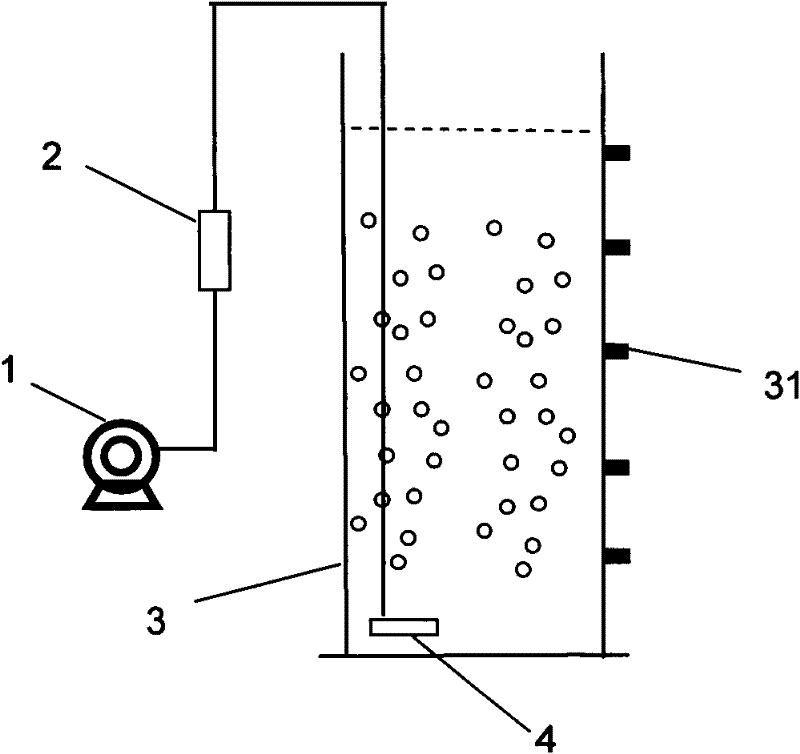

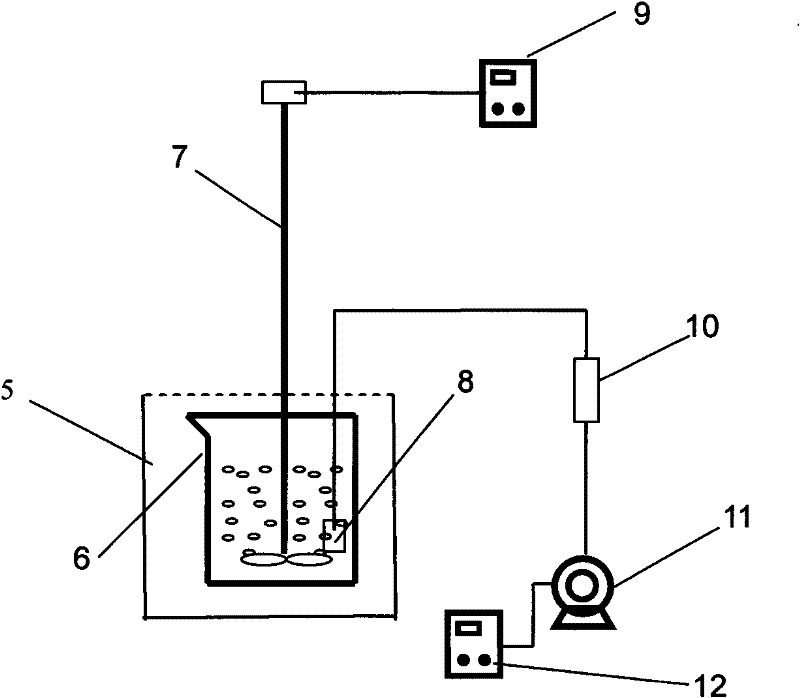

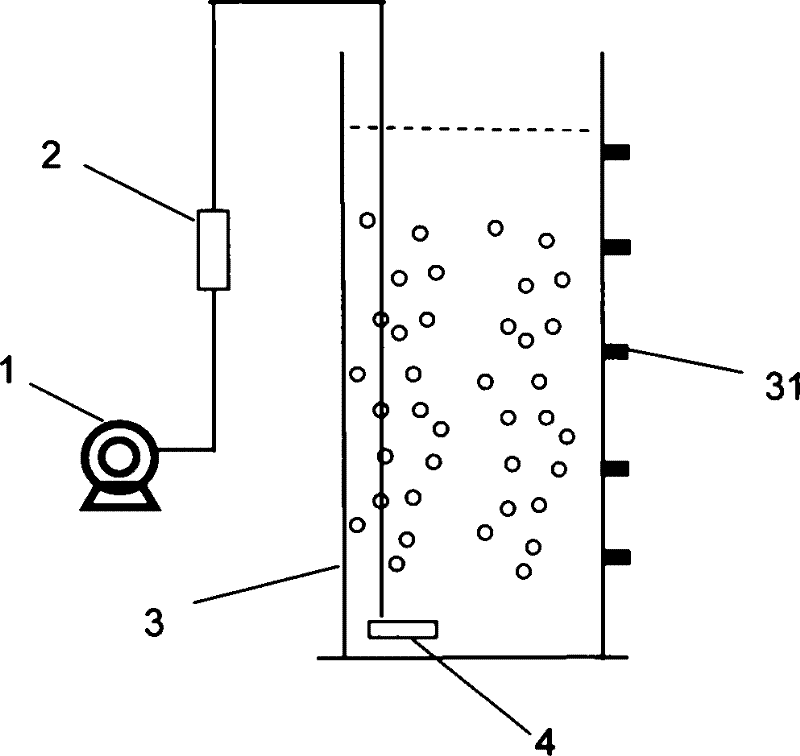

[0019] The reaction device for domesticating sludge and synthesizing polyhydroxyalkanoate from sludge in the present invention includes a sludge domesticating device and a synthesis reactor.

[0020] The sludge domestication device is provided with a domestication reaction tank 3 and a domestication reaction aeration head 4, and the domestication reaction aeration head 4 is placed at the bottom of the domestication reaction tank 3, and the air inlet of the domestication reaction aeration head 4 is connected to the device through a connecting pipe. It is connected to the rotameter 2 and the air compressor 1 outside the domestication reaction tank 3, the aeration rate of the domestication reaction aeration head 4 is controlled by the rotameter 2, the total volume of the domestication reaction tank 3 is 6L, and the domestication reaction aeration head 4. Sand core aeration heads are used, and a mud discharge port 31 with a valve is provided at every 1L of the tank wall of the dome...

Embodiment 2~7

[0025] The sludge synthesis of PHAs was carried out by changing different acetic acid dosages and different pH values. Other methods and conditions were the same as in Example 1. The results of sludge accumulation of PHAs are shown in Table 1.

[0026] Table 1 Comparison of main parameters of sludge accumulated PHAs under different carbon source dosage and pH value

[0027]

