Anti-explosion cooling purifying device for hydrogen reducing furnace

A purification device and reduction furnace technology, applied in the direction of valve devices, furnaces, muffle furnaces, etc., can solve problems such as troublesome, incapable tail hydrogen purification treatment, blocked pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

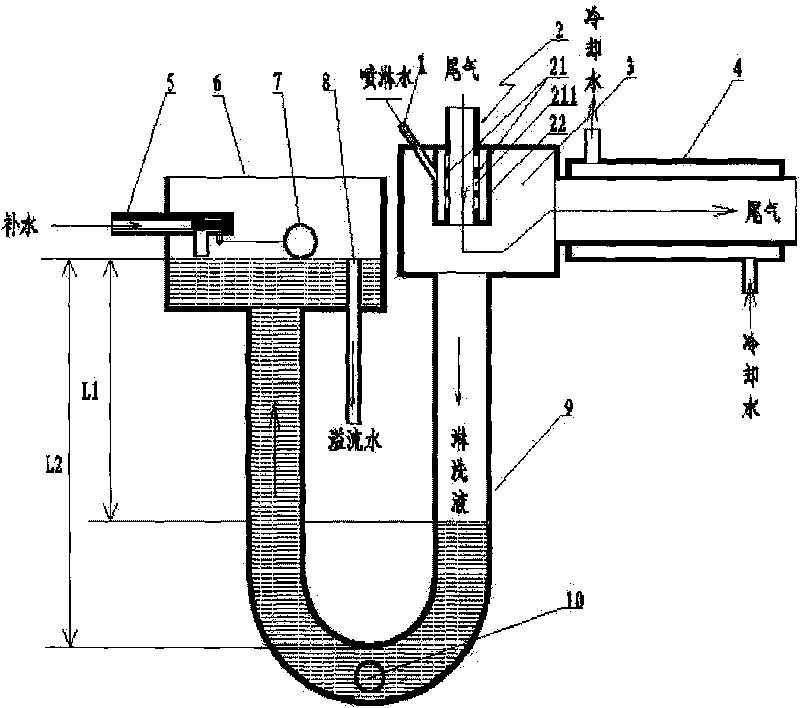

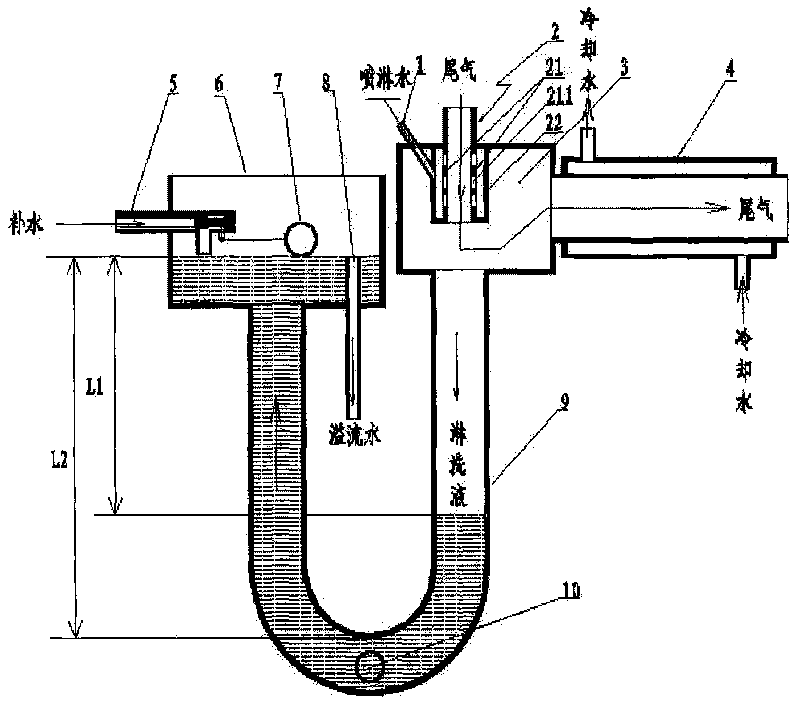

[0020] like figure 1 As shown, this explosion-proof cooling and purification device for hydrogen reduction furnace of the present invention is mainly composed of spray water inlet pipe 1, spray water jacket 2, explosion-proof buffer chamber 3, cooling water jacket 4, water supply pipe 5, exposure The buffer tank 6, the float valve 7, the overflow pipe 8, the U-shaped connecting pipe 9 and the sewage pipe 10 are composed. The spray water jacket 2 is arranged on the upper part of the explosion-proof buffer chamber 3, and its inner jacket 21 communicates with the tail gas pipe of the hydrogen reduction furnace, and the wall of the inner jacket 21 is designed with several small holes 211. The spray water inlet pipe 1 is connected to the outer coat 22 of the spray water jacket 2 and communicates with the interlayer space between the inner jacket 21 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com