Low-heat expansion quartz gauge rod as well as demarcating method and application thereof

A low thermal expansion, quartz technology, used in measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of fitting error, high price of high-precision gauge blocks, affecting the accuracy of gauge blocks, etc., to achieve no fitting error, The effect of a small number of points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

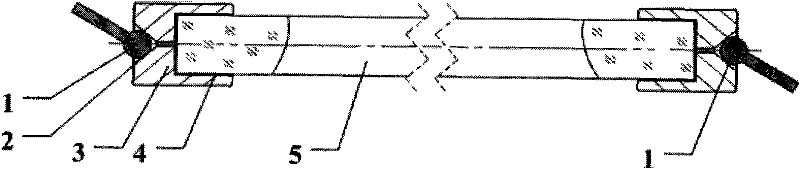

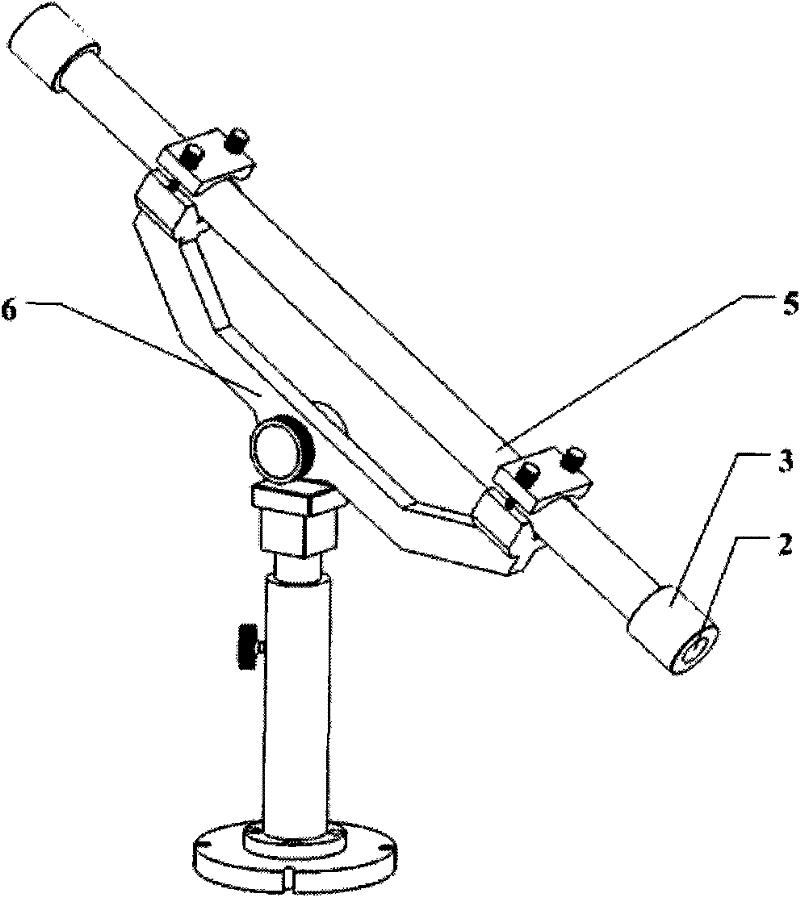

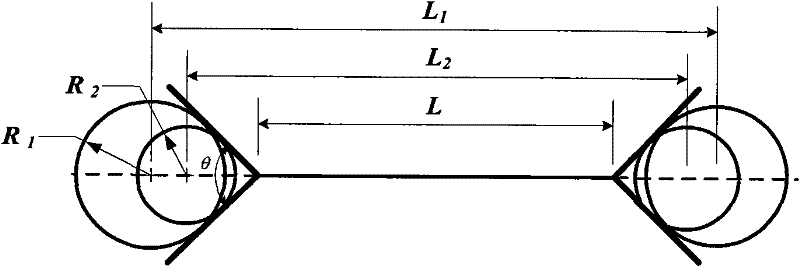

[0030] see figure 1 , figure 2 , the quartz rod 5 with low thermal expansion coefficient is set as the main body, and the two ends are covered with metal sleeves 3. The end faces of the metal sleeves at both ends each have a cone dimple 2, and the cone angle and depth of the cone dimples 2 on the two ends are the same. The nest centerlines coincide. In a specific implementation, the cone angle θ of the cone dimple is set at 90°-120°.

[0031] The cone socket 2 is used for positioning the probe 1 of the measuring machine to be calibrated for the articulated coordinate measuring machine, and the surface needs to be carefully ground and processed to make it have a better conicity.

[0032] The metal sleeve 3 and the quartz rod 5 are bonded by glue, and glue with a low coefficient of thermal expansion and good thermal stability is selected to form a low thermal expansion glue layer 4 to realize bonding and fixing. When bonding the metal sleeve 3, take one of the sleeve end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com