Device for testing sound absorption performance of porous metal material under variable parameter temperature field

A porous metal and testing device technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of high test cost and large test piece area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

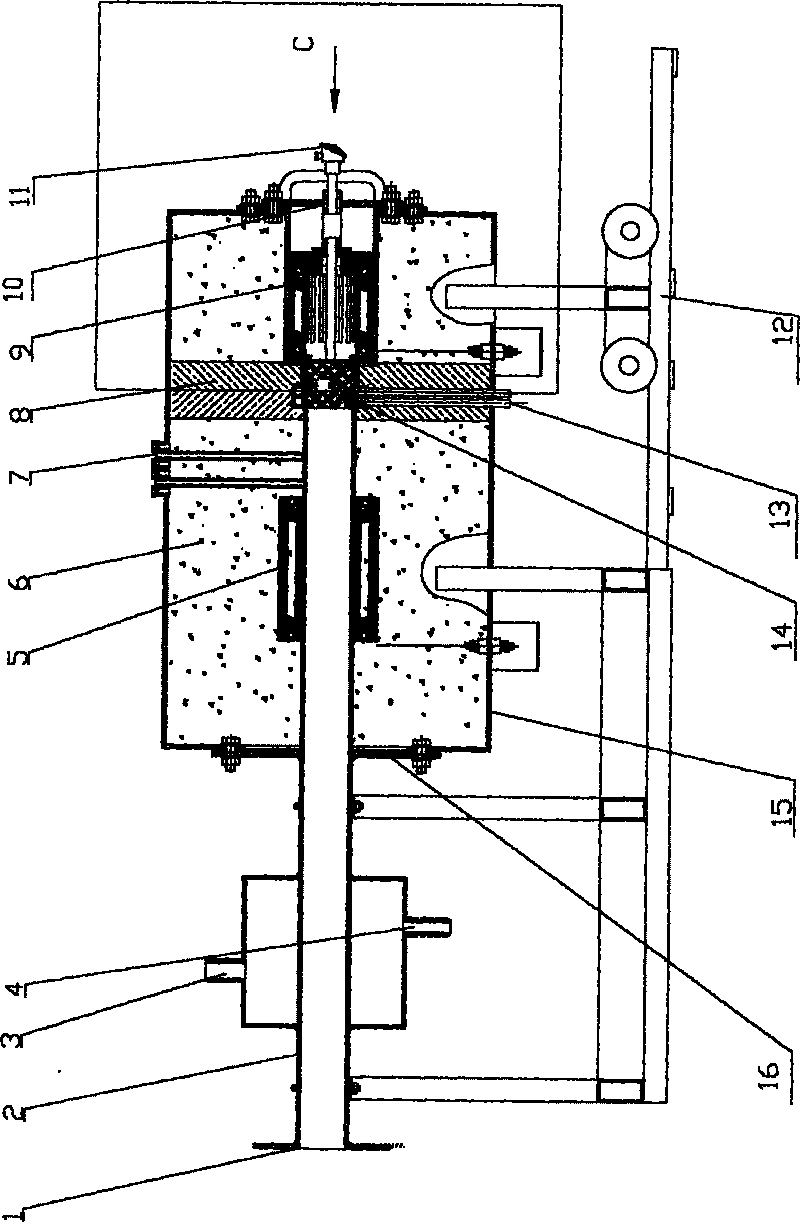

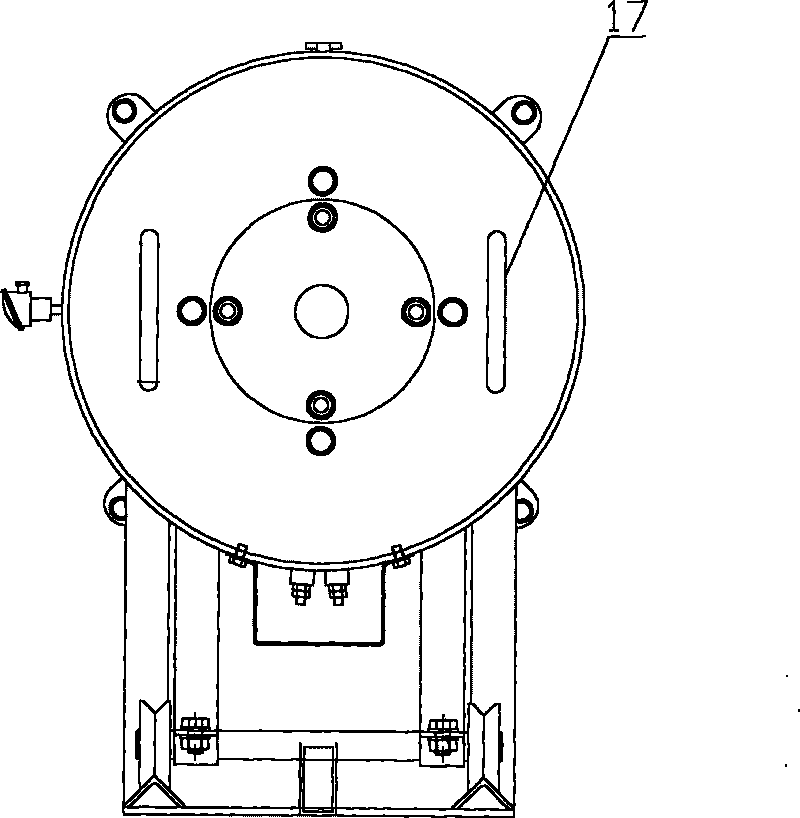

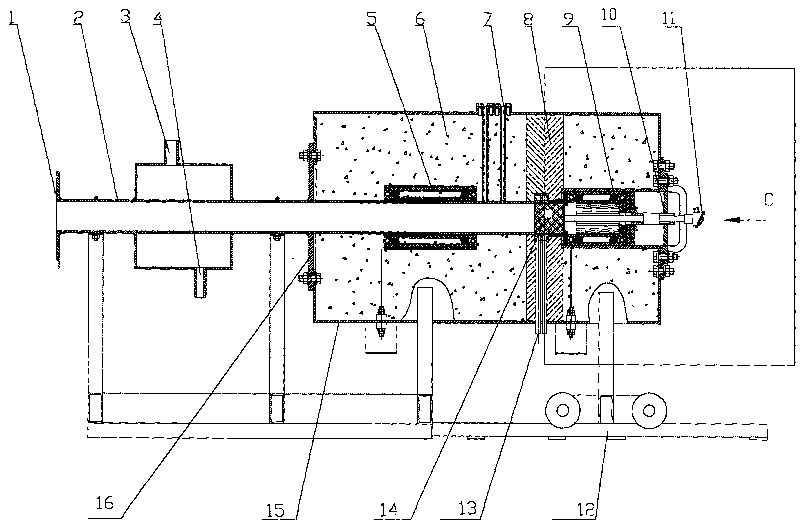

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

[0022] see figure 1 , 2 , a porous metal material sound-absorbing performance testing device under a variable parameter temperature field, comprising a loudspeaker 1, an impedance tube 2, a thermal insulation heating body 5, a test piece heating body 9 and a microphone probe; the low temperature zone of the impedance tube 2 (fixed method The end of flange 16 on the left side) is provided with a speaker 1, and the speaker 1 is used to generate white noise signals; the middle part of the high temperature zone of the impedance tube 2 (the right side of the fixed flange 16) is provided with a thermal insulation heating body 5, which is used to ensure that the internal impedance of the impedance tube 2 The temperature field in the area close to the test piece is uniform; a microphone probe hole is arranged between the heat shield 8 in the high temperature area of the imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com