Nasal meatus breathing tampon tube

A technology for ventilation tubes and nasal passages, which is applied in the field of clinical medical equipment and nasal passage ventilation packing tubes. It can solve the problems of increasing procedures and difficulty, complicated use process, etc., and achieves the effect of meeting clinical needs, being convenient to take out, and convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

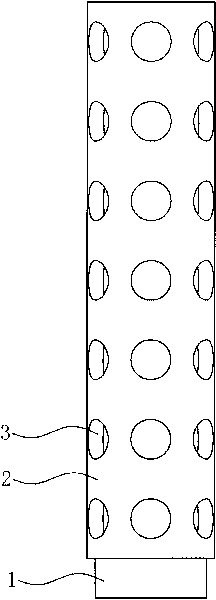

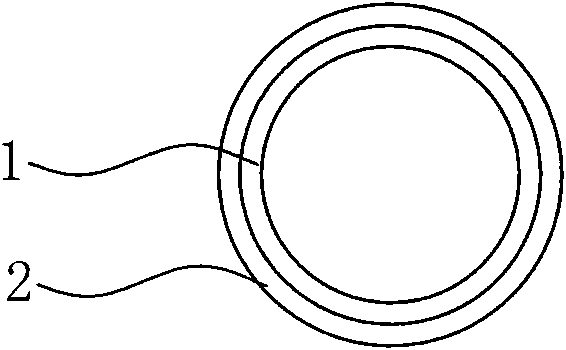

[0023] Embodiment one: see attached figure 1 , 2 As shown, a nasal airway packing tube includes a ventilation tube 1 and a hemostatic layer 2; the axial length of the ventilation tube 1 is 75 mm, the inner diameter is 8 mm, and the outer diameter is 10 mm. The ventilation tube 1 is made of medical elastic silicone rubber Made; the hemostatic layer 2 is coated on the outer surface of the ventilation tube 1, the thickness of the hemostatic layer 2 is 2 mm, and the axial length is 70 mm (therefore, there is a part of 5 mm at one end of the ventilation tube that is not covered, so that the nasal passage can be closed after use. ventilation packing tube), the hemostatic layer 2 is made of gelatin sponge; the wall of the nasal passage ventilation packing tube is provided with a number of through holes 3, the distance between adjacent through holes 3 is 10 mm, and the aperture is 5 mm.

[0024] The above-mentioned nasal airway stuffing tube is inserted into the total nasal passage o...

Embodiment 2

[0025] Embodiment two: see attached figure 1 , 2 Shown, a kind of nasal airway stuffing tube, comprises ventilation tube 1, also comprises a hemostatic layer 2; The axial length of ventilation tube 1 is 25mm, and inner diameter is 3mm, and outer diameter is 5mm, and ventilation tube 1 is made of medical elastic silicon rubber Made; the hemostatic layer 2 is coated on the outer surface of the ventilation tube 1, the thickness of the hemostatic layer 2 is 3mm, and the axial length is 20mm (therefore, there is a part of 5mm at one end of the ventilation tube that is not covered, so that the nasal passage can be closed after use. ventilation packing tube), the hemostatic layer 2 is made of expanded sponge; the wall of the nasal passage ventilation packing tube is provided with a number of through holes 3, the distance between adjacent through holes 3 is 10mm, and the aperture is 3mm.

[0026] The above-mentioned nasal airway stuffing tube is inserted into the total nasal passage ...

Embodiment 3

[0027] Embodiment three: see attached figure 1 , 2 Shown, a kind of nasal airway packing tube, comprises ventilation tube 1, also includes a hemostatic layer 2; Made; the hemostatic layer 2 is coated on the outer surface of the ventilation tube 1, the thickness of the hemostatic layer 2 is 2mm, and the axial length is 45mm (therefore one end of the ventilation tube has a part of 5mm that is not covered, so that the nasal passage can be closed after use. ventilation packing tube), the hemostatic layer 2 is made of expanded sponge; the wall of the nasal passage ventilation packing tube is provided with a number of through holes 3, the distance between adjacent through holes 3 is 10mm, and the aperture is 5mm.

[0028] The above-mentioned nasal passage stuffing tube is inserted into the total nasal passage of the patient, the patient's nasal cavity can maintain normal ventilation, and at the same time, wound bleeding can be prevented, and infection can be prevented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com