Base liquid of synthetic base drilling fluid

A drilling fluid and synthesis-based technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of low drilling fluid viscosity, formation fracture, and single performance, and achieve good biodegradability and wide acid-base conditions. , the effect of excellent surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

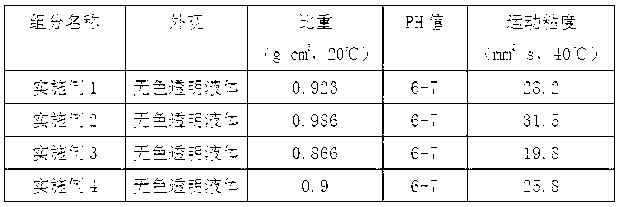

Embodiment 1

[0013] According to the weight ratio relationship, take 1 part of limonene, 0.5 parts of dipentene, 5 parts of ethylene glycol monobutyl ether, 1 part of alkyl glycoside, 2 parts of alcohol ether carboxylate, 10 parts of white oil and 1.25 parts of simethicone , the above raw materials are mixed and stirred to obtain the base liquid.

Embodiment 2

[0015] According to the weight ratio relationship, take 1 part of limonene, 0.75 parts of dipentene, 3 parts of ethylene glycol monobutyl ether, 5 parts of alkyl glycosides, 1.5 parts of alcohol ether carboxylate, 1 part of white oil and 3 parts of simethicone , the above raw materials are mixed and stirred to obtain the base liquid.

Embodiment 3

[0017] According to the weight ratio relationship, take 1 part of limonene, 1 part of dipentene, 2.5 parts of ethylene glycol monobutyl ether, 10 parts of alkyl glycoside, 3 parts of alcohol ether carboxylate, 5 parts of white oil and 1.5 parts of simethicone , the above raw materials are mixed and stirred to obtain the base liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com