Glass color printing tile and production method thereof

A color printing technology for walls and glass, applied in ceramic forming machines, buildings, manufacturing tools, etc., can solve the problems of destroying land resources and ecological balance, rough patterns, non-standard thickness, etc., and achieve the protection of land resources and ecological balance, bright surface , not easy to fade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

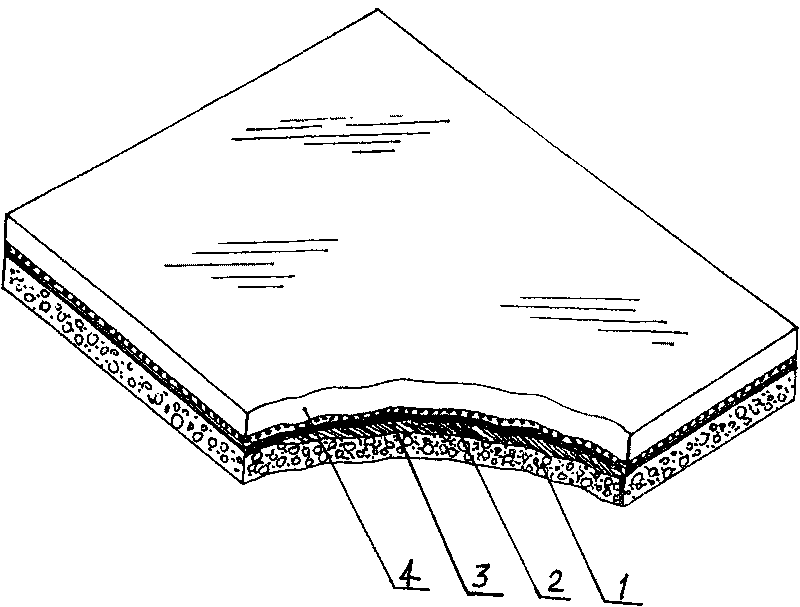

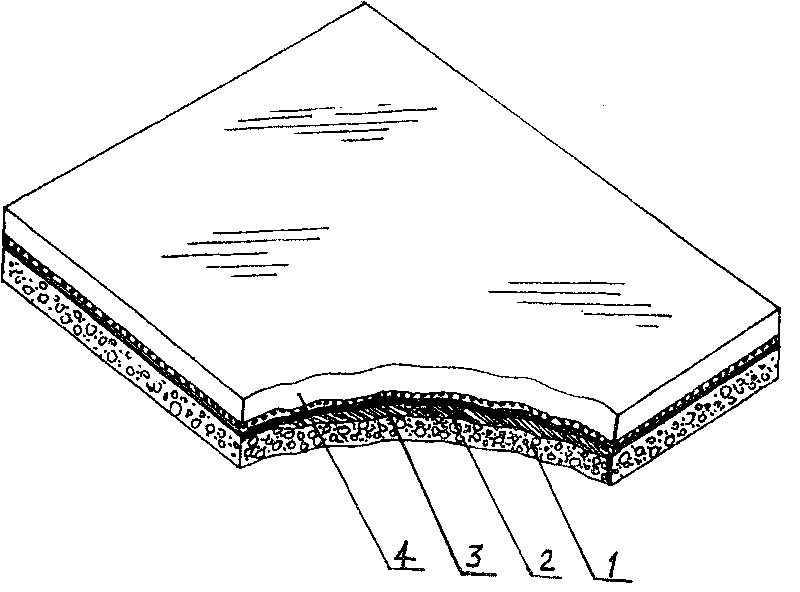

[0039] Such as figure 1 As shown, the glass color printing wall and floor tile is characterized in that it is composed of a glass layer 4, a color pattern layer 3, an adhesive layer 2 and a magnesium oxide lightweight foamed molded brick layer 1; the glass layer 4 is the surface layer, and the color pattern The layer 3 is printed on the glass layer 4, the adhesive layer 2 is coated on the color pattern layer 3, and the magnesium oxide lightweight foamed molded brick 1 is the bottom layer, which is directly stuck to the wall or the ground. The glass layer 4 is colorless and transparent flat glass or tempered glass.

[0040] The production method of the glass color-printed wall and floor tile is characterized in that it includes five production processes of glass treatment, offset printing of the color pattern layer, making magnesium oxide lightweight foam molded bricks, bonding and edging; the specific production steps are:

[0041] (1) Glass treatment:

[0042] Choose colorl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com