Reinforcing and strengthening processing method of chemical grout

A technology of chemical grouting and treatment method, which is applied in the field of engineering construction reinforcement and reinforcement treatment by chemical grouting, can solve the problems such as the inability of cement grout to achieve the effect of infiltration and infusion, the inability to improve the strength of rock mass, and the inability to effectively deal with it. Achieving the effect of avoiding high engineering costs, improving properties, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

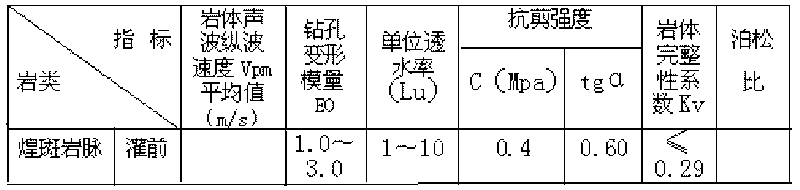

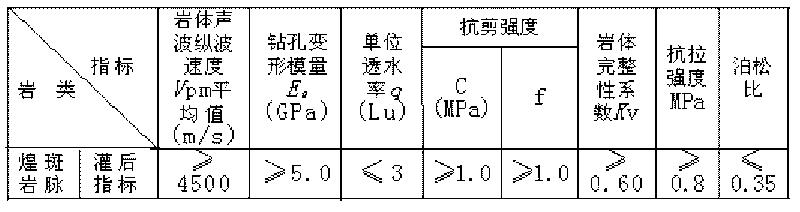

[0046] Located on the Yalong River in western China, there are lamprophyre veins (weak and low-permeability strata) along the river in the base of the spandrel trough on the left bank of the Level 1 hydropower station, extending more than 200m. Lamprophyre dikes are intrusive rocks, weathered under the action of groundwater, weak, dense lithofacies, rock mass permeability coefficient K=n×10 -4 ~10 -6 , and its distribution along the river is from the top of the mountain to more than 100 meters below the foundation of the dam. The mechanical indicators before treatment are shown in Table 2:

[0047] The lamprophyre veins provided during the exploration stage have an average acoustic wave value of 3289m / s, an average deformation modulus of 0.72Gpa, and a permeability coefficient of K=n×10 -4 ~10 -6 cm / s.

[0048] The mechanical properties of lamprophyre dikes before irrigation Table 2

[0049]

[0050] Using conventional cement grouting reinforcement treatment methods or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com