High strength and high toughness ship plate steel with thick specification and production method thereof

A high-strength, high-toughness, production method technology, applied in the direction of temperature control, etc., can solve the problems of uneven performance along the thickness direction, harsh requirements for rolling mill equipment, uneven structure, etc., and achieve good structure uniformity, optimized speed range, and homogenization organization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

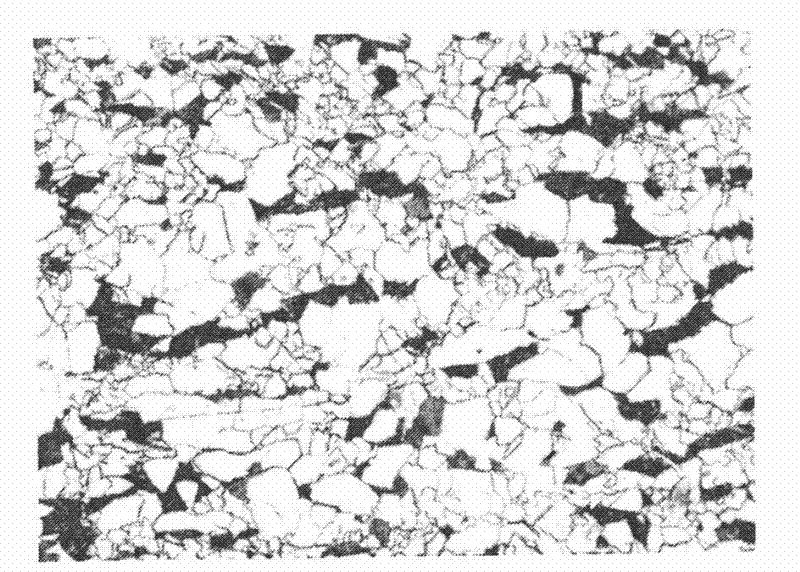

[0024] This embodiment is a thick-gauge, high-strength, high-toughness ship plate steel and its production method. The components are calculated by weight percentage: C 0.1133%, Si 0.312%, Mn 1.4812%, Ni 0.228%, Cu 0.0337%, Mo 0.005%, Nb 0.028%, Ti 0.004%, P 0.0083%, S 0.0019%, Cr 0.0734%, V 0.0436%, the balance is Fe and unavoidable inclusions, and the billet with a thickness of 150mm is continuously cast.

[0025] The slabs are stacked and cooled for more than 72 hours, and the slabs are heated at 1200°C, the temperature uniformity is less than 20°C, the heating rate is 12-14min / cm, and after 30-50min of heat preservation, high-pressure water dephosphorization is carried out, and two-stage controlled rolling is carried out. The finish rolling temperature in the recrystallization zone is 1060°C, and the deformation rate is 3s -1 , The amount of deformation in 4 passes is 60%, and the thickness of the intermediate billet is controlled at 90mm. The rolling start temperature in...

Embodiment 2

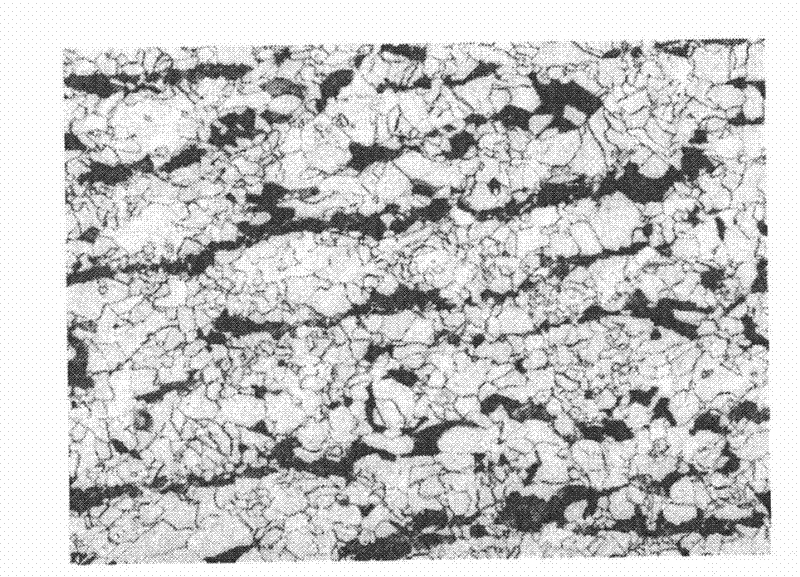

[0031] This embodiment is a kind of thick-gauge, high-strength and high-toughness ship plate steel and its production method. The components are calculated by weight percentage, C 0.1247%, Si 0.309%, Mn 1.49%, Ni 0.29%, Cu 0.0385%, Mo 0.0069%, Nb 0.0332%, Ti 0.008%, P 0.0084%, S 0.0011%, Cr 0.0619%, V 0.049%, the balance is Fe and unavoidable inclusions, and the billet with a thickness of 150mm is continuously cast.

[0032] The slabs are stacked and cooled for more than 72 hours, the temperature of the slab soaking section is 1257°C, the temperature uniformity is less than 20°C, the heating rate is 12-14min / cm, and after 30-50min of heat preservation, high-pressure water dephosphorization is carried out, and two-stage controlled rolling is carried out. The rolling start temperature in the recrystallization zone is 1075°C, and the deformation rate is 3s -1 , The amount of deformation in 5 passes is 65%, and the thickness of the intermediate billet is controlled at 90mm. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com