A biomass gasification combustion boiler system

A biomass and gasifier technology, applied in steam boilers, combustion equipment, combustible gas purification, etc., can solve the problems of high pollution, energy consumption, low combustion efficiency, etc., to reduce production costs, improve combustion efficiency, and increase heat energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

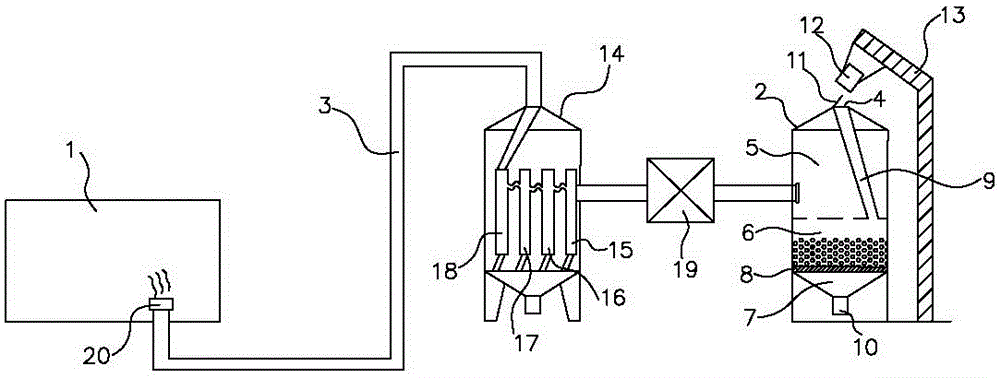

[0024] see figure 1 , a biomass gasification combustion boiler system, including a boiler 1 and a biomass gasification furnace 2 for providing gasification fuel for the boiler 1, the biomass gasification furnace 2 is connected to the boiler 1 through a gas pipeline 3, the The upper part of the biomass gasification furnace 2 is provided with a feed inlet 4, and the inside of the biomass gasification furnace 2 is a gas storage chamber 5, a reaction chamber 6, and an ash storage bucket 7 from top to bottom. A heating grate 8 is arranged between the ash hoppers 7, and the feed inlet 4 communicates with the reaction chamber 6 through a feed pipeline 9, and the gas storage chamber 5 and the reaction chamber 6 of the biomass gasification furnace 2 are separated from each other, Therefore, the gasification fuel stored in the gas storage chamber 5 can be continuously supplied to the boiler 1 for combustion. Even in the process of charging the biomass gasification furnace 2, the boiler ...

Embodiment 2

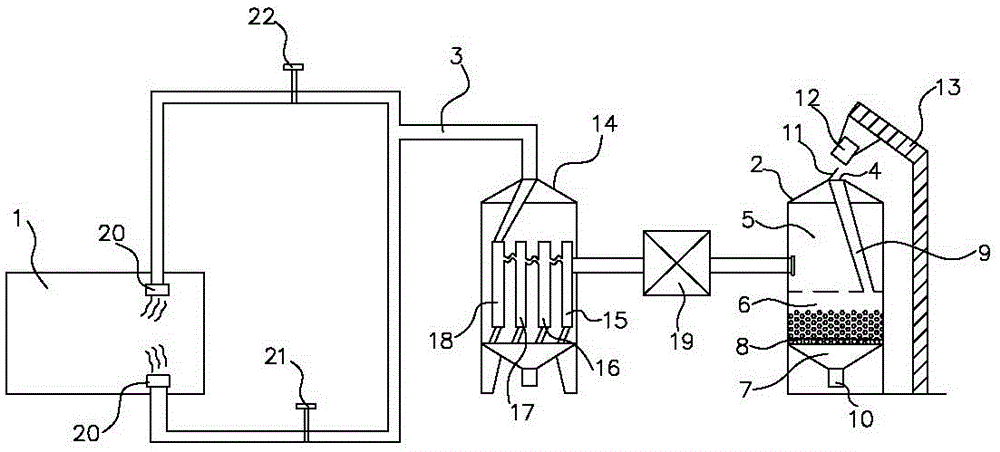

[0035] see figure 2The difference between this embodiment and Embodiment 1 is that: the gas pipeline 3 connected to the boiler 1 includes two paths, and the two gas pipelines 3 extend into the furnace from both sides of the boiler 1 respectively, and the two gas pipelines 3 respectively extend from The two sides of the boiler 1 extend into the furnace and burn, which can greatly improve the combustion heat production efficiency of the boiler 1. The two gas pipelines 3 are respectively provided with a first control valve 21 and a second control valve 22, which are input to the boiler 1 per unit time. The amount of gasified fuel in the furnace is controlled to better meet the needs of production.

[0036] For the technical features not explained in this embodiment, the explanations in Embodiment 1 are used, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com