Automatic control reverse pushing-type multilayer color concrete slip-form paver

A colored concrete, reverse push technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of increased driving resistance, inability to descend, insufficient mixture, etc., to achieve simple operation control, reduce starting load, and ensure reasonable distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

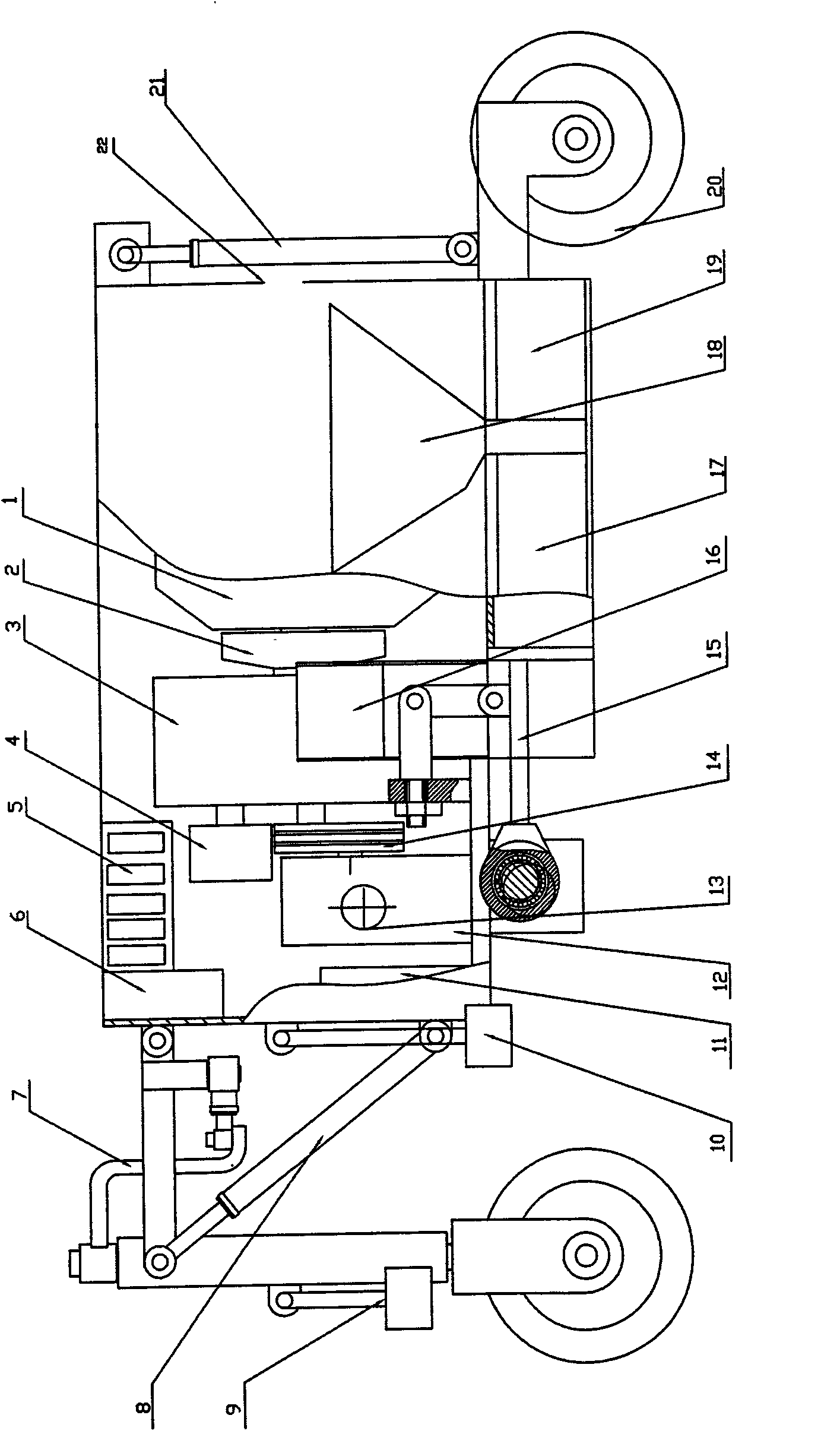

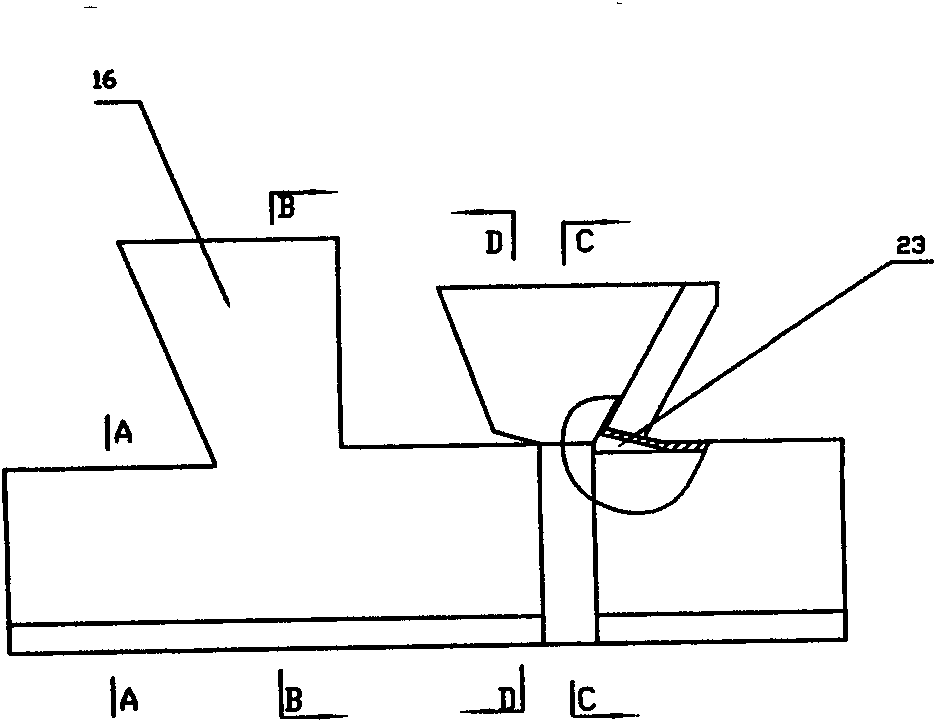

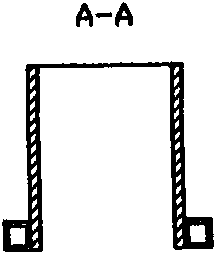

[0022] Such as figure 1 , figure 2As shown, the slipform paving equipment is composed of a feeding mechanism, a power and transmission mechanism, an adjusting mechanism, an electrical system and accessories installed on the frame 22. The feeding mechanism includes an eccentric feeding mechanism 15, a base material hopper 16, Base material molding die 17, color material hopper 18 and multi-layer color material molding die 19, eccentric feeding mechanism 15, base material hopper 16, base material molding die 17, color The material hopper 18 and the multi-layer color material forming die 19, the base material hopper 16 and the bottom of the color material hopper 18 communicate with the base material forming die 17 and the multi-layer color material forming die 19 respectively; the power and the transmission mechanism include the engine 1, Clutch 2, multi-shaft gearbox 3, transmission belt 14, reversing reducer 12, transmission chain 13, eccentric shaft of eccentric feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com