Molten salt tube-shell type steam generating device and method

A steam generating device, shell-and-tube technology, applied in the field of molten salt shell-and-tube steam generating device, can solve the problem that the heat storage function of molten salt working medium and molten salt tank is not fully utilized, and the structure of the serpentine heat-absorbing pipe body is complicated , Heat transfer process parameters are not easy to control and other problems, to achieve the effect of stable heat exchange and evaporation process, convenient for large-scale production, and beneficial to cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

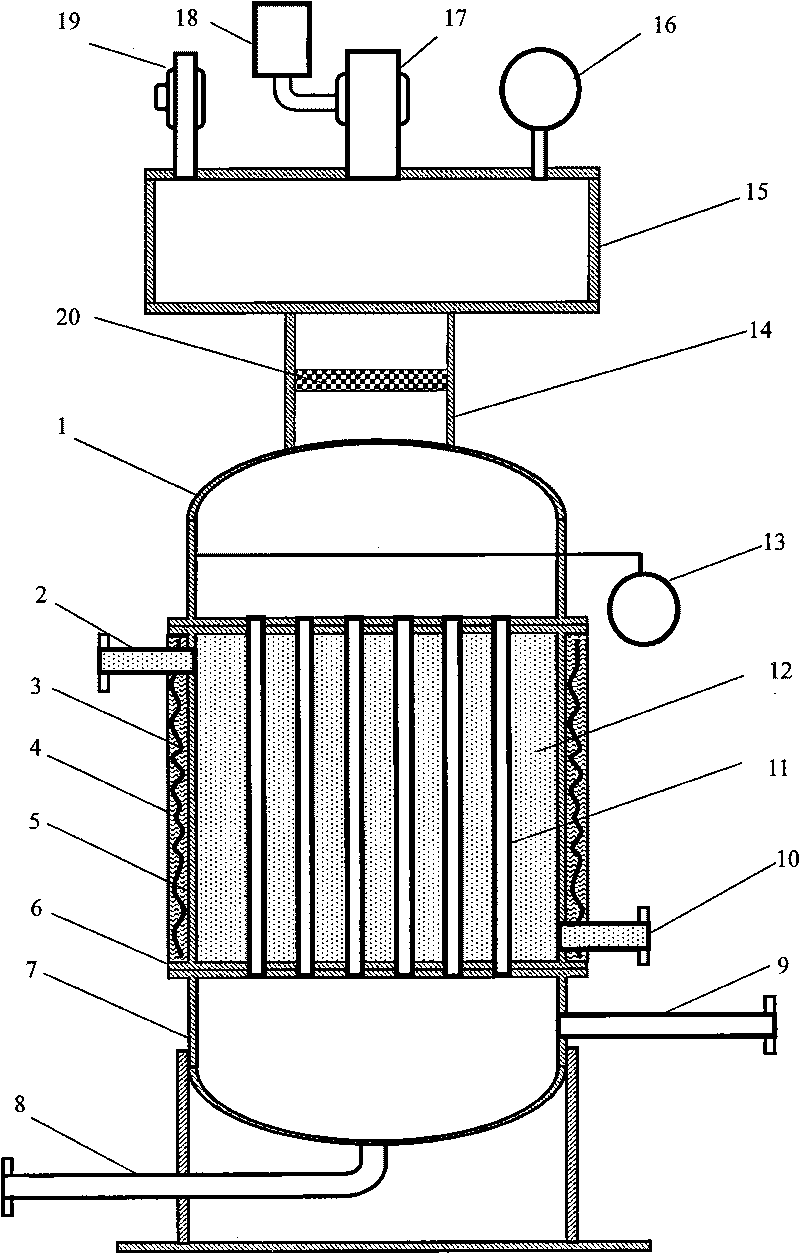

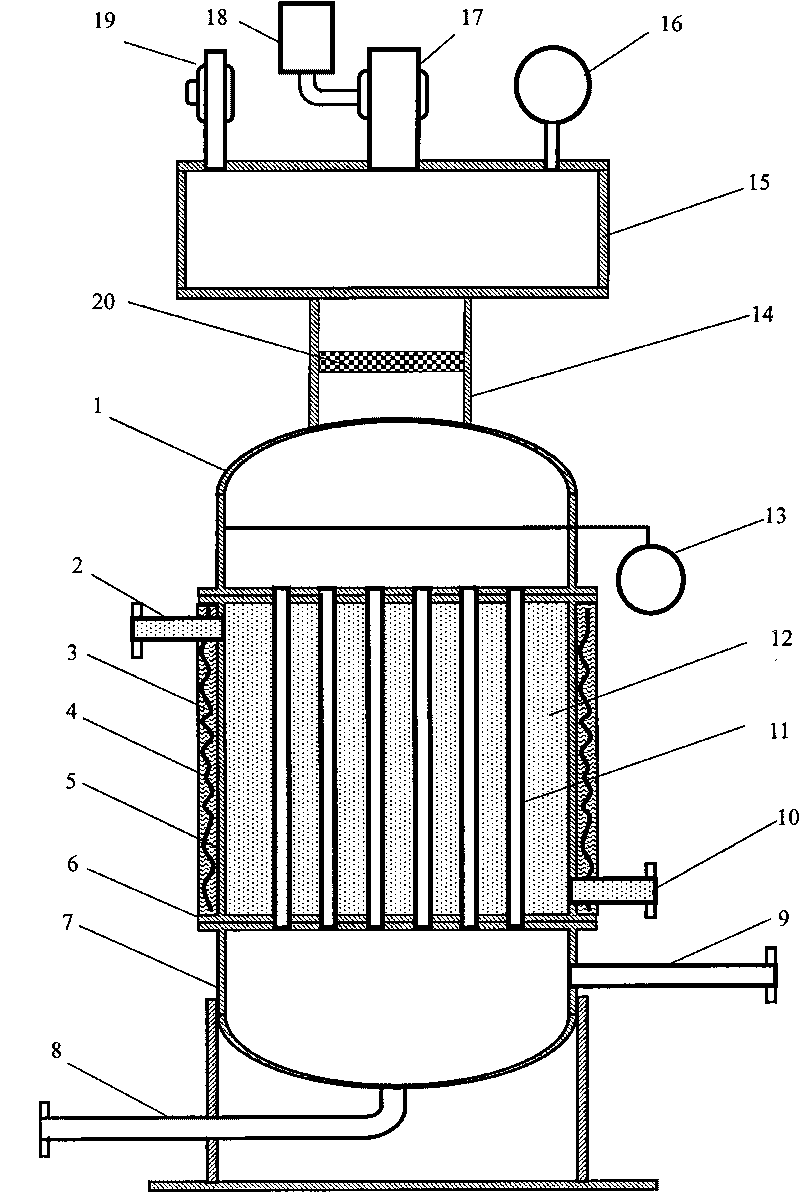

[0032] In this embodiment, a molten salt shell-and-tube steam generating device has a structure such as figure 1 As shown, it includes a shell-and-tube heat exchanger, a steam separation output assembly and a heating and heat preservation assembly. The steam separation output assembly is arranged on the top of the shell-and-tube heat exchanger, and the heating and insulation assembly is arranged on the outside of the container wall of the shell-and-tube heat exchanger; The shell-and-tube heat exchanger includes a top tube box 1, a tube body 5 and a bottom tube box 7 arranged sequentially from top to bottom. A tube bundle 11 is arranged inside the tube body 5, and the two ends of the tube bundle 11 pass through the tube sheet 6 and the tube body 5 respectively. Fixed connection, the gap between the tube bundles 11 in the pipe body 5 is filled with molten salt 12; the outer side of the pipe body 5 is provided with a molten salt inlet pipe 10 and a molten salt outlet pipe 2, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com