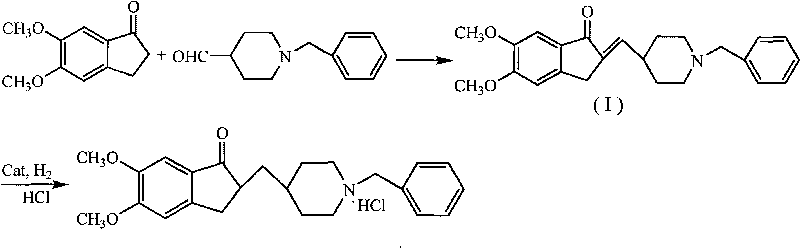

Catalyst for hydrogenation reaction of donepezil hydrochloride key intermediate and application thereof

A technology of donepezil hydrochloride and hydrogenation reaction, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the problem of high cost of palladium carbon catalyst, and achieve easy control of operating conditions , stable activity and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Catalyst Pd / Al is prepared by impregnation method 2 o 3

[0015] 30g of palladium nitrate was heated and dissolved in 100ml of 1% nitric acid aqueous solution, and 100g of γ-Al was added 2 o 3 , stirred evenly, soaked overnight, dried in a drying oven at 110°C for 20h, roasted in a muffle furnace at 550°C for 5h, and reduced with hydrogen at 400°C and 1.0MPa for 2h to obtain the desired catalyst. The weight composition of the catalyst is: Contains palladium 12.3%, contains Al 2 o 3 87.7%.

Embodiment 2

[0016] Embodiment 2: Catalyst Ni / Al is prepared by impregnation method 2 o 3

[0017] Heat and dissolve 60g of nickel nitrate in 100ml of deionized water, add 100g of γ-Al 2 o 3 , stirred evenly, impregnated overnight, dried in a drying oven at 110°C for 20h, roasted in a muffle furnace at 550°C for 5h, and reduced with hydrogen at 400°C and 1.0MPa for 2h to obtain the desired catalyst. The weight composition of the catalyst is 12.4% nickel, containing Al 2 o 3 87.6%.

Embodiment 3

[0018] Embodiment 3: Catalyst Pd-Ni / Al is prepared by kneading and extruding method 2 o 3

[0019] Heat and dissolve 30g of palladium nitrate and 15g of nickel nitrate in 120ml of 1% nitric acid aqueous solution by mass percentage, add 100g of γ-Al 2 o 3 Powder, fully ground until completely mixed evenly, extruded, dried in a drying oven at 110°C for 20h, roasted in a muffle furnace at 550°C for 5h, reduced with hydrogen at 400°C and 1.0MPa for 2h to obtain the desired catalyst. The weight composition of the catalyst is 11.8% palladium, 3.0% nickel, Al 2 o 3 85.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com