Printed wiring board and method for manufacturing the same

A technology for printed wiring substrates and manufacturing methods, applied in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of signal frequency band degradation and signal frequency band degradation of printed wiring substrates, achieve characteristic impedance matching, and suppress characteristic impedance loss. The effect of matching and suppressing electromagnetic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

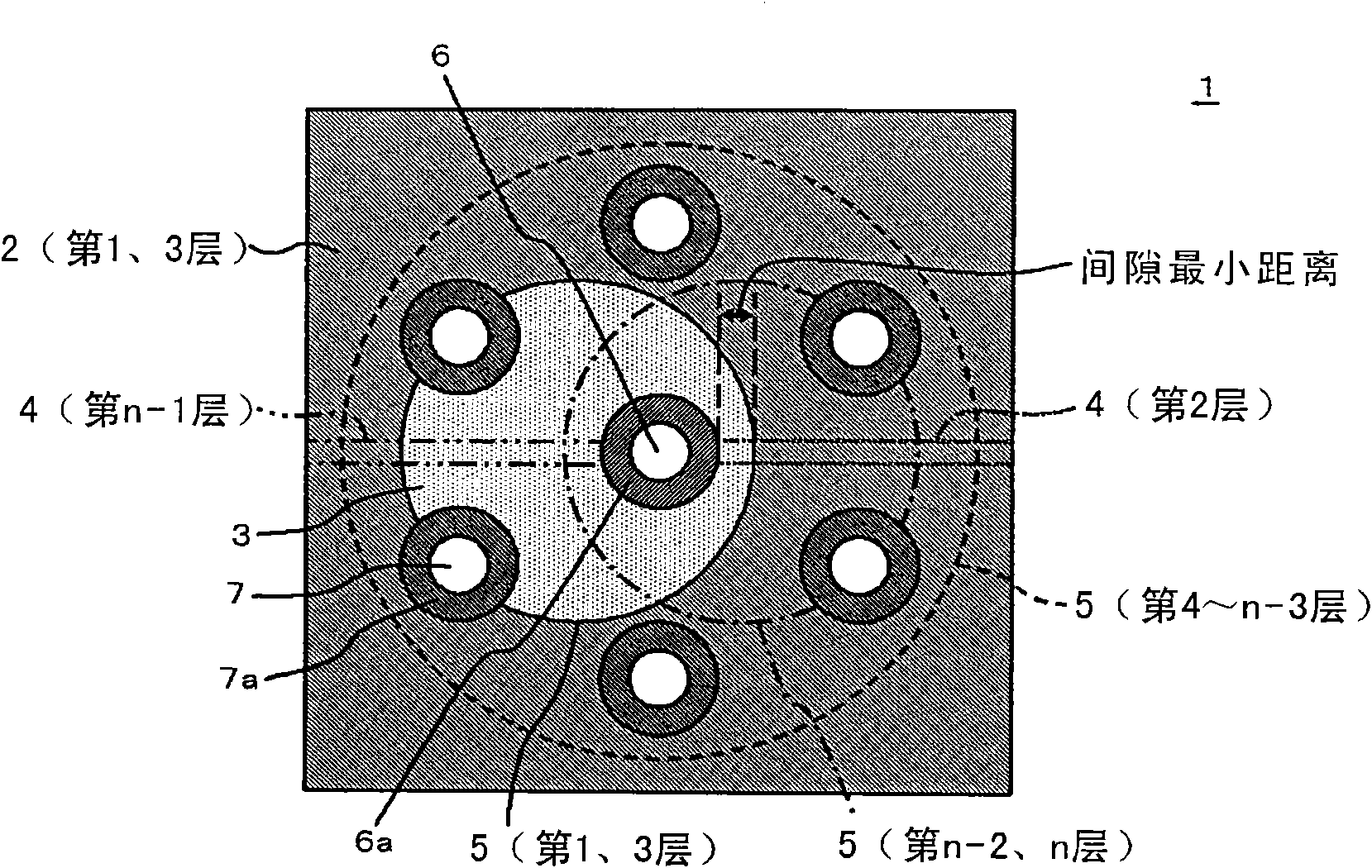

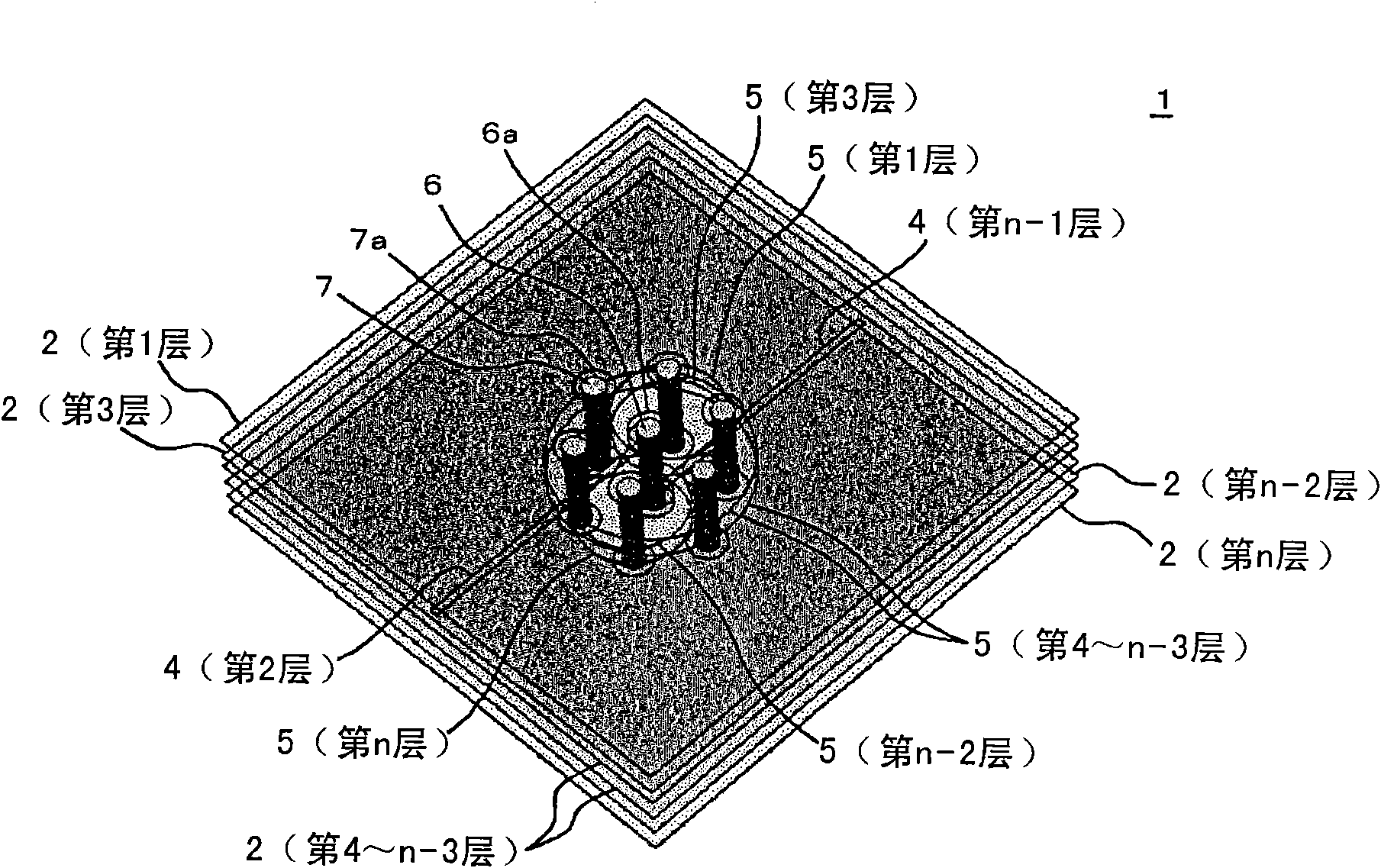

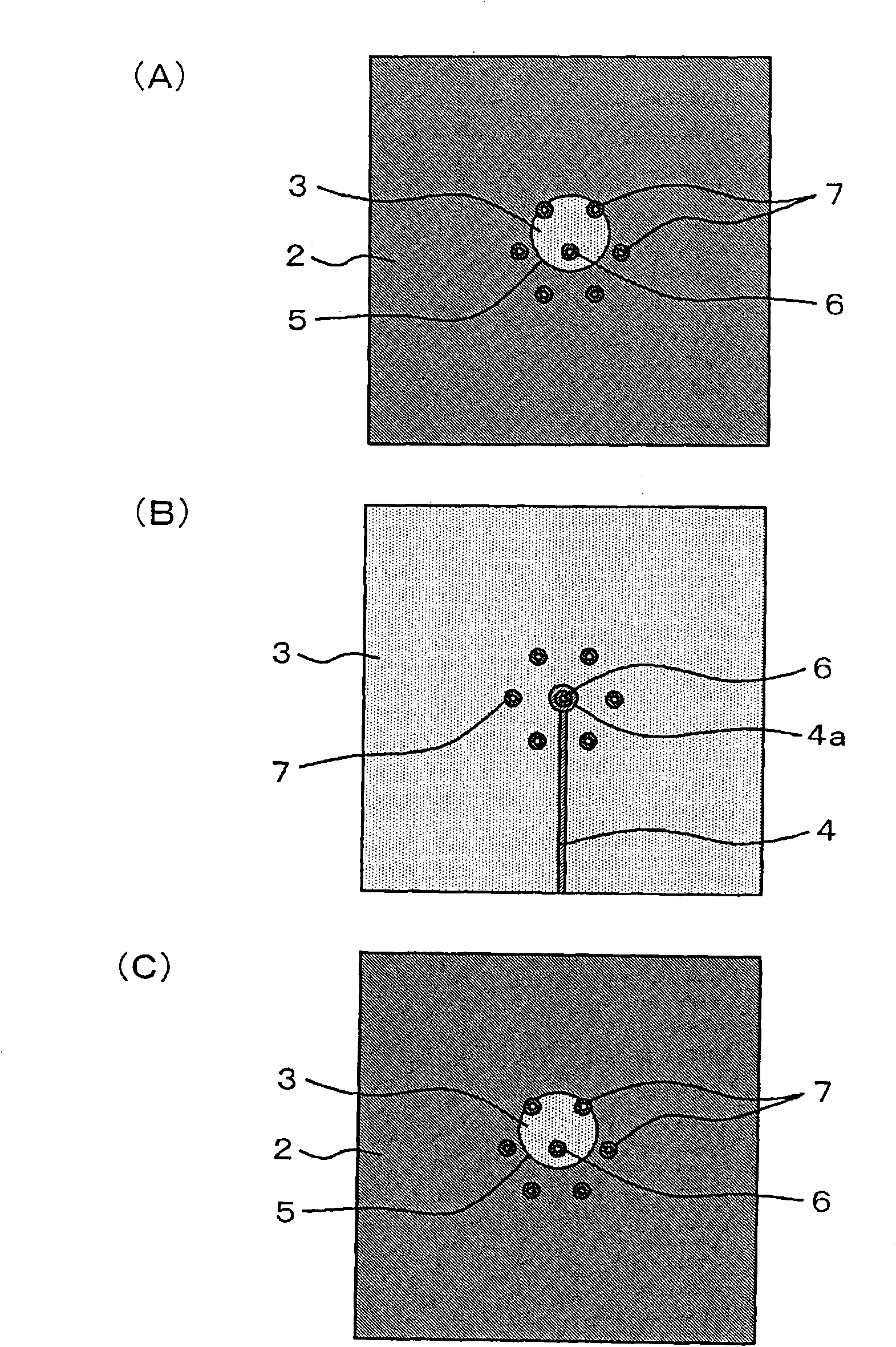

[0030] A printed wiring board according to Embodiment 1 of the present invention will be described with reference to the drawings. figure 1 It is a partial plan view viewed from the first layer side of the GND layer, and schematically shows the structure around the via holes of the printed wiring board according to Example 1 of the present invention. figure 2 It is a partial perspective view showing in outline the structure of the conductor portion around the via hole of the printed wiring board according to the first embodiment of the present invention. image 3 It is a cross-sectional view of (A) the GND layer above the signal wiring, (B) a cross-sectional view of the signal wiring layer, and (C) the signal wiring schematically showing the structure of the printed wiring board according to Embodiment 1 of the present invention. Cross-sectional view of the lower GND layer. Figure 4 It is a cross-sectional view schematically showing the structure of the printed wiring board...

Embodiment 2

[0071] Next, a printed wiring board according to Embodiment 2 of the present invention will be described with reference to the drawings. Figure 9 It is a partial plan view viewed from the first layer side of the GND layer, and schematically shows the structure around the via holes of the printed wiring board according to Example 2 of the present invention.

[0072] In the printed wiring board 1 of the second embodiment, the first-stage upper layer (first layer, n-2th layer) and the first-stage lower layer (the second layer, n-1th layer) of the layer (second layer, n-1th layer) of the signal wiring 4 are arranged The outer shape of the gap 5 of the GND layer 2 of the third layer and the nth layer) is formed as an ellipse (or an oblong shape) that is eccentric with respect to the axis of the via hole 6 for the signal in the following manner, that is, in the slave signal The distance between the signal via hole 6 and the gap 5 in the direction in which the signal wiring 4 is dra...

Embodiment 3

[0074] Next, a printed wiring board according to Embodiment 3 of the present invention will be described with reference to the drawings. Figure 10 It is a partial plan view viewed from the first layer side of the GND layer, and schematically shows the structure around the via holes of the printed wiring board according to Example 3 of the present invention.

[0075] In the printed wiring board 1 of Example 3, the first-stage upper layer (first layer, n-2th layer) and the first-stage lower layer (second layer, n-1th layer) of the layer (second layer, n-1th layer) of the signal wiring 4 are arranged The outer shape of the gap 5 of the GND layer 2 of the third layer and the nth layer) is formed as a quadrilateral (or a polygon) that is eccentric with respect to the center of the axis of the via hole 6 for the signal in the following manner, that is, when the via hole 6 for the slave signal The distance between the signal via hole 6 and the gap 5 in the direction in which the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com