[0028] By embodiment 1 method, get 5L MLSS and be the activated sludge of 1g / L, add with CH 3 COOH 0.4mL / L, KCl117mg / L, K 2 HPO 4 ·3H 2 O 75mg / L, NH 4 Cl 97mg / L, MgSO 4 75mg / L, CaCl 2 27mg / L, FeCl 3 ·6H 2 05mg / L, peptone 167mg / L, and yeast extract 62mg / L, adjust the pH value to 7.0, and the aeration rate is 1L / L / min. After 19 hours of aeration, stop the aeration, and open the mud discharge port to discharge Sludge, control the sludge concentration in the acclimation reaction tank to 1g / L, discharge 3L supernatant after sedimentation for 20min, and a cycle is 20h; then "water intake - ae...

Embodiment 8

[0031] By embodiment 1 method, get 5L MLSS and be the domestication reaction tank that the activated sludge of 2g / L drops into the sludge domestication device, add with CH 3 COOH 0.75mL / L, KCl 234mg / L, K 2 HPO 4 ·3H 2 O 150mg / L, NH 4 Cl 194mg / L, MgSO 4 150mg / L, CaCl 2 54mg / L, FeCl 3 ·6H 2 O 10mg / L, peptone 334mg / L, yeast extract 124mg / L prepared medium, adjust the pH value to 9.0, control the aeration rate by rotameter to 2L / L / min, after aerobic aeration for 23h, stop Aerate, open the sludge outlet to discharge sludge, control the sludge concentration in the domestication reaction tank to 2g / L, discharge 3L supernatant after 30min of sedimentation, and a cycle is 24h; then "water intake - aerobic aeration - sludge discharge - After 10 cycles of "sedimentation-effluent" culture and domestication, the sludge properties were stable, the appearance gradually changed from black to light brown, and the sludge volume index (SVI) was 102mL / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com