Ceramic filled type neutron tube

A filling type and neutron tube technology, applied in the field of neutron tubes, can solve the problems of difficult processing and low yield, and achieve the effects of reducing discharge, increasing output, and ensuring collimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

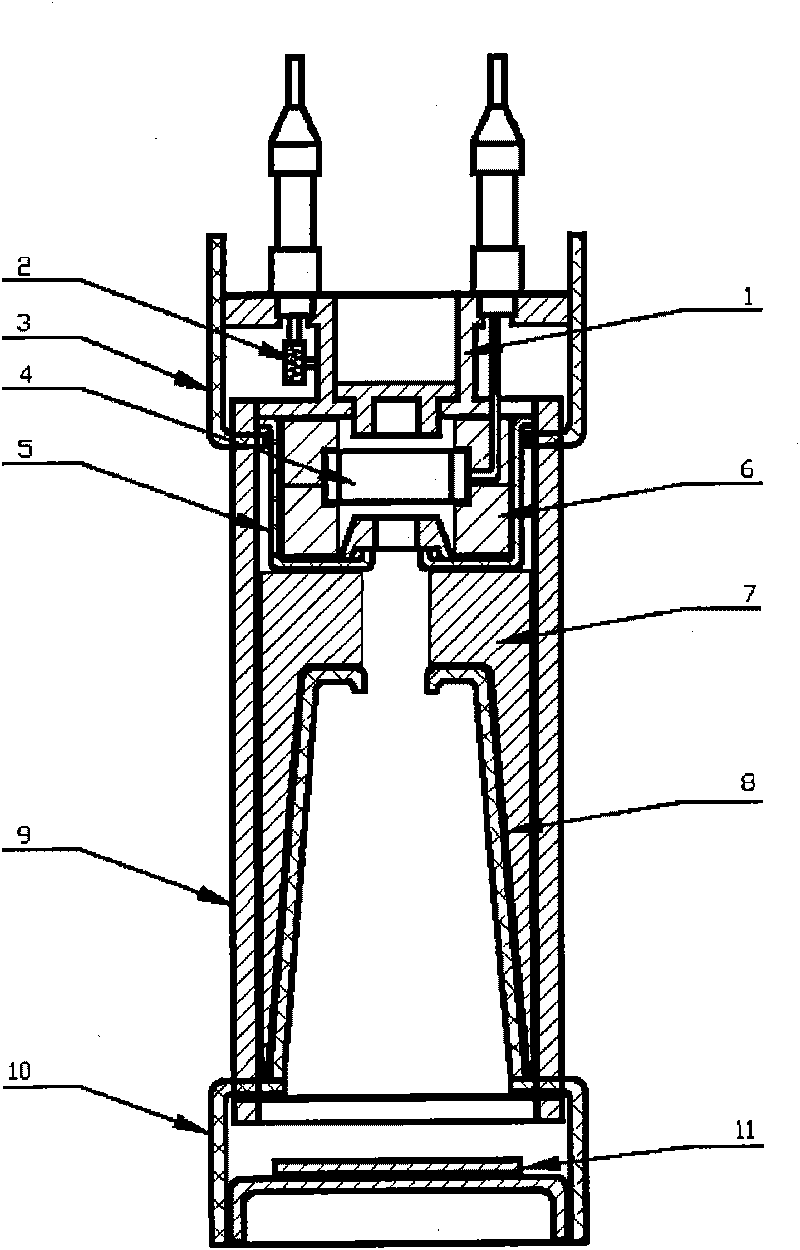

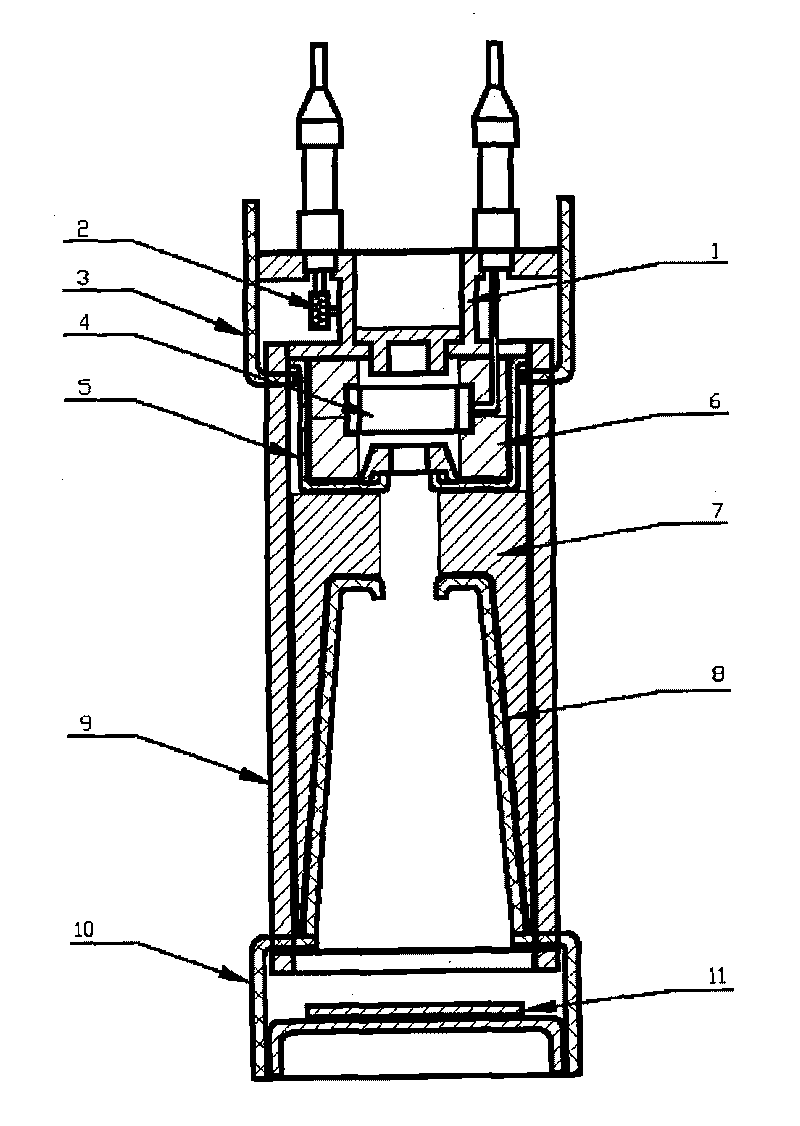

[0008] The neutron tube of the present invention is a circular axisymmetric structure, which seals the ion source, acceleration system, target and air pressure adjustment system in a ceramic tube to form an electric vacuum device with a simple and compact structure and easy use. The relationship with the location is shown in the attached figure. First, the copper head 1 and the target 11 are prepared and cleaned; then the upper cover 3, the ion source cover 5, the ceramic insulating ring 7, the acceleration cylinder 8, the lower cover 10 and the ceramic shell 9 are sealed together, and the ion source cover 5 and the ceramic insulating ring 7 placed between the acceleration cylinder 8, the inner side should ensure close contact with the ion source cover 5 and the acceleration cylinder 8, and the outer diameter is the same as the inner diameter of the ceramic shell 9. Between the ion source cover 5 and the acceleration cylinder 8 There is a center hole between them, the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com