Aluminum deoxidizing welding wire

A technology of welding wire and welding slag, which is applied in the field of welding wire to improve the characteristics of welding seams, and can solve the problems of infrequent use of gas and non-recommended use of gas by welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

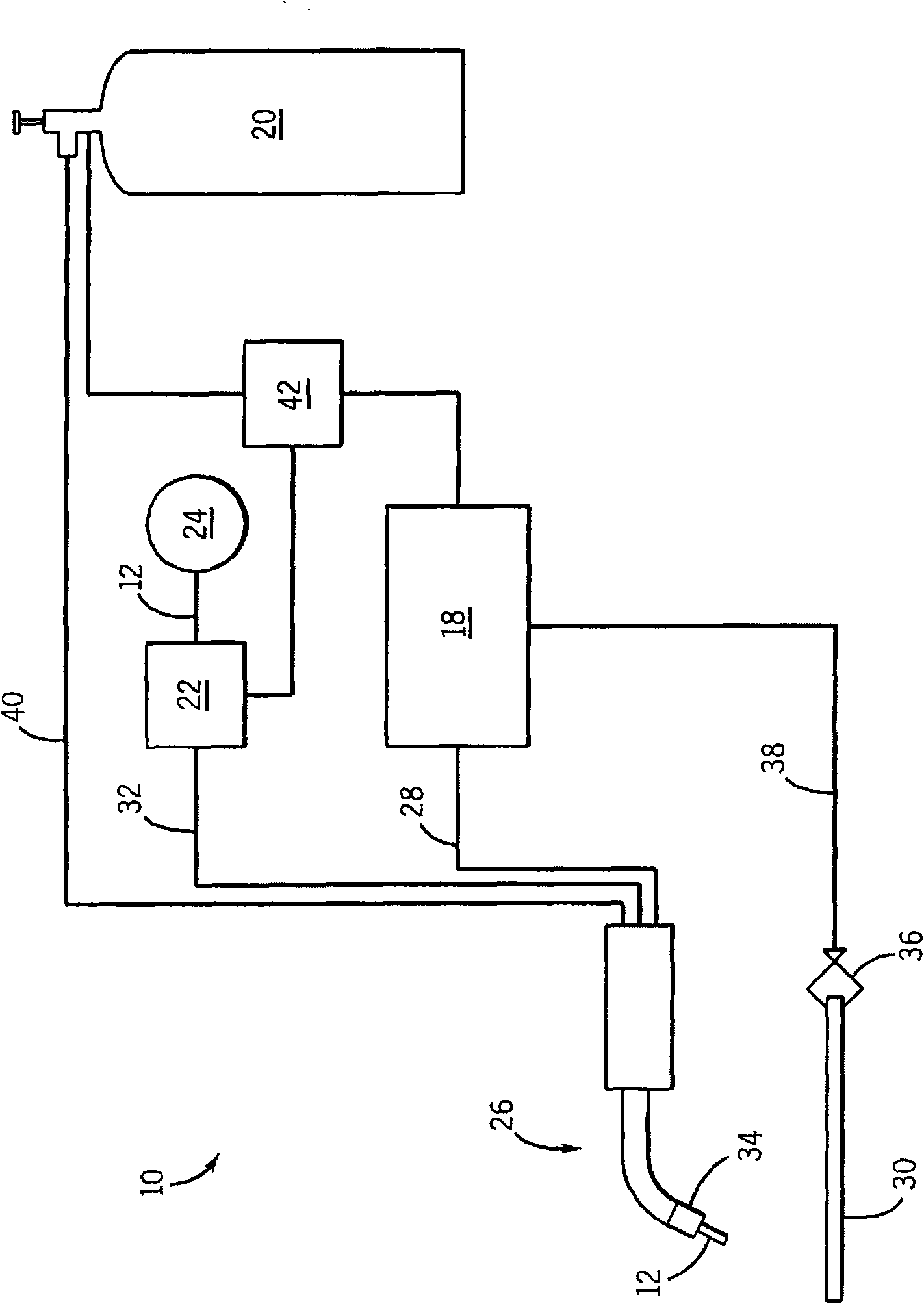

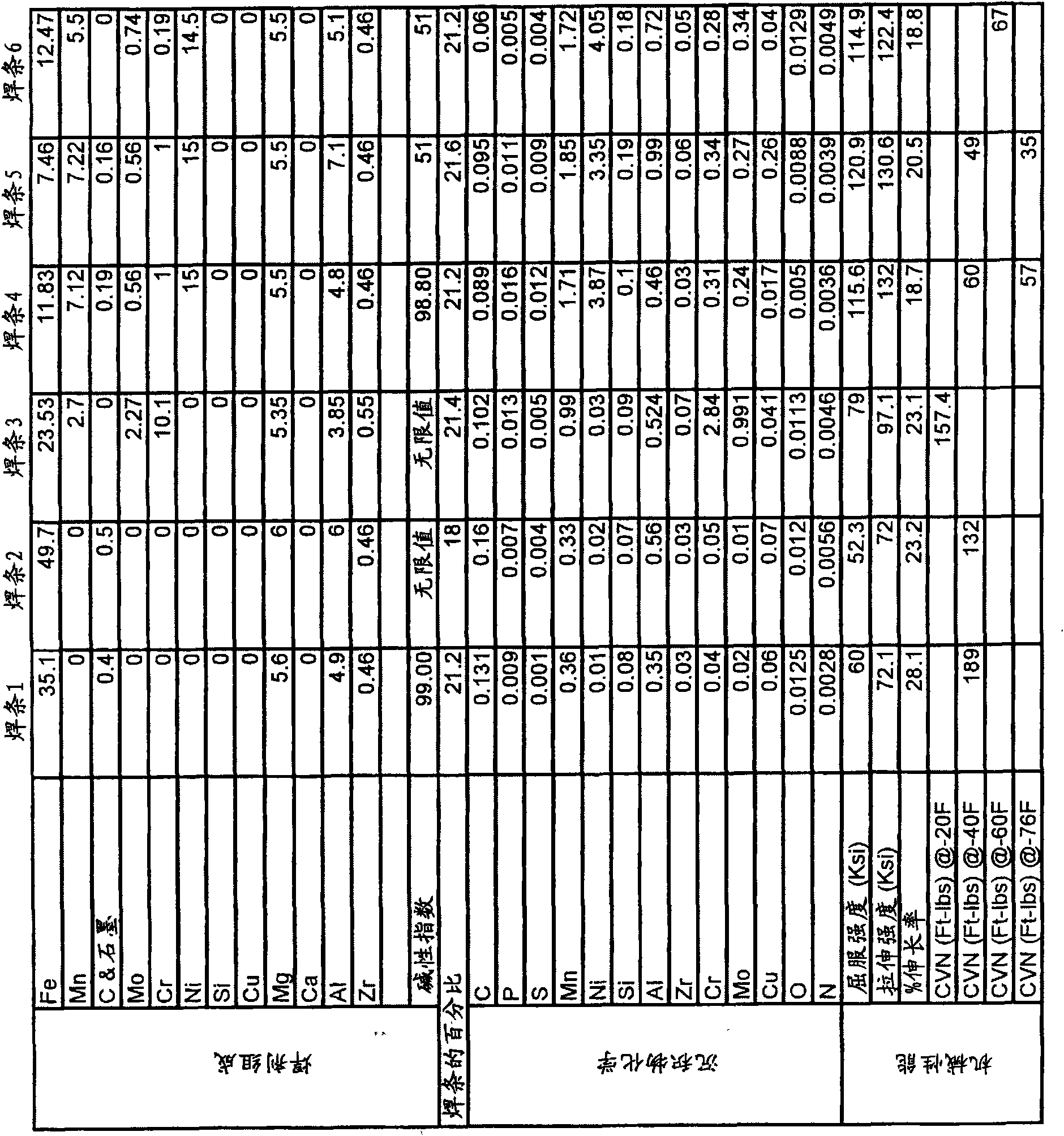

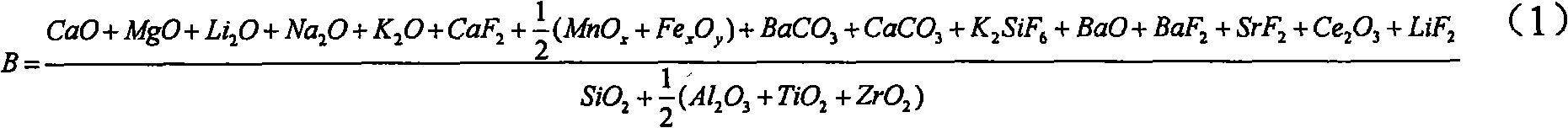

[0012] As discussed in detail below, welding wires include various features that can provide desirable performance and weldability. For example, with certain embodiments of welding wire, the resulting weld includes an increased level of impact toughness. In addition, embodiments of the welding wire also include components that lend themselves to welding in various locations and situations. Some wire embodiments, such as those discussed below, are believed to include "all position" capabilities and substantially lower spatter than self-shielded wires. Therefore, welding wire can be used in applications that require welding "in all places", such as joining pipelines and structural steel buildings. These characteristics are believed to be a result of the wire composition and the method of welding with the described wire embodiments. For example, embodiments of the welding wire include increased concentrations of aluminum and overall components configured to produce a basic slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com