Split turbocharged speed reducer differential electric driver

A technology of supercharger reducer and electric drive motor, which is applied to electric components, electrical components, electromechanical devices, etc., can solve the adverse effects on the overall performance and life of electric vehicles, the large noise of the drive shaft and the axle after deceleration, and the lack of climbing ability. and other problems, to achieve the effect of strengthening the climbing ability, increasing the output torque, and reducing the connection links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

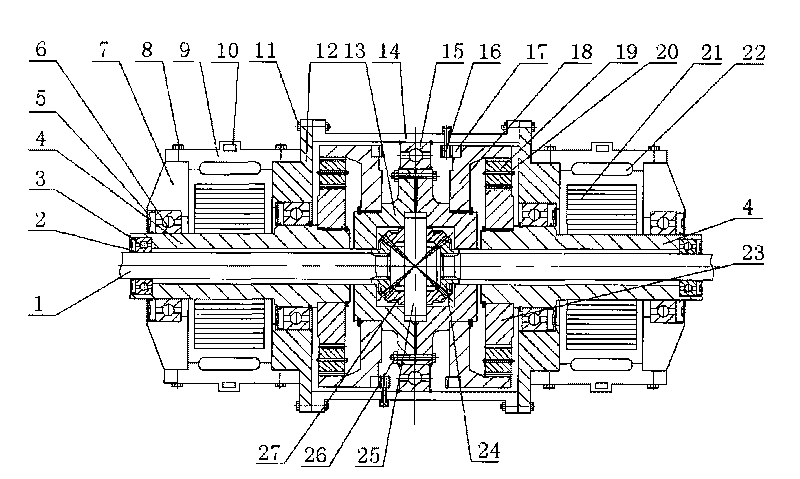

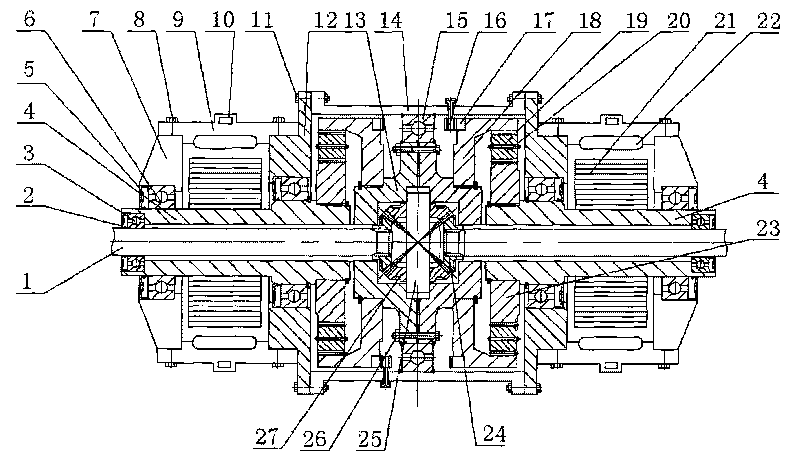

[0014] A kind of split type turbocharger reducer differential electric drive machine reference in this embodiment figure 1 , including the motor housing 9 and the motor shaft 4, and also includes the deceleration booster housing 14 fixedly connected to the motor support 12, the differential gear housing 13 in the housing and the deceleration booster housing 14 are connected and fixed by bearings 15, The outer periphery of the motor shaft 4 is provided with a main drive gear 23 fixedly connected with it, and the main drive gear 23 is in transmission connection with the main drive planetary gear 19 provided on the outer periphery through the main drive planetary gear shaft 20, and the main drive planetary gear 19 is meshed and connected with the differential at the same time. The worm gear final reduction gear 18 that is fixedly connected to the gearbox housing 13, the worm gear final reduction gear 18 is connected to the speedometer gear sensor 16 through the speedometer active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com