Aspheric optical element surface shape detection device

A technology for detecting optical components and surface shape, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of computational hologram processing, assembly and adjustment difficulties, etc., to shorten the detection cycle, reduce the deviation, and reduce the detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

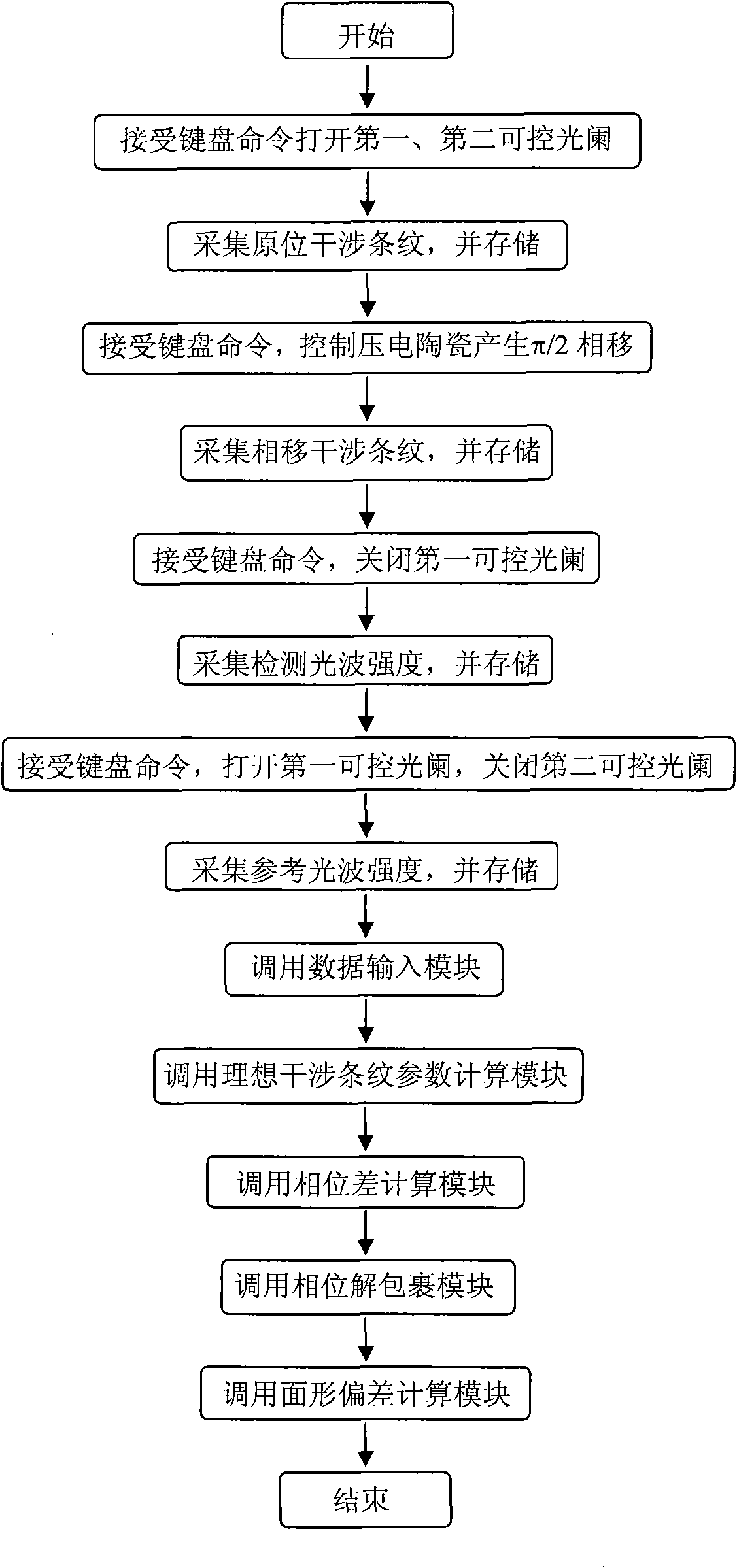

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

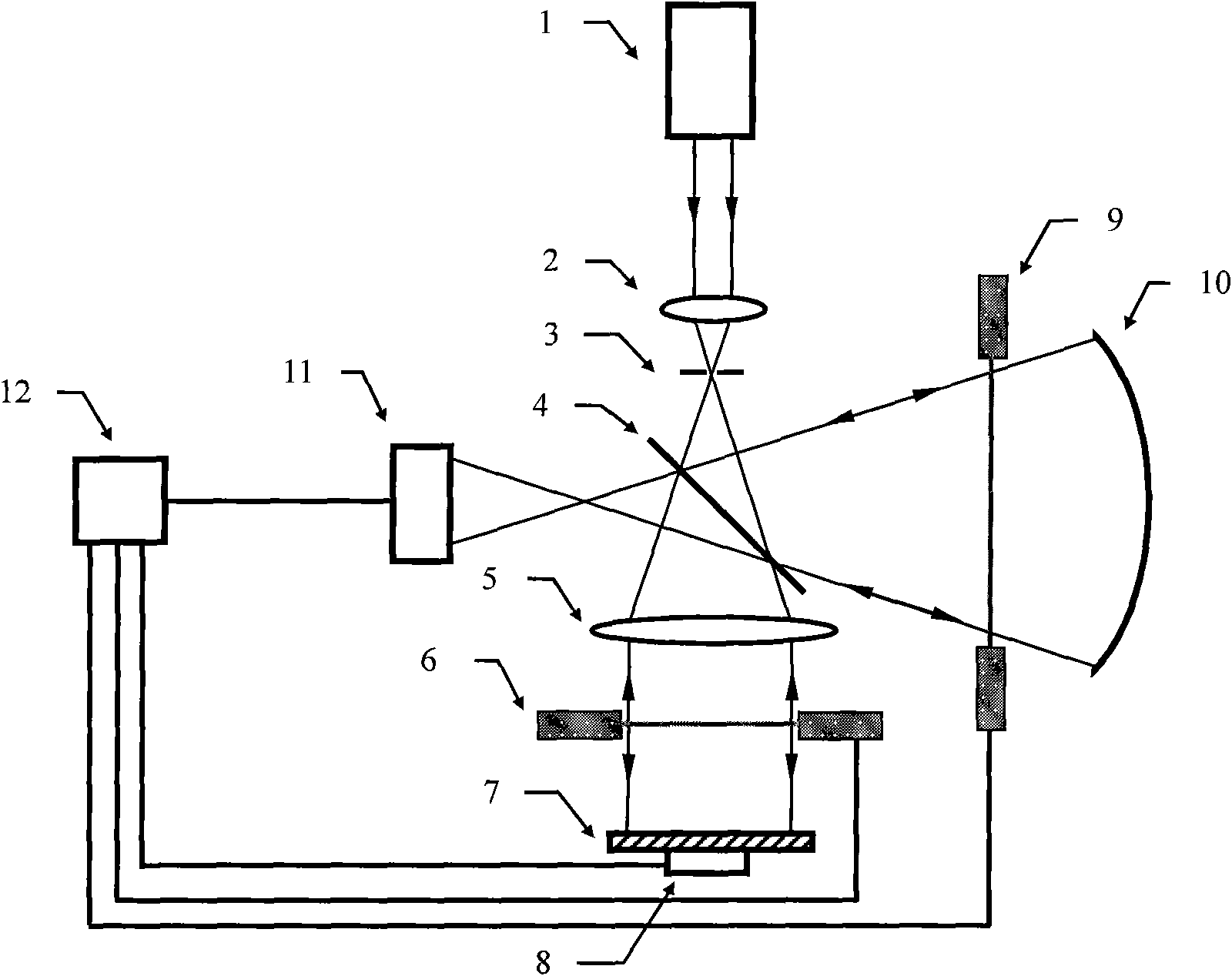

[0014] according to figure 1 As shown, the aspherical optical element surface shape detection device of the present invention includes a helium-neon laser 1, a microscope objective lens 2, a pinhole filter 3, a beam splitter 4, an aplanatic lens 5, a first controllable diaphragm 6, a standard plane Mirror 7, piezoelectric ceramics 8, second controllable aperture 9, CCD detector 11, computer 12. The operating wavelength of the helium-neon laser 1 is 632.8nm, the magnification of the microscope objective lens 2 is 100, the diameter of the pinhole filter 3 is 5 μm, and the beam splitter 4 is a semi-transparent and half-reflective 45° right-angle prism, and the splitting ratio of the splitting surface is is 1:1, the surface shape accuracy of the standard plane mirror 7 is better than λ / 20 and placed on the piezoelectric ceramic 8, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com