Mass-sensitive chemical sensor

A mass-sensitive, chemical-sensing technology, applied in the field of mass-sensitive chemical sensors, which can solve the problems of contamination-sensitive surfaces, sensor inability, removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

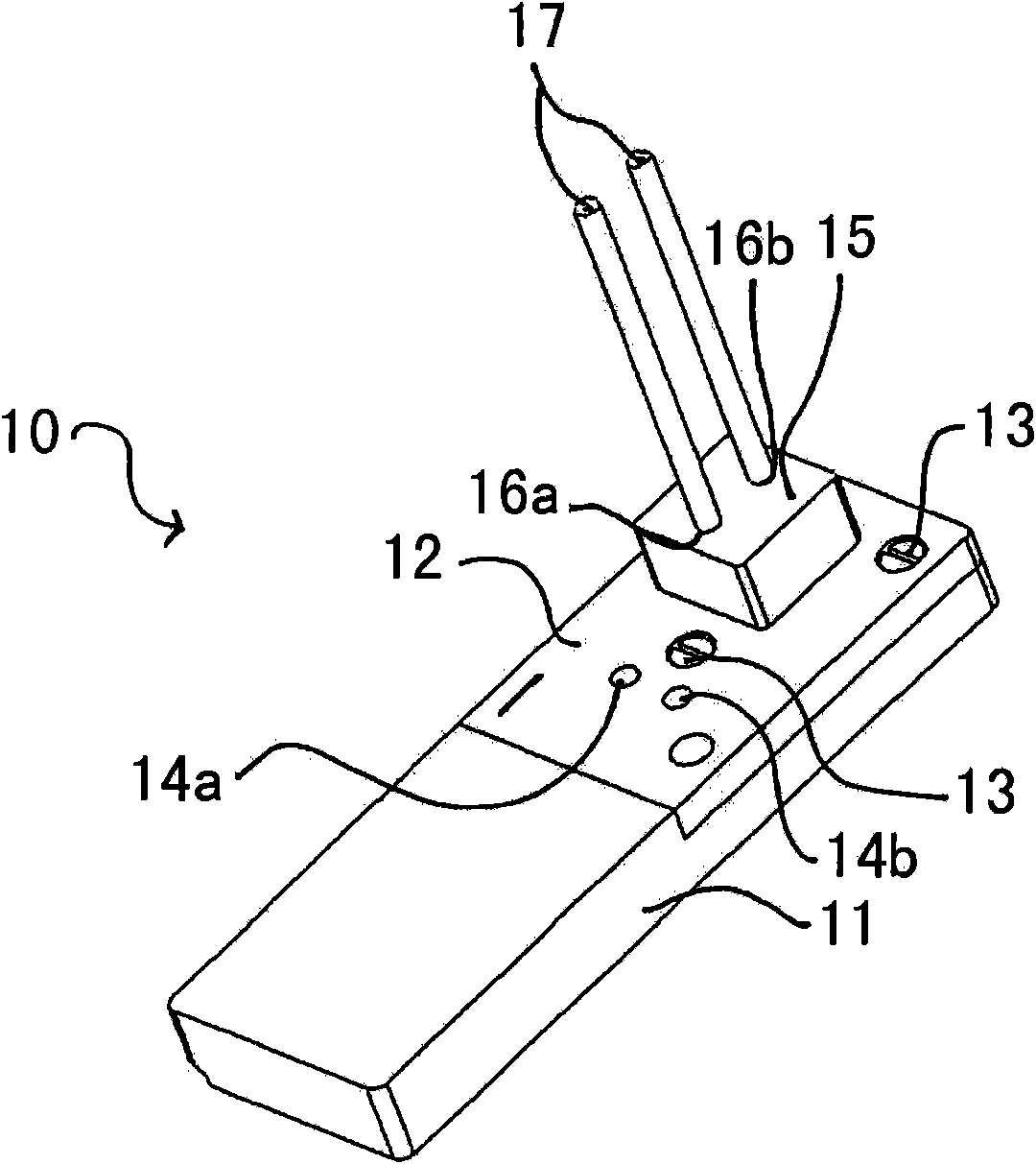

[0095] first reference figure 1 , the sensing element denoted by 10 includes a base part 11 and a cover part 12 connected to the base part 11 by screws 13 . Both the cover part and the base part are formed from the substantially rigid plastic material acetal. The cover part 12 has two holes 14a, 14b for connecting electrical contacts (eg plugs to wires) from a sensing instrument such as the Attana A100QCM instrument. The cover part 12 has connected thereto a rubber gasket 15 having two through holes 16a, 16b. Tubes 17 are connected to the holes 16a, 16b for passing sample fluids, buffers, etc. between the sensing elements and the instrument.

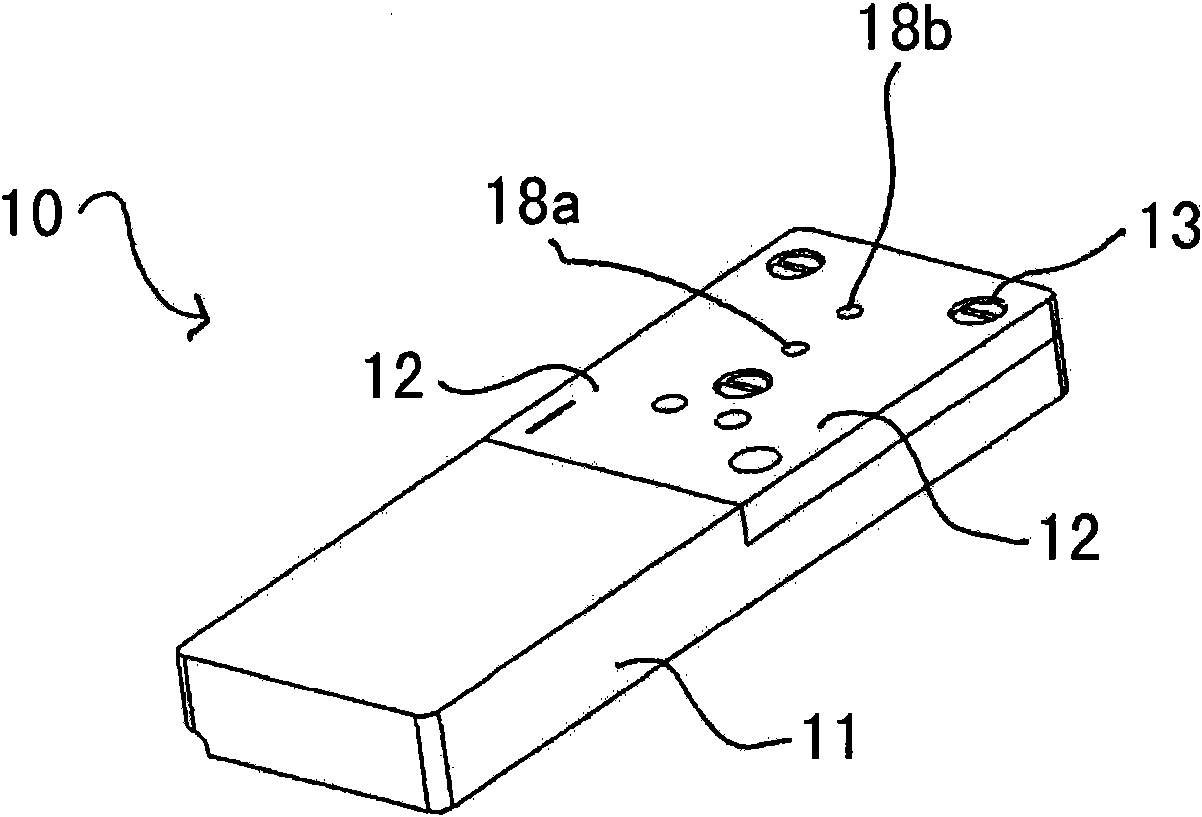

[0096] Remove gasket 15 ( figure 2 with Figure 4 ), it can be seen that the cover part comprises two holes 18a, 18b. The holes 18a, 18b are channels through which a sample fluid or the like can pass and flow into a sensor located in the sensing element, as will be described in detail below.

