Automatic detection system for oil drilling tools

An automatic detection and oil drilling technology, which is applied in the direction of measuring devices, manufacturing tools, cleaning methods and appliances, etc., can solve the problems of uneven detection level and lack of scale, so as to ensure safe use, improve standardization, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

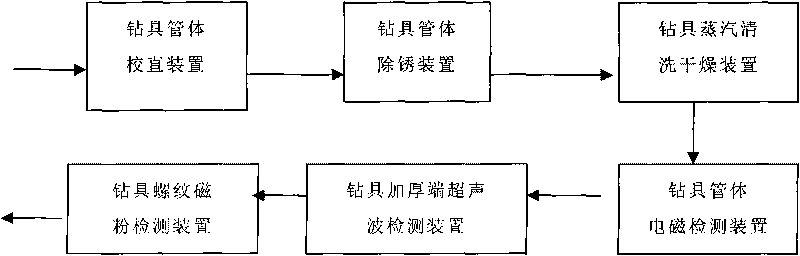

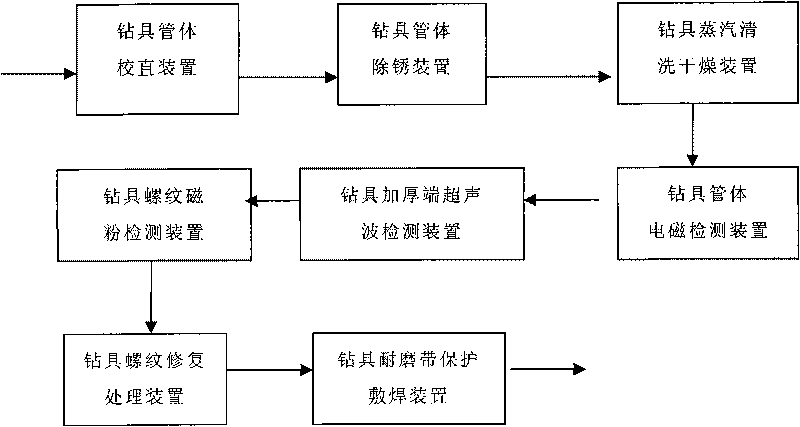

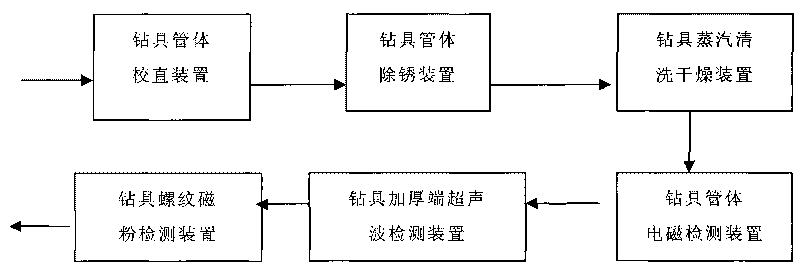

[0023] figure 1 It is a structural schematic diagram of the first embodiment of the automatic detection system for oil drilling tools. As shown in the figure, the oil drilling tool automatic detection system consists of a drilling tool body straightening device, a drilling tool body rust removal device, a drilling tool steam cleaning and drying device, a drilling tool body electromagnetic detection device, and an ultrasonic It is composed of a detection device and a drilling tool thread magnetic particle detection device. The various devices are sequentially connected through transmission lines to form the automatic detection system for oil drilling tools. The transmission line can be realized by adopting existing technologies such as conveyor belts or conveyor rollers.

[0024] The drilling tool pipe body straightening device adopts an advanced stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com