Fuel pump

A technology of fuel pumps and fuel oils, applied in the direction of pumps, pump components, cross-flow pumps, etc., can solve the problems of surface treatment tolerances, high manufacturing costs of fuel pumps, etc., and achieve the effects of avoiding damage, high strength, and small manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

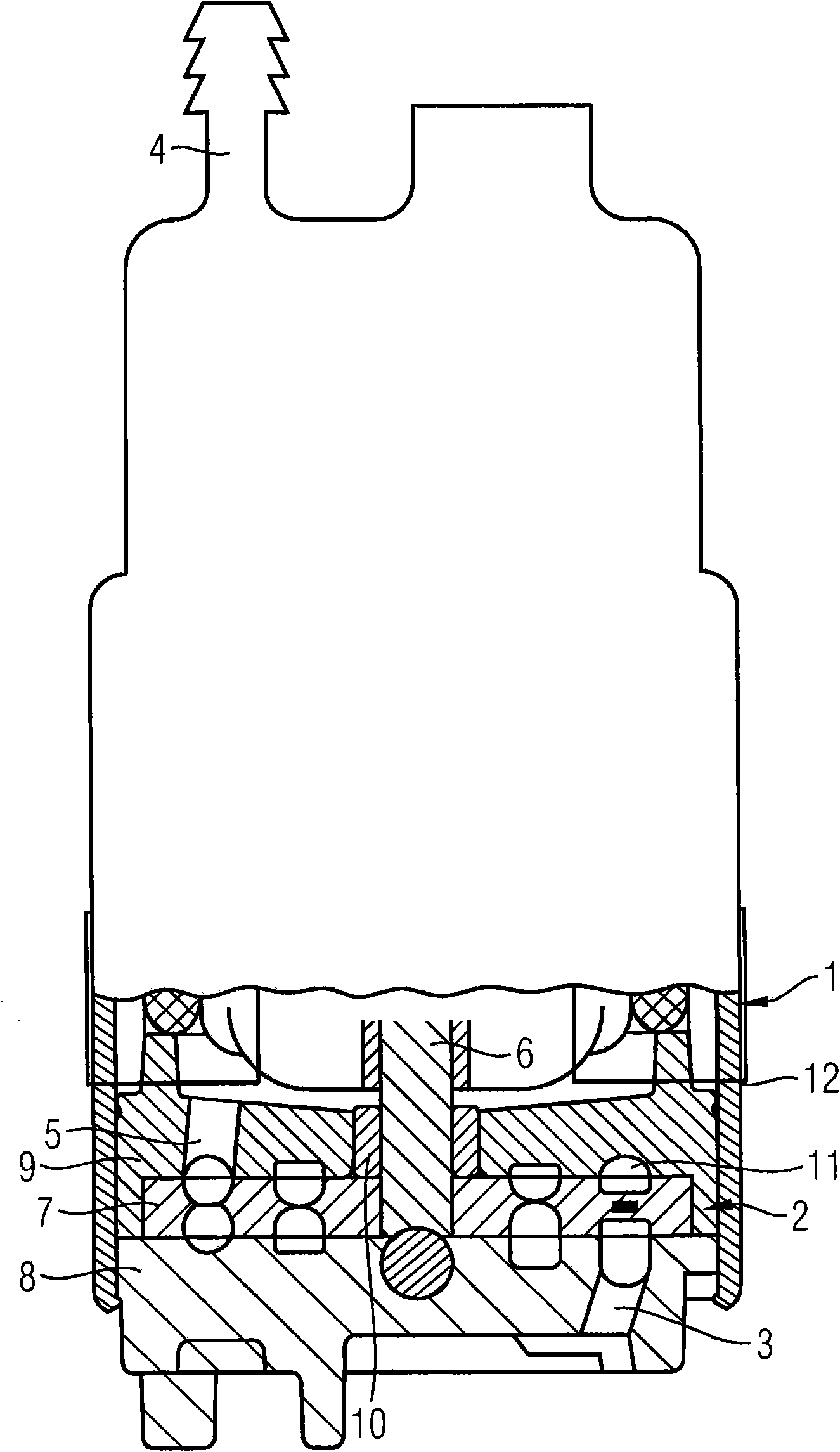

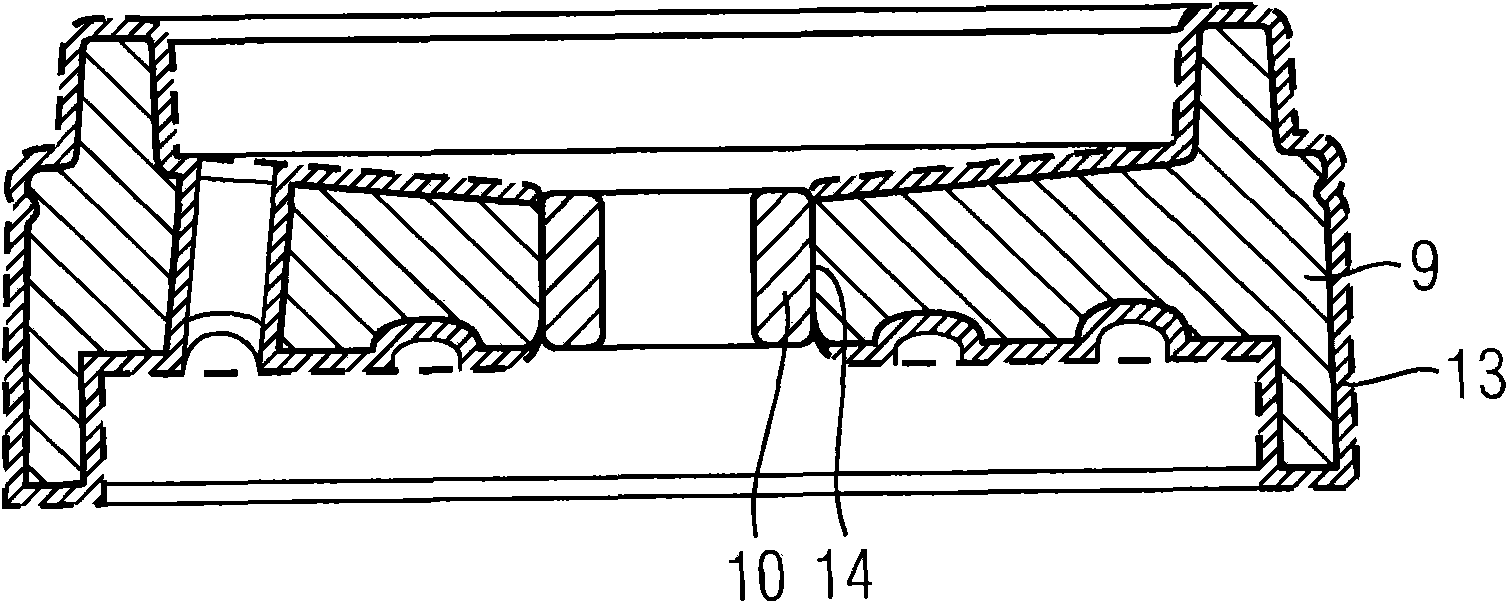

[0014] figure 1 A fuel pump is shown with a pump stage 2 driven by an electric motor 1 . The fuel pump has an inlet 3 arranged on the pump stage 2 and an outlet bushing 4 arranged on the side of the electric motor 1 facing away from the pump stage 2 . The fuel sucked in through the inlet 3 of the pump stage 2 is delivered to the outlet sleeve 4 via the electric motor 1 via the outlet 5 of the pump stage 2 . A drain line, not shown, leading to the internal combustion engine can be connected to the outlet sleeve 4 . The pump stage 2 has an impeller 7 fastened to the shaft 6 of the electric motor 1 and is designed as a side-channel pump. The impeller 7 is held rotatably between the two housing parts 8 , 9 of the pump stage 2 . For mounting the shaft 6 an insert 10 is fastened in one of the housing parts 9 as a bearing sleeve. One of the housing parts 8 has an inlet 3 and the other housing part 9 has an outlet 5 . The impeller 7 and the housing parts 8 , 9 have a delivery cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com