Energy-saving air preprocessing method and device thereof

A pretreatment device, energy-saving technology, applied in the direction of biomass pretreatment, biomass post-treatment, biochemical cleaning devices, etc., can solve the problems of low thermal power, poor air heating efficiency, and reduced air supply efficiency, etc. The effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is made on the basis of the utility model patent whose patent number is 200820186662.2 and the title of the invention is "improved air cooling water eliminator device" of the inventor.

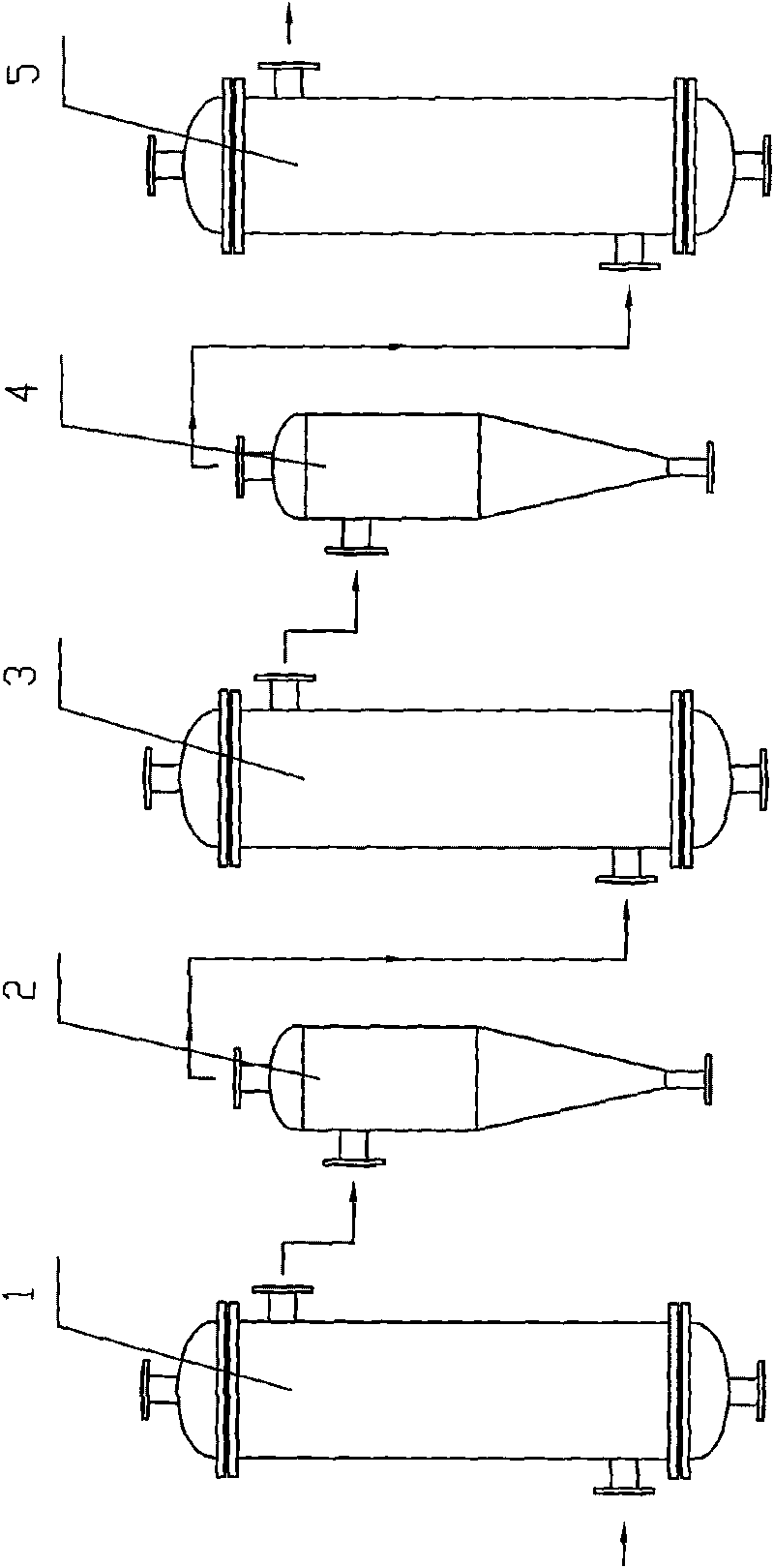

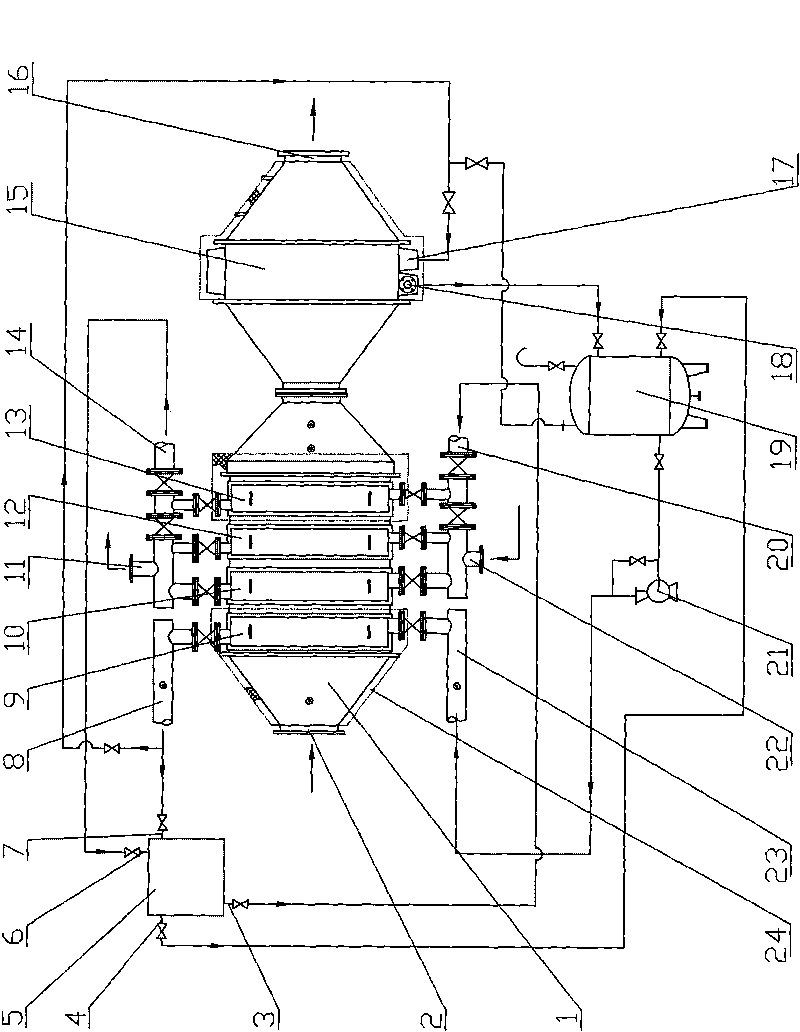

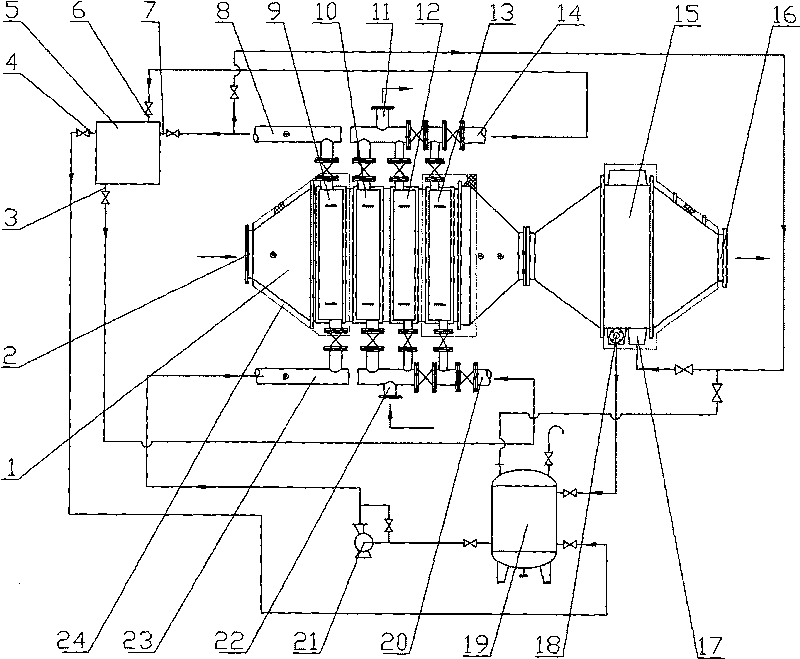

[0029] Such as figure 2 Shown is an energy-saving air pretreatment method. This method passes the high-temperature and high-humidity compressed air from the air compressor into the air cooler and air heater connected in series to make it into low-temperature dry compressed air. In the method of the present invention, the air cooler adopts the finned air cooling water eliminator device 1 in the utility model patent No. 200820186662.2, and the air heater adopts the finned air heater 15. The steps of the method are as follows:

[0030] a. After the high-temperature and high-humidity compressed air enters the finned air-cooled water eliminator device 1, it exchanges heat with the cooling water in the first group of tube boxes 9, and cools the first group of tube boxes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com