Hometex cloth with water and oil resistance and easy decontamination and manufacturing process thereof

A waterproof and oil-proof, production process technology, applied in textiles and papermaking, textile material processing, devices for coating liquids on surfaces, etc. , to overcome the rough and dry feel, maintain the plump and soft effect, and achieve the effect of excellent water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

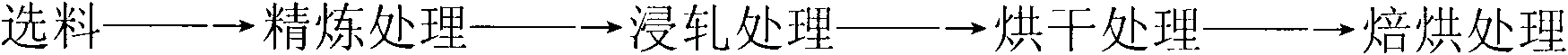

[0014] Such as figure 1 As shown, an example is given for description:

[0015] Choose 66-type dyed plush nylon with a plush thickness of 0.6-1.8dtex and a length of 0.2-1.3mm as raw material, and white gray cloth as the base cloth for electrostatic flocking to obtain flocked gray cloth; Wash with water for 30 minutes under temperature conditions, then dehydrate, and then use a dryer to dry the dehydrated flocked gray cloth at a temperature of 80°C to 90°C; for padding treatment, first pour the finishing solution into the liquid tank, adjust the rolling The air pressure of the car makes the liquid absorption rate of the cloth controlled at 35-50%; then the cloth passing through the liquid tank is wetted by the finishing liquid, and then the finishing liquid is evenly permeated on the cloth by the pressure of the roll. The process was repeated twice; the composition and dosage of the prepared finishing solution were as follows:

[0016] Components of finishing fluid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com