Thermoplastic elastomers for injection bonding with polypropylene materials

A thermoplastic elastomer, polypropylene material technology, applied in the field of thermoplastics, can solve the problems of poor surface scratch resistance, poor blending effect, poor mechanical properties, etc., and achieve good scratch resistance, fine surface, and mechanical properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

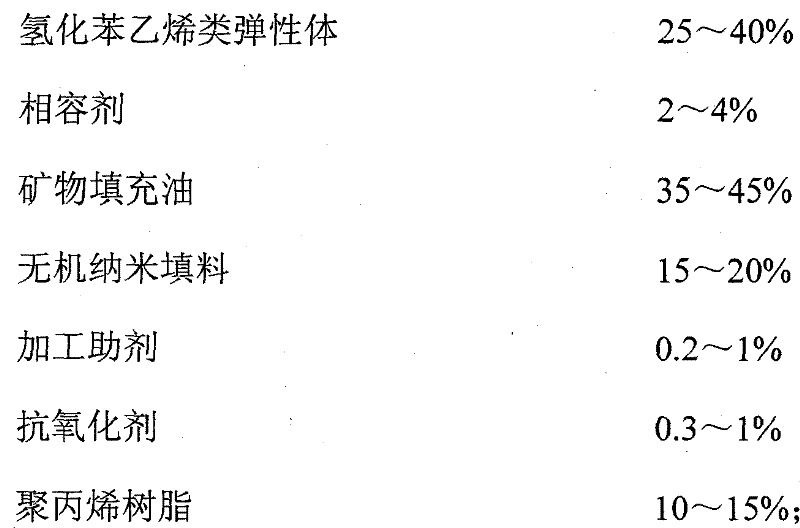

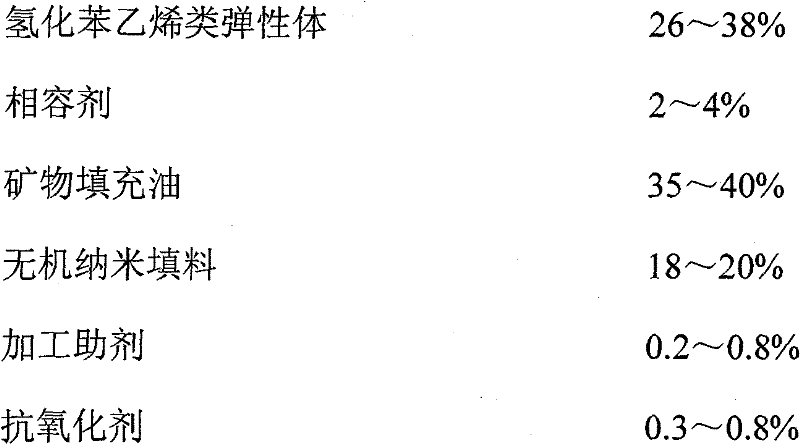

[0040] Thermoplastic elastomers for injection bonding with polypropylene materials, consisting of the following components in parts by weight,

[0041] SEBS G6933 27%

[0042] SEBS-g-MAH 3%

[0043] Paraffinic oil 38%

[0044] Talc 18%

[0045] Dimethicone 0.5%

[0046] Antioxidant 0.5%

[0047] 5090T homopolymer polypropylene resin 13%.

[0048] The paraffin-based paraffin oil has a flash point of 250° C. and a viscosity of 15 Cps at 25° C.

[0049] The mesh number of described talcum powder is 5000 mesh.

[0050] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a ratio of 1:2.

[0051] The preparation method of the present invention is as follows: firstly, weigh each component of the above-mentioned formula according to the ratio for use; secondly, fully mix SEBS G6933 and paraffin-based alkane oil with a high-speed mixer, so that the mineral oil is completely absorbed in hydrogenated styrene In the elastomer; third, add the remaining SEBS-g-MA...

Embodiment 2

[0053] Thermoplastic elastomers for injection bonding with polypropylene materials, in percentages by weight, comprising the following components,

[0054] SEBS G1651 28%

[0055] SEBS-g-MAH 2%

[0056] Paraffinic oil 37%

[0058] Polyethylene wax 1%

[0059] Antioxidant 0.4%

[0060] 5090T homopolymer polypropylene resin 13.6%.

[0061] The paraffin-based paraffin oil has a flash point of 245°C and a viscosity of 16 Cps at 25°C.

[0062] The barium sulfate mesh number is 5500 mesh.

[0063] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a ratio of 1:1.2.

[0064] The preparation method is the same as in Example 1 and will not be repeated here.

Embodiment 3

[0066] Thermoplastic elastomers for injection bonding with polypropylene materials, in percentages by weight, comprising the following components,

[0067] SEBS G6933 25%

[0068] SEBS4033 15%

[0069] SEBS-g-MAH 4%

[0070] Paraffinic oil 25%

[0072] Dimethicone 0.2%

[0073] Erucamide 0.5%

[0074] Antioxidant 0.5%

[0075] 5090T homopolymer polypropylene resin 14.8%.

[0076] The paraffin-based paraffin oil has a flash point of 300° C. and a viscosity of 17 Cps at 25° C.

[0077] The calcium carbonate mesh number is 6000 mesh.

[0078] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a ratio of 1:1.2.

[0079] The preparation method is the same as in Example 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com