Construction technique of OGFC on airport expressway

A drainage asphalt, expressway technology, applied in the direction of cohesive pavement paved on site, roads, roads, etc., to achieve the effect of reducing noise, increasing friction coefficient, and improving visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

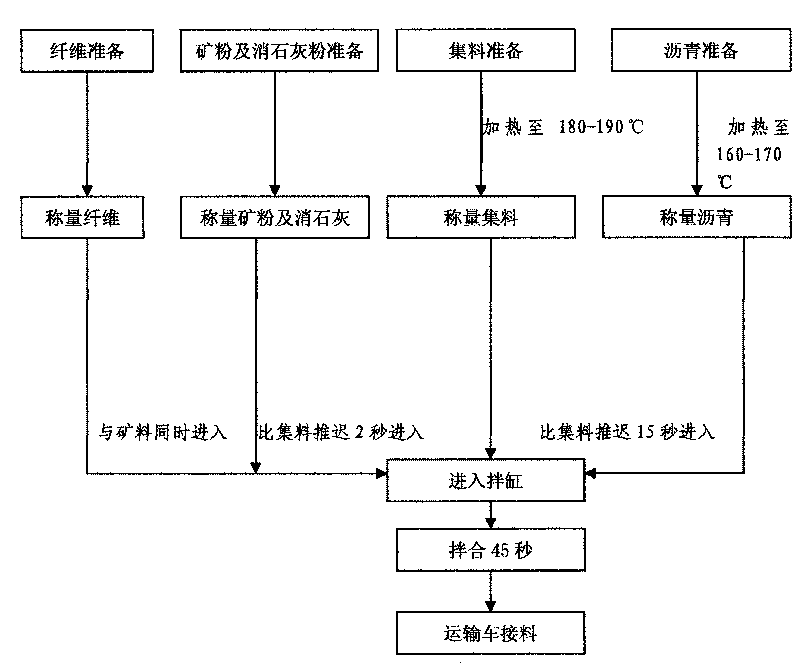

Method used

Image

Examples

Embodiment Construction

[0039] In the embodiment,

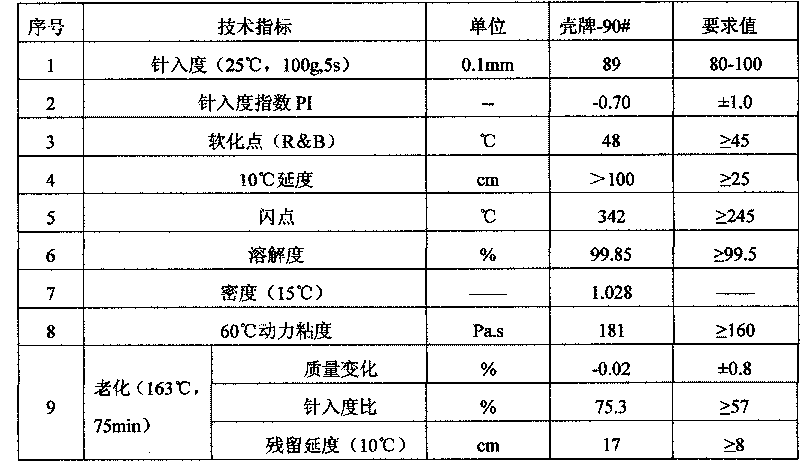

[0040] (1) Asphalt preparation, the asphalt adopts Shell 90# base asphalt, and the modifier is Japanese TPS. The dosage is TPS: base asphalt = 12:88, and the test results of technical properties are shown in Table 1:

[0041] Table 1 Test results of technical properties of 90# asphalt

[0042]

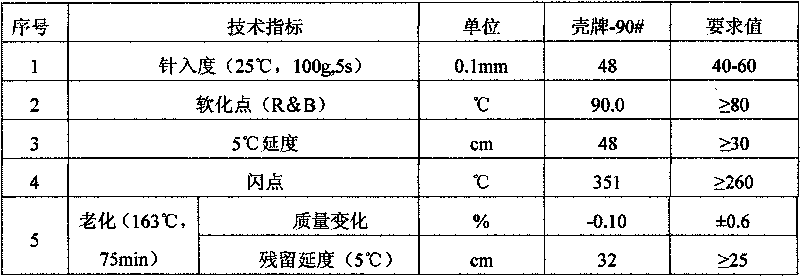

[0043] Test results of technical properties of 90# asphalt (plus TPS)

[0044]

[0045] After adding TPS, the indicators of 90# asphalt changed obviously.

[0046] (2) Aggregate preparation: including coarse aggregate and fine aggregate,

[0047] Among them, the coarse aggregates are diorite gneiss gravels of 9.5-16mm and 4.75-9.5mm, which are washed twice for use, and the throughput of 4.75mm is controlled within 5%. The quality and technical requirements of coarse aggregate are shown in Table 2:

[0048] Table 2 Coarse aggregate quality technical requirements

[0049]

[0050]

[0051] The fine aggregate is made of limestone machine-made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com