Vacuum processing system and substrate transfer method

A technology for vacuum processing and substrates, applied in vacuum evaporation plating, conveyor objects, ion implantation plating, etc., can solve the problems of reduced productivity and time-consuming, and achieve the effect of preventing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

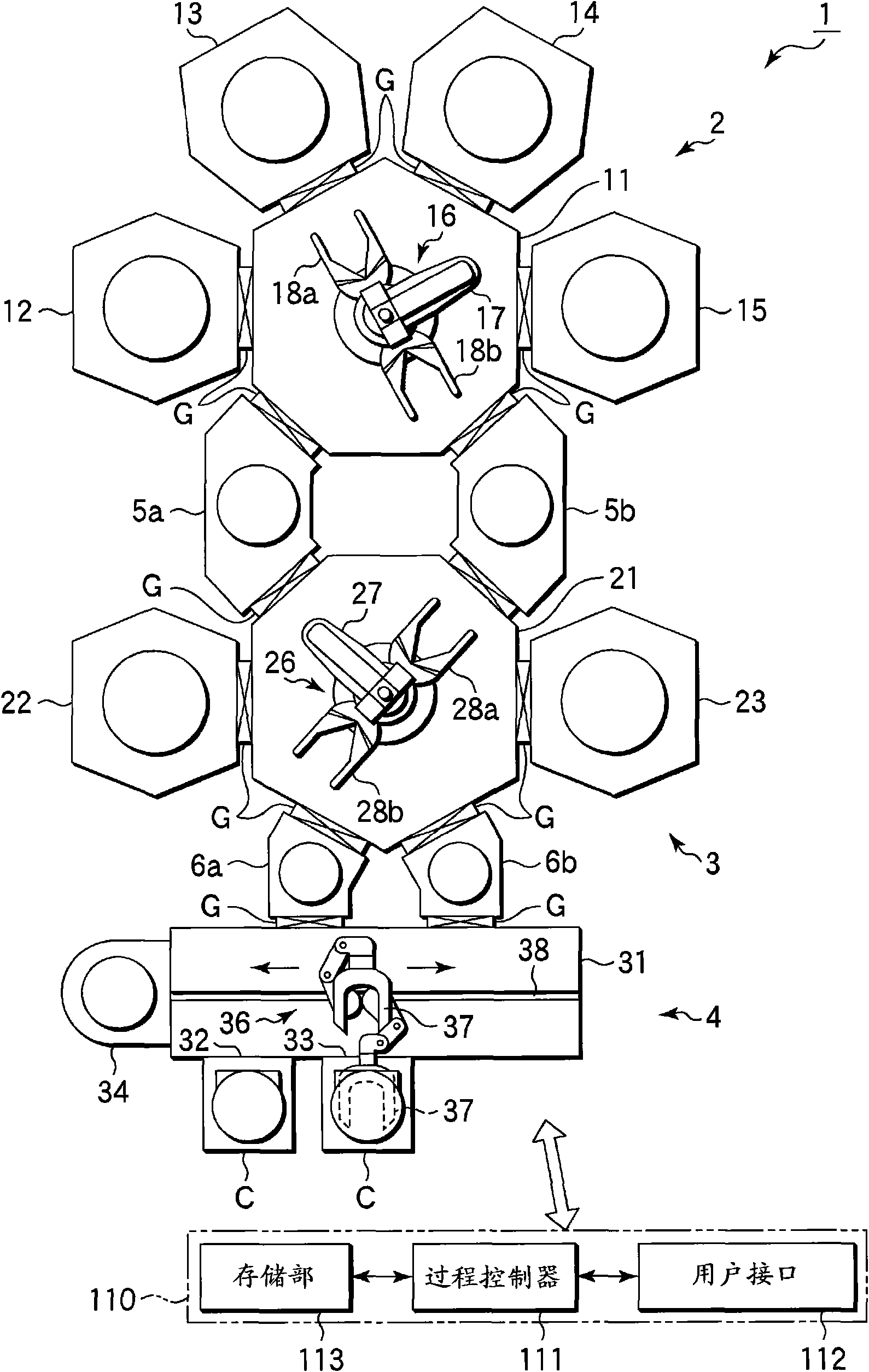

[0023] figure 1 It is a plan view showing a multi-chamber vacuum processing system according to an embodiment of the present invention.

