Method and device for detecting contact resistance of probe

A contact resistance and detection device technology, applied in the direction of measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve problems such as imperceptible, easily damaged standard sheets, and difficult to obtain measured values, so as to ensure measurement performance, Suitable for popularization and application, with good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

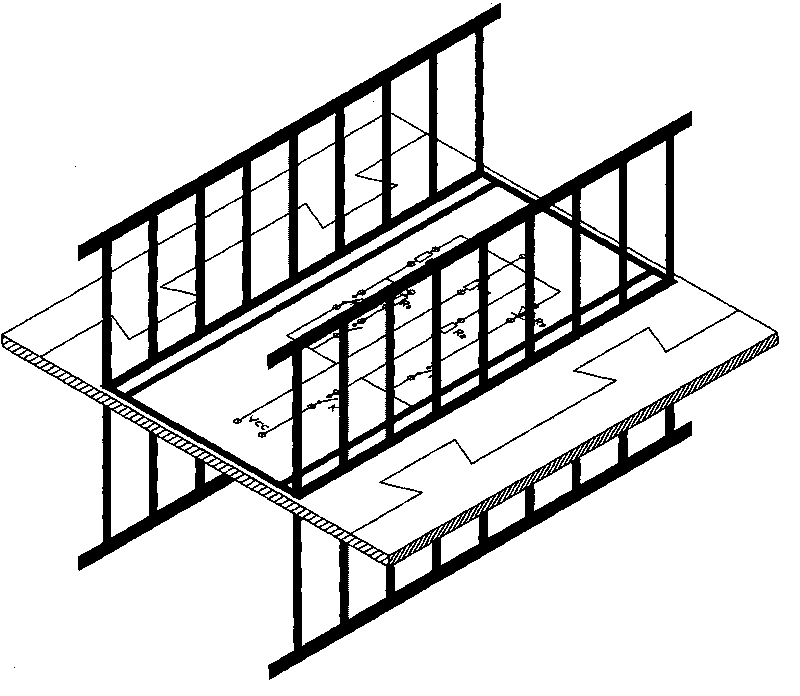

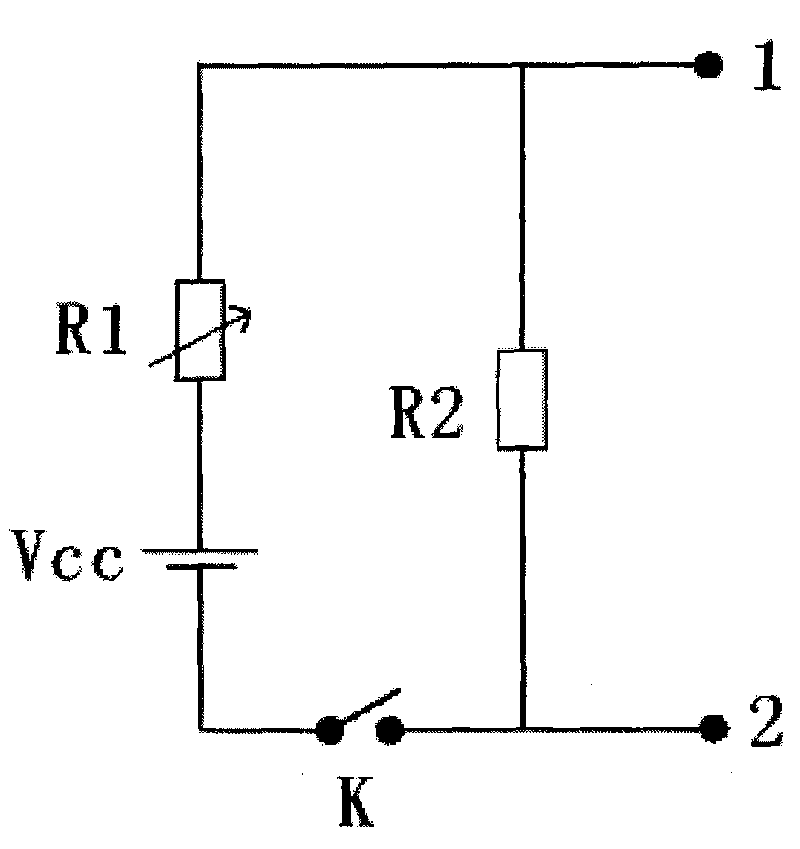

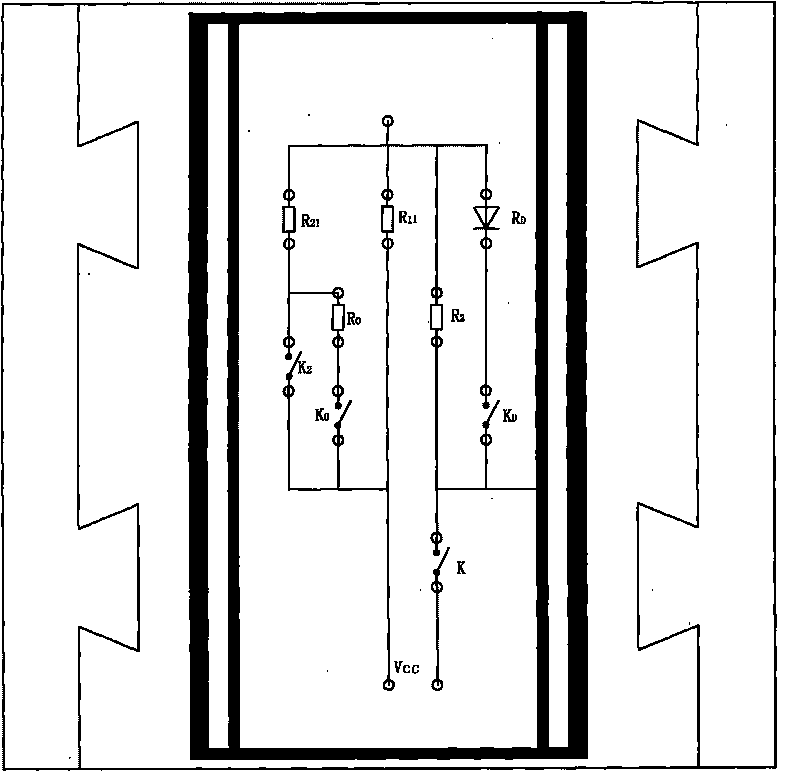

[0038] See attached Figure 1~3 As shown, test on a solar cell test device, the test process is as follows: figure 1 As shown, the test structure is placed between the probes of the solar cell test device, and the first test electrode 1 is in contact with the lower row of probes of the solar cell test device, and the second test electrode 2 is in contact with the upper row of probes. touch;

[0039] Then set the resistance of the rheostat module R1 of the test structure to be R11, test once with a solar cell test device, record the values of relevant electrical performance parameters such as voltage V1 and current I1 obtained from the test; continuously measure 10 times, take the average value, and obtain V1 is 0.3644V, current I1 is 0.7010A;

[0040] Keep the device still, change the resistance of the rheostat module R1 of the test structure to R12, test it once with the solar cell test device, and record the values of relevant electrical performance parameters such as ...

Embodiment 2

[0044] Test on a solar cell test device, the test process is as follows: the test structure is placed between the probes of the solar cell test device, and the first test electrode is in contact with the lower row of probes of the solar cell test device, the second The second test electrode is in contact with the upper row of probes;

[0045] Then set the resistance of the rheostat module R1 of the test structure to be R11, test once with a solar cell test device, record the values of relevant electrical performance parameters such as voltage V1 and current I1 obtained from the test; continuously measure 10 times, take the average value, and obtain V1 is 0.3447V, current I1 is 0.6365A;

[0046] Keep the device still, change the resistance of the rheostat module R1 of the test structure to R12, test it once with the solar cell test device, and record the values of relevant electrical performance parameters such as voltage V2 and current I2 obtained from the current test; co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com