Power frequency zero-flux mini-current sensor for capacitive equipment dielectric loss on-line monitoring

A technology of capacitive equipment and zero magnetic flux, which is applied in the direction of measuring current/voltage, measuring electric variables, voltage/current isolation, etc., can solve the problems of complex sensor structure, difficulty in manufacturing and high cost, and achieve simple internal structure and good performance. On-site anti-interference ability and high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

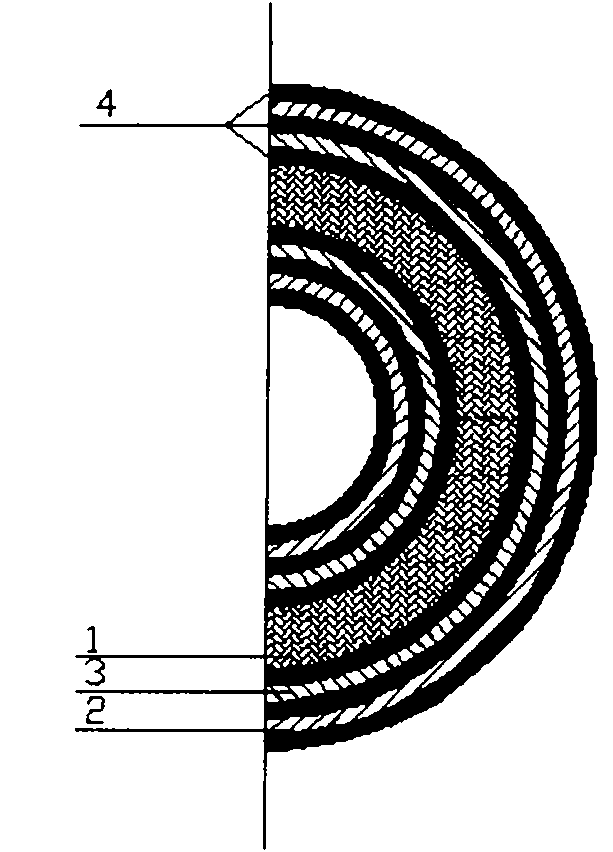

[0026] refer to figure 1 The internal physical structure of a power frequency zero-flux small current sensor for on-line monitoring of dielectric loss of capacitive equipment includes a working magnetic core 1 on which a secondary side coil 2 and a detection coil 3 are wound. The specific winding structure is to use enameled wire to wind the detection coil 3 on the working magnetic core 1, and then use the enameled wire to wind the secondary side coil 2 in the opposite direction on the detection coil 3, between the secondary side coil 2 and the detection coil 3, A shielding layer 4 is provided between the detection coil 3 and the working magnetic core 1 .

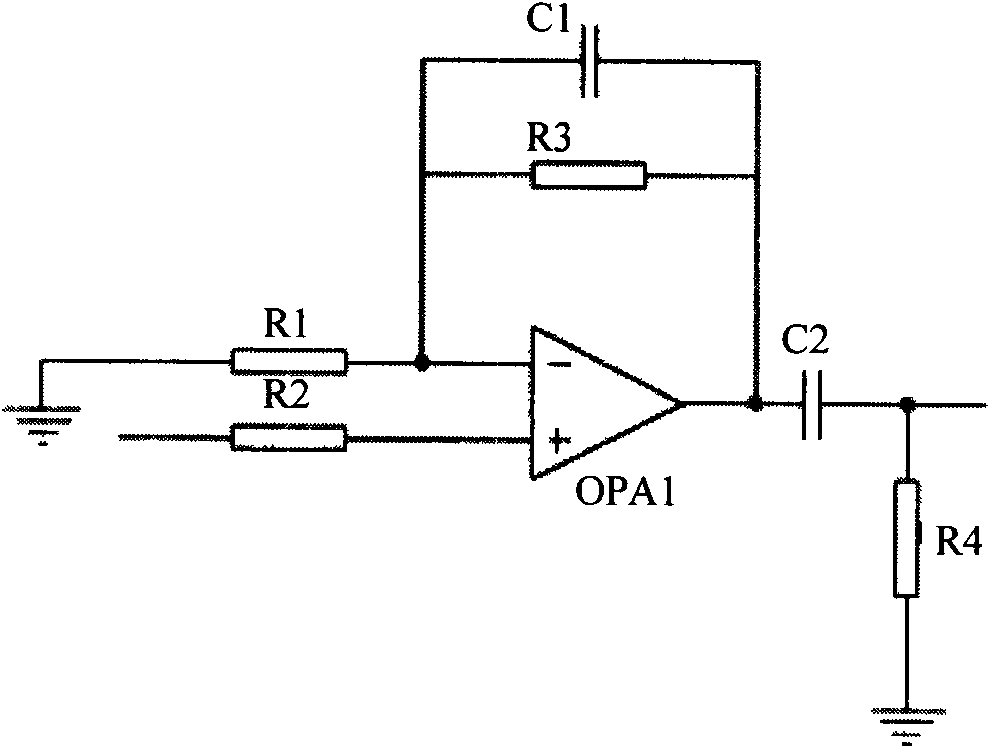

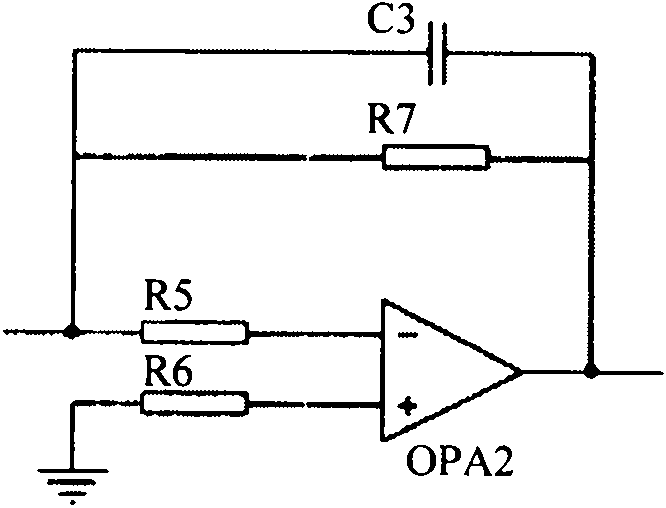

[0027] refer to figure 2 , is a schematic diagram of the sensor principle of the present invention, wherein the detection coil 3 is connected to the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com