Method for enriching and separating noble metal in aluminum-containing noble metal liquid by two-step method

A precious metal, two-step technology, applied in the petrochemical field, can solve the problems of short production cycle, high production efficiency and low production efficiency, and achieve the effect of short production cycle, high production efficiency and few steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The present invention will be described in further detail below by way of examples. The purpose is to verify the method and effect of the two-step enrichment and separation of noble metals in aluminum solutions containing noble metals.

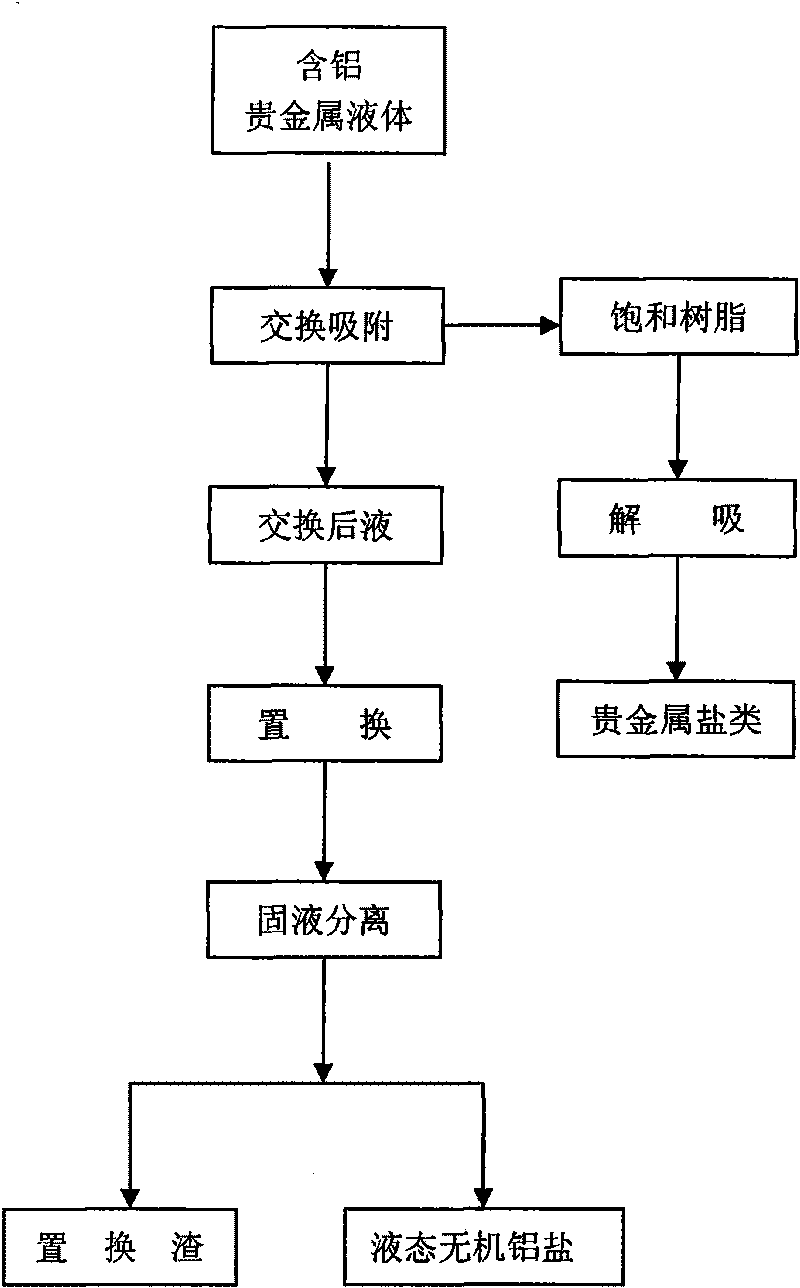

[0024] According to the process flow chart shown in the accompanying drawing:

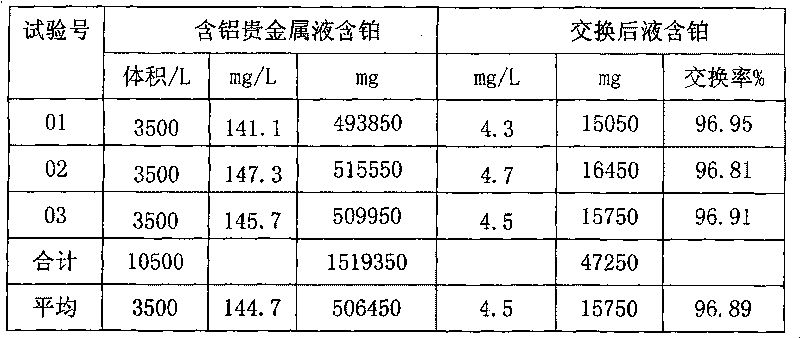

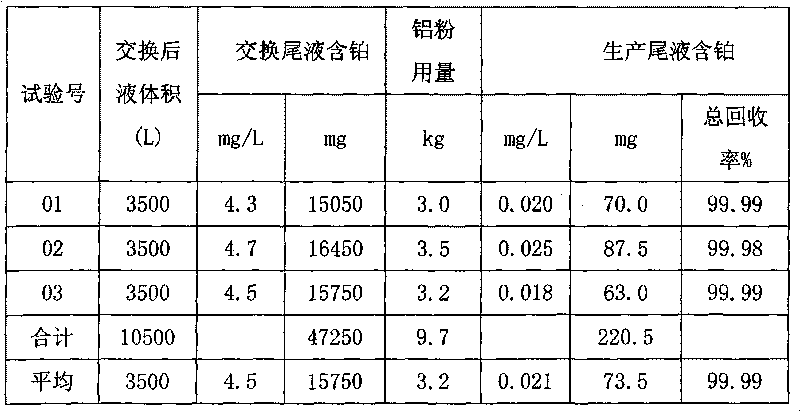

[0025] 1 Take three kinds of aluminum concentration (0.5~3.0mol L -1 ) The liquid containing noble metal platinum anion is the implementation of this case as raw material. Take 3500L of each kind, test its concentration respectively, see Table 1.

[0026] 2 exchanges

[0027] The liquid containing precious metal platinum anion is adsorbed by anion exchange resin:

[0028] The anion exchange resin adopts the commercially available R410 anion exchange resin, and the exchange rate is 80-160L h -1 .

[0029] The exchange effect is shown in Table 1:

[0030] Table I

[0031]

[0032] It can be seen from the above table that industrial operation require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com