Rodless oil extraction system driven by underground rotation motor

A rotary motor and rodless oil production technology, which is applied in the direction of electric components, production fluids, electrical components, etc., can solve problems such as reciprocating and partial wear of sucker rods and oil pipes, increased crude oil production costs, and increased maintenance workload. The problem of eccentric wear of pipe rods, the effect of reducing operation and maintenance costs and labor intensity of workers, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

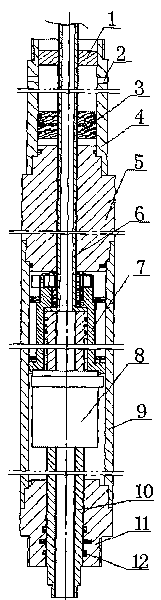

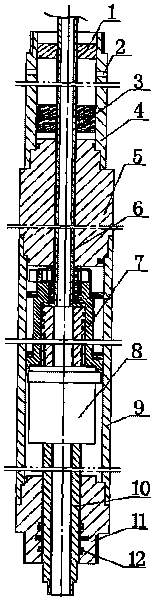

[0013] Embodiment 1: Taking a rodless oil production system driven by a downhole rotating motor with an outer diameter of 108mm and a length of 6.7m as an example, the present invention will be further described in detail.

[0014] refer to figure 1 . The rodless oil production system driven by the downhole rotating motor of the present invention is mainly composed of a pressure balance device, a three-phase asynchronous rotating motor 5, a mechanical conversion mechanism, a lower cylinder 9 and a lower plug 11.

[0015] The pressure balance device includes an upper spacer ring 1, a breathing hole 2, a balance piston 3 and an upper cylinder 4. The outer diameter of the upper cylinder 1 is 108 mm, the inner diameter is 98 mm, and the top of the upper cylinder 4 has an external thread of M108×1.5. The hoop (one end is M108×1.5 internal thread and the other end is 27 / 8TBG internal thread) is connected with the 27 / 8 flat oil pipe. There are two breathing holes with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com