Photoelectrically controlled industrial weighing device

A photoelectric control and weighing device technology, applied in the direction of measuring devices, packaging automatic control, automatic feeding/discharging weighing equipment, etc., can solve the problem that weighing is not easy to be accurate, industrial automatic production cannot be realized, waste of labor, etc. problems, to achieve the effect of moderate equipment cost, safe and reliable use, and flexible operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

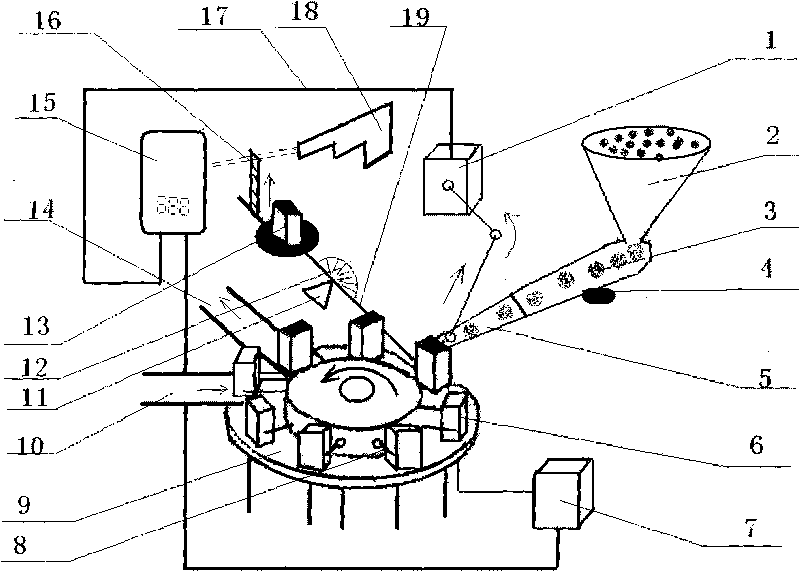

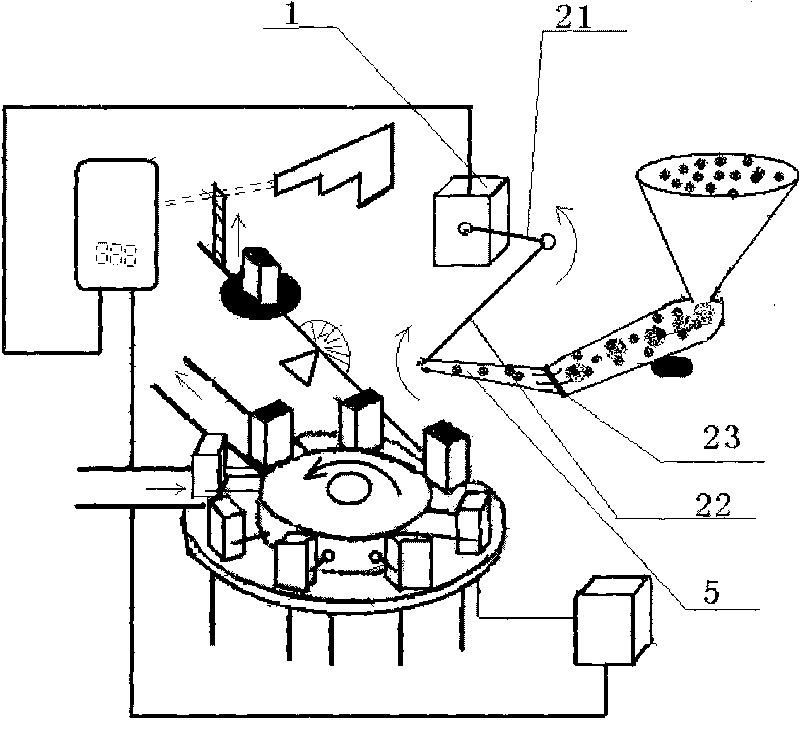

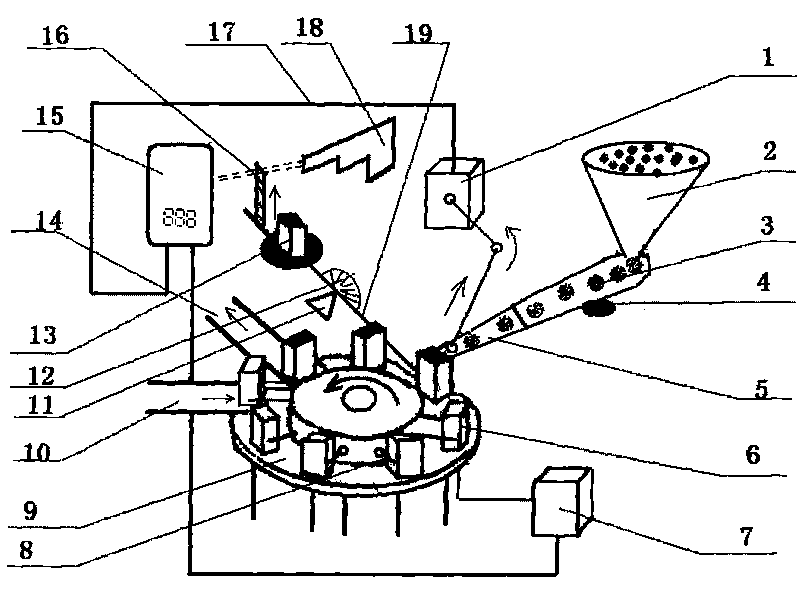

[0017] Such as figure 1 As shown, the present invention is mainly for the purpose of weighing a batch of bulk goods. The bulk products are placed in the hopper 2 in advance, and the empty box is put into the box inlet channel 10. When the empty box is automatically transferred to the bottom of the blanking plate 5 , the vibrator 4 starts to vibrate, so that the goods 3 on the blanking plate 5 flow into the empty box continuously, at this moment the weighing system starts, and the sample 13 has been placed on the other side of the lever (so that the sample and to be weighed Heavy goods are the same weight), when the goods are full, the lever 19 is balanced, so that the set scale 16 just blocks the light emitted by the luminous gun 18, and the photoelectric sensor 15 sends a signal, and the photoelectric sensor 15 will "notify" to promote The controller 1 stops loading, and at the same time "notifies" the vibrator 4 to stop vibrating, and the box full of goods is sent to the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com