Winding machine with double spinning heads

A technology of winding machine and wire head, which is applied in the field of manufacturing equipment of resin-based composite material pipes, can solve problems such as unstable quality and affecting the service life of pipes, and achieve the effects of easy manufacturing, simple structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

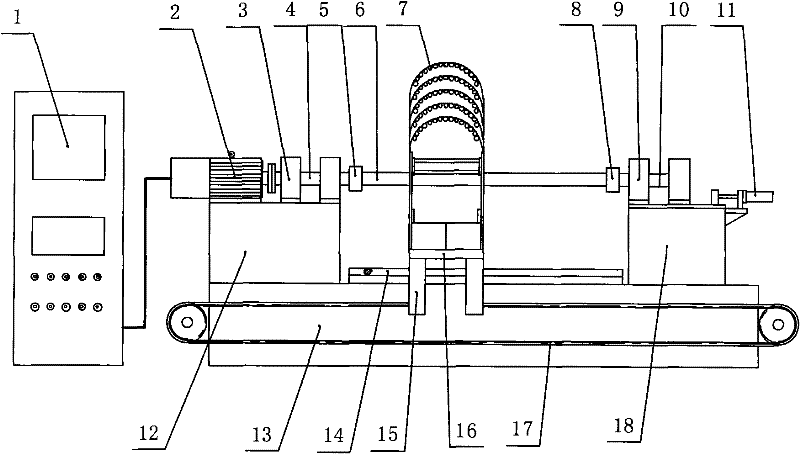

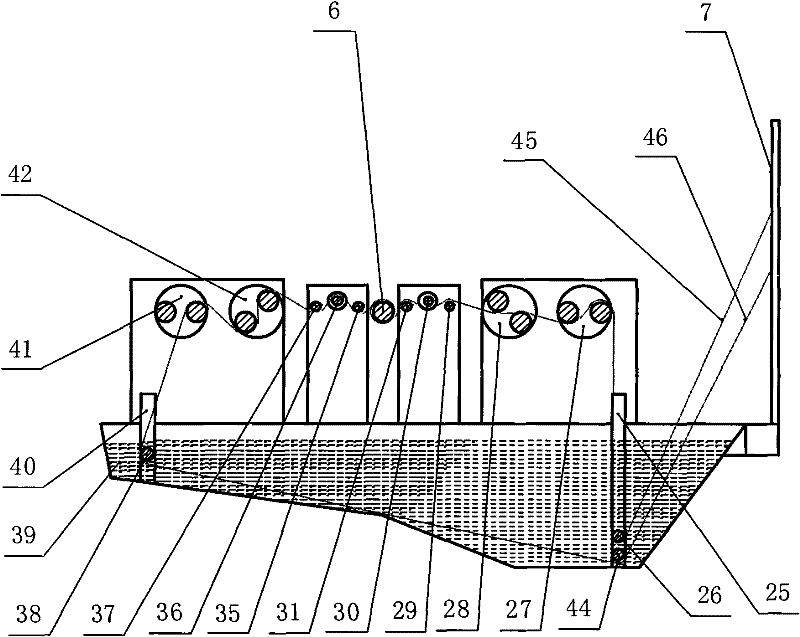

[0013] Depend on figure 1 , figure 2 , image 3 Shown: double wire head winding machine, equipped with control cabinet 1, bedside base 12, bedside 13, bedside base 18, motor 2 is arranged on the bedside base, motor shaft on the bedside base and bedside spindle 4 Connected with each other, the machine head spindle is provided with a mandrel ferrule 5, the bed tail spindle 10 on the bed tail seat 18 is provided with a mandrel ferrule 8, and the bed tail seat top pulls the oil cylinder 11, and the machine tool between the bed head seat and the bed tail seat The body 13 is provided with a slide track 14, and the drive shaft 20 of the winding car is provided outside the machine body under the machine head seat. The two ends of the drive shaft are provided with a main sprocket 23. The motor 21 of the winding car is connected, and the outside of the machine body under the bed end seat is provided with a driven shaft 34 of the winding car, and the two ends of the driven shaft are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com