Heavy-load type oil-gas spring independent suspension steering drive axle

A technology of steering drive axle and oil-pneumatic spring, which is applied in the field of machinery, can solve problems such as the inability to adjust the ground clearance, affect the handling performance of the vehicle, and affect the stiffness of the entire bridge, etc., to achieve improved maneuverability and stability, compact structure, and improved structure. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

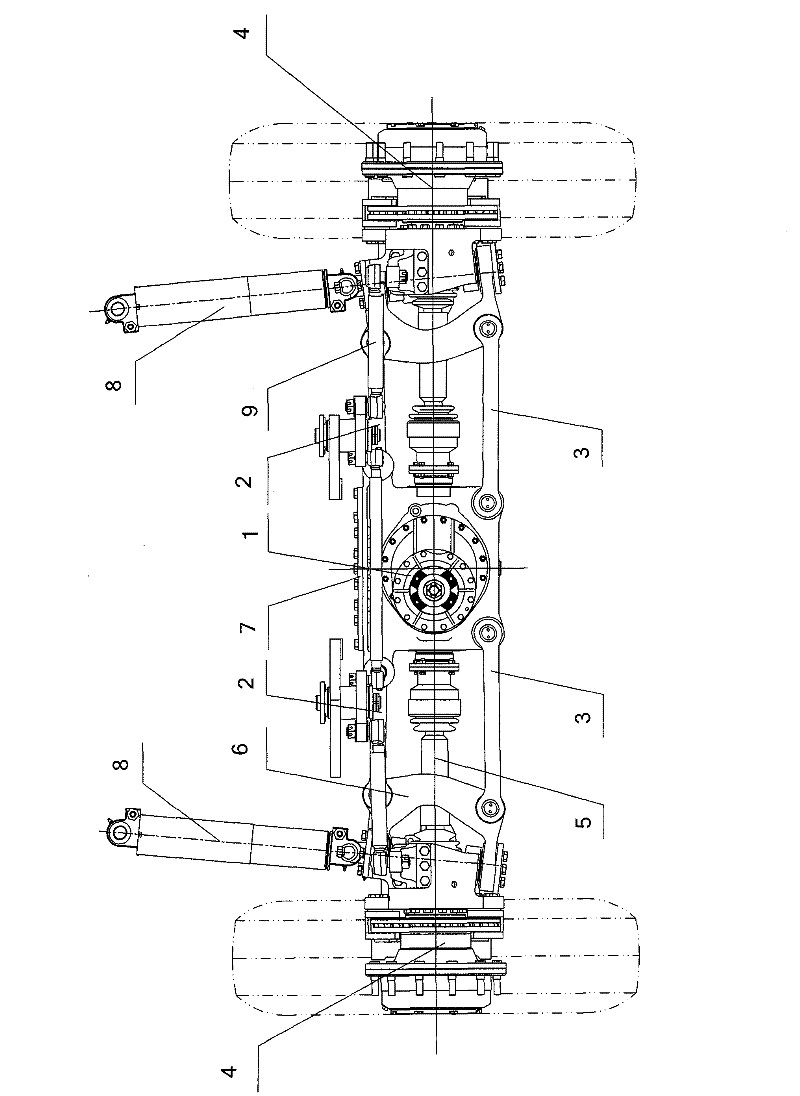

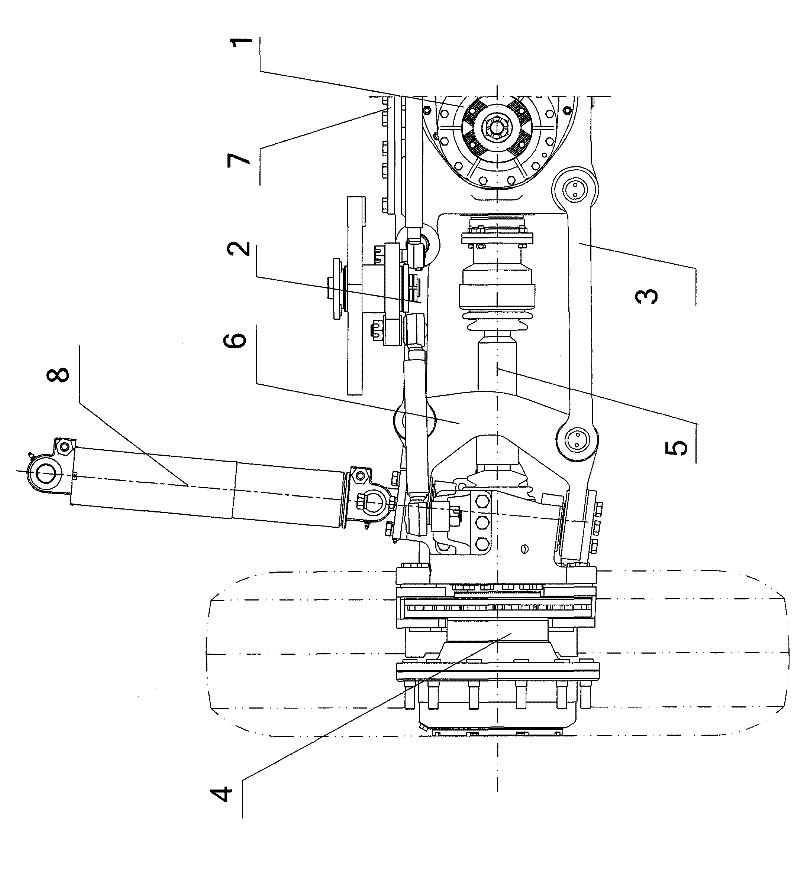

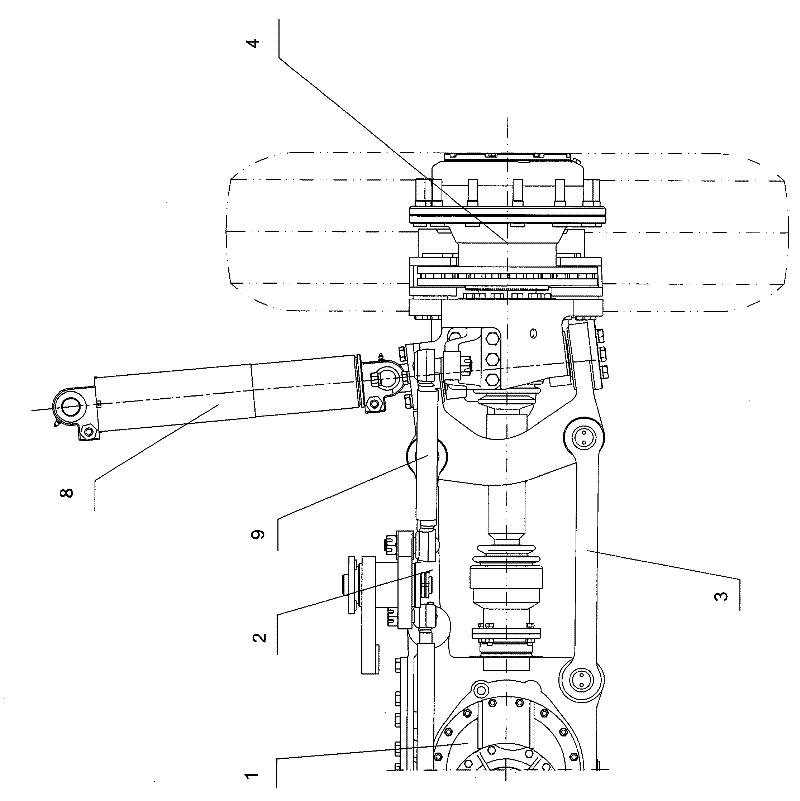

[0033] The invention as Figure 1-6 As shown, it includes central main reducer assembly 1, upper cross arm 2, lower cross arm 3, wheel side reducer assembly 4, double ball cage type constant velocity universal joint transmission shaft 5, steering knuckle seat 6, oil-gas spring 8 and the steering rod system 9, the central final reducer assembly 1 is located at the center of the steering drive axle and is fixedly connected to the vehicle frame 7, the upper cross arm 2, the lower cross arm 3, the wheel side reducer assembly 4, and the double ball cage The constant velocity universal transmission shaft 5, the steering knuckle seat 6 and the oil-pneumatic spring 8 are symmetrically distributed at both ends of the central final drive assembly 1, and the left and right structures are exactly the same.

[0034] Central main reducer assembly 1 such as Figure 7 As shown, it includes a housing 11 , a differential device 12 and an input flange 13 . The central final reducer assembly 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com