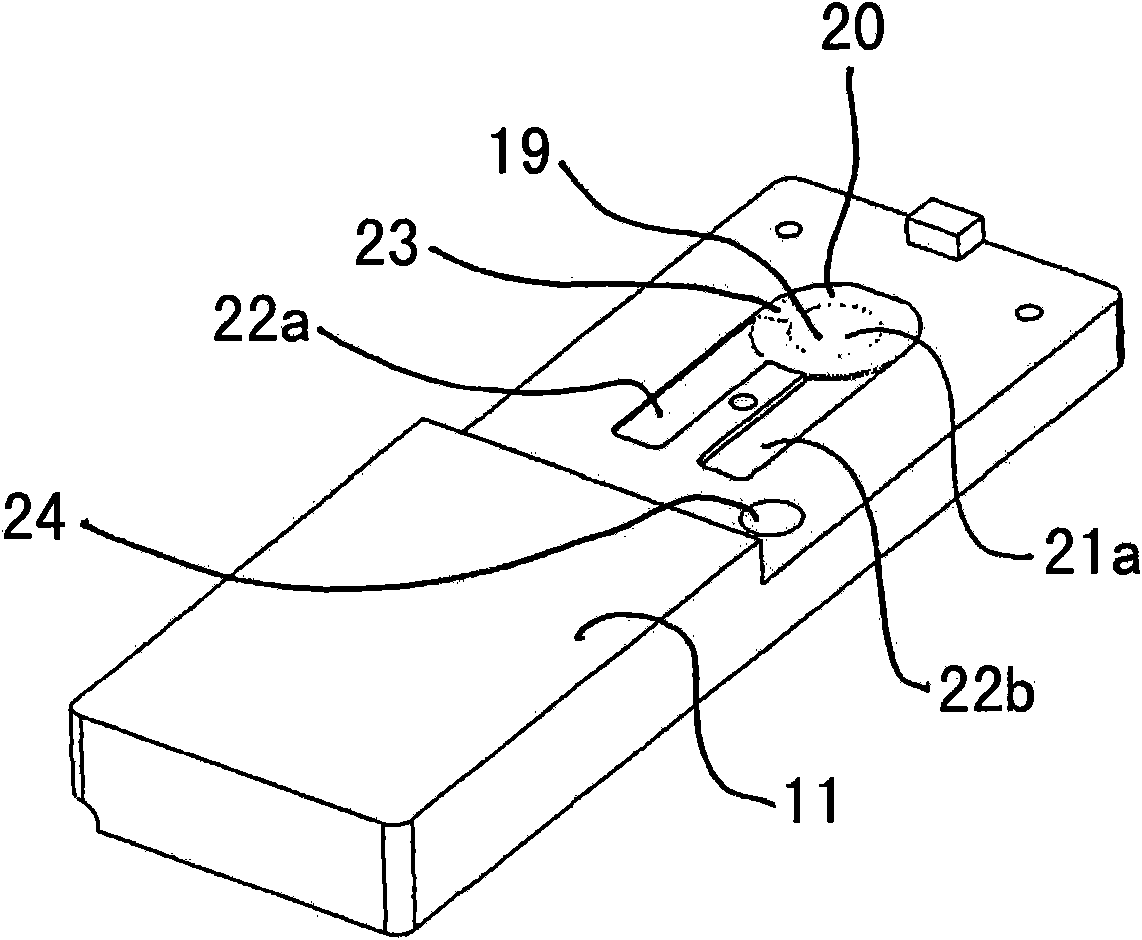

[0097] The QCM sensor 19 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com