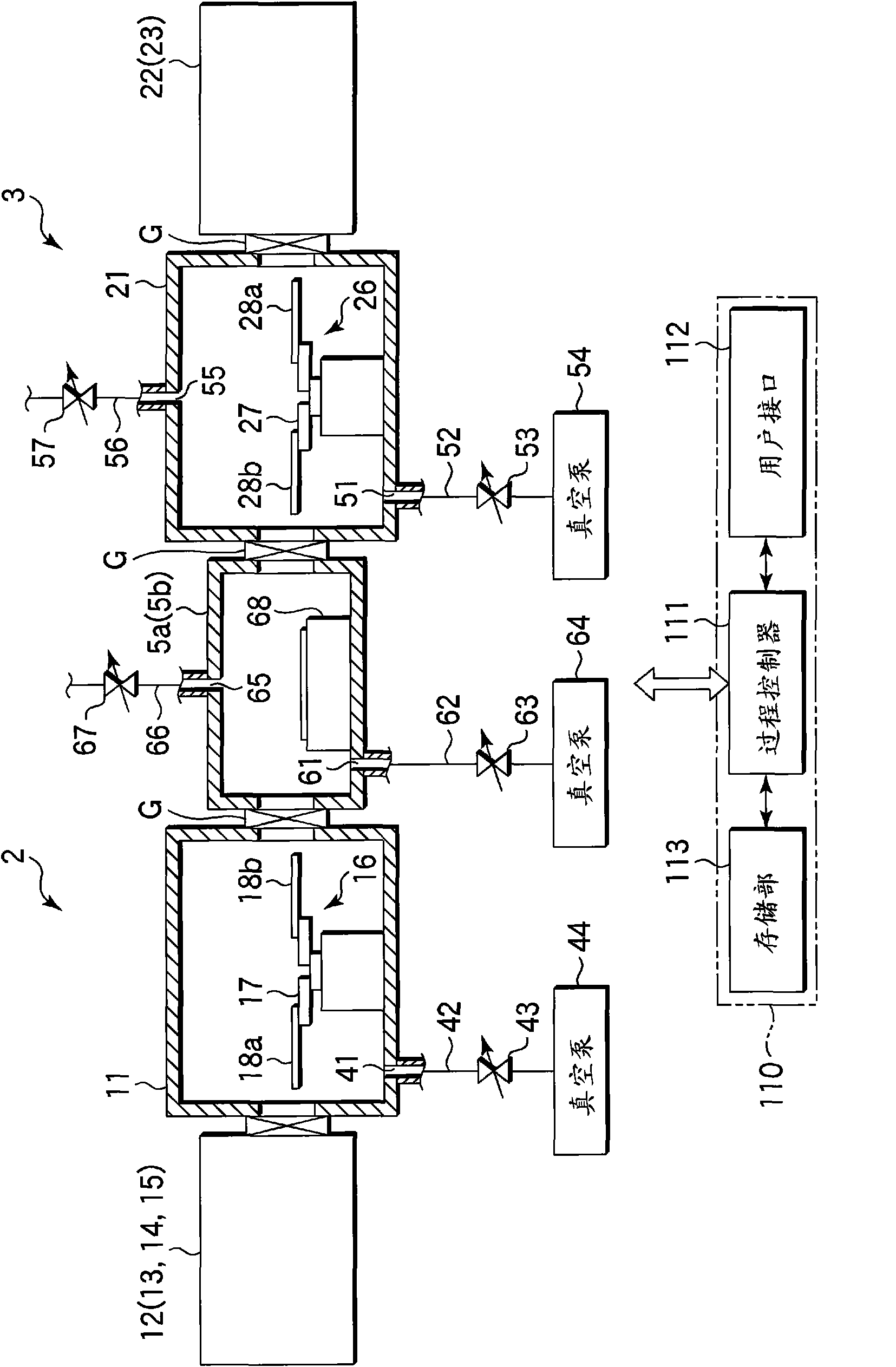

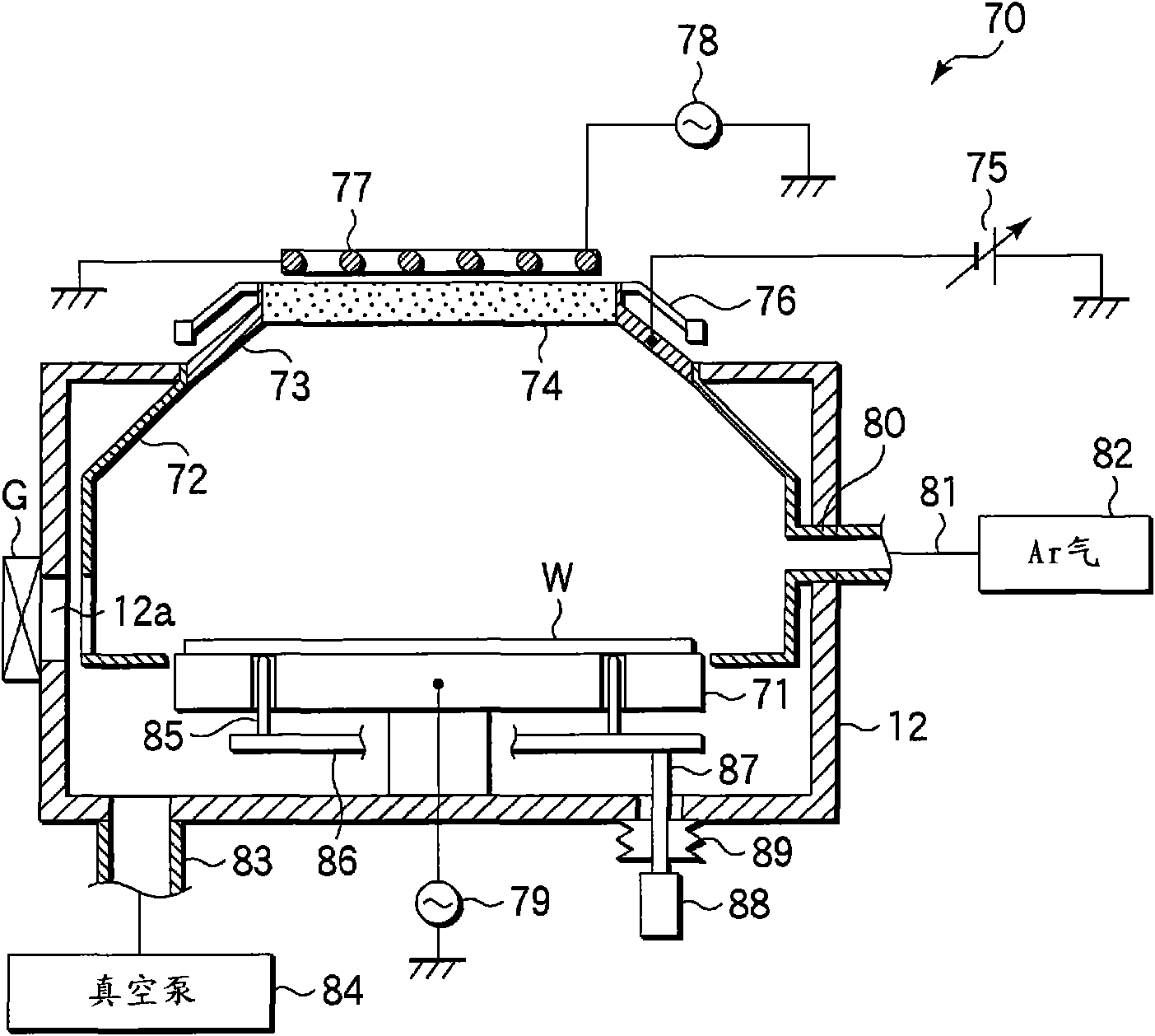

[0024] The vacuum processing system 1 has: a first processing unit 2 with a plurality of processing chambers for processing under high vacuum (low pressure), namely PVD processing, such as sputtering; The second processing part 3 of the chamber; the loading and unloading part 4; membrane.

[0025] The first processing unit 2 has a first transfer chamber 11 having a heptagonal planar shape, and four PVD processing chambers 12 , 13 , 14 , and 15 connected to four sides of the first transfer chamber 11 . On the other two sides of the first transfer chamber 11, the above-mentioned buffer chambers 5a, 5b are respectively connected. The PVD processing chambers 12-15 and the buffer chambers 5a, 5b are connected to each side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com