Thin-wall high temperature alloy tubing simulation extrusion device

A high-temperature alloy and extrusion device technology, which is applied in the direction of metal extrusion, metal extrusion die, and the container of the metal to be extruded, can solve the problems of high experimental cost, manpower and material resources, and long preparation period, and achieve universality Good, short time-consuming, high material utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

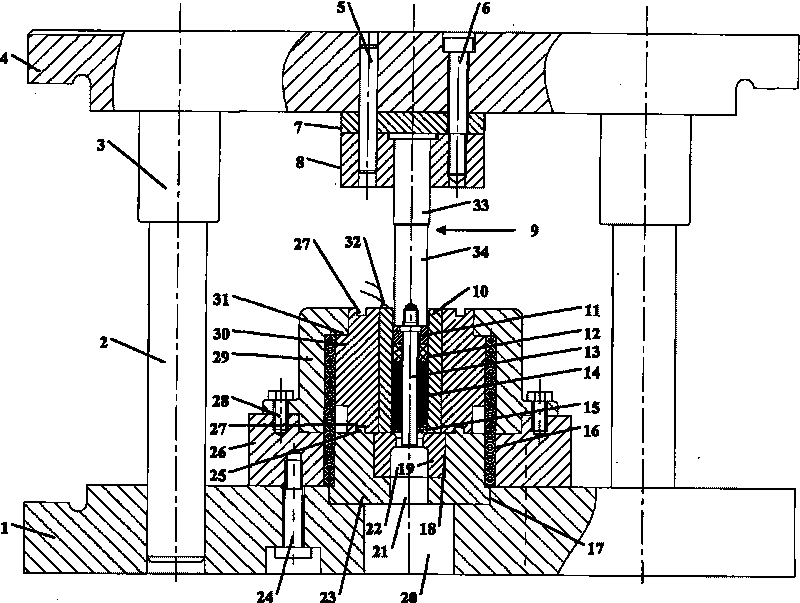

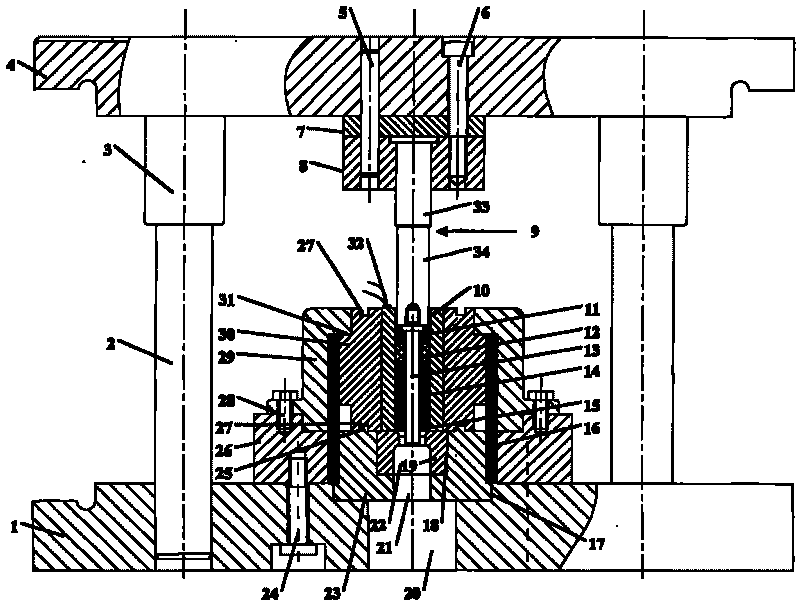

[0028] The invention is a thin-wall superalloy pipe simulation extrusion device, such as figure 1 As shown, the mold for simulating hot extrusion of pipes is installed on a standard mold base with a guiding device. The guiding device includes an upper die base 4, a lower die base 1, a guide post 2 and a guide sleeve 3. One end of the guide sleeve 3 is connected to the upper die base. The base 4 is connected, the guide post 2 is connected with the lower mold base 1, the other end of the guide post 2 is sleeved in the guide sleeve 3, and can move up and down along the guide sleeve 3, and the mold for simulating hot extrusion of pipes includes an extrusion shaft 9, an extrusion Needle 13, extrusion pad 11, positioning frame 29, extrusion barrel lining 10, extrusion barrel outer lining 30, die pad 23, pad 26 and extrusion die 19.

[0029] The extrusion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com