Bimetal liquid-liquid composite packer and production method thereof

A manufacturing method and bimetal technology, applied in the field of ramming picks, can solve the problems of high production cost, short service life of ramming picks, etc., and achieve the effects of long service life, not easy to fall off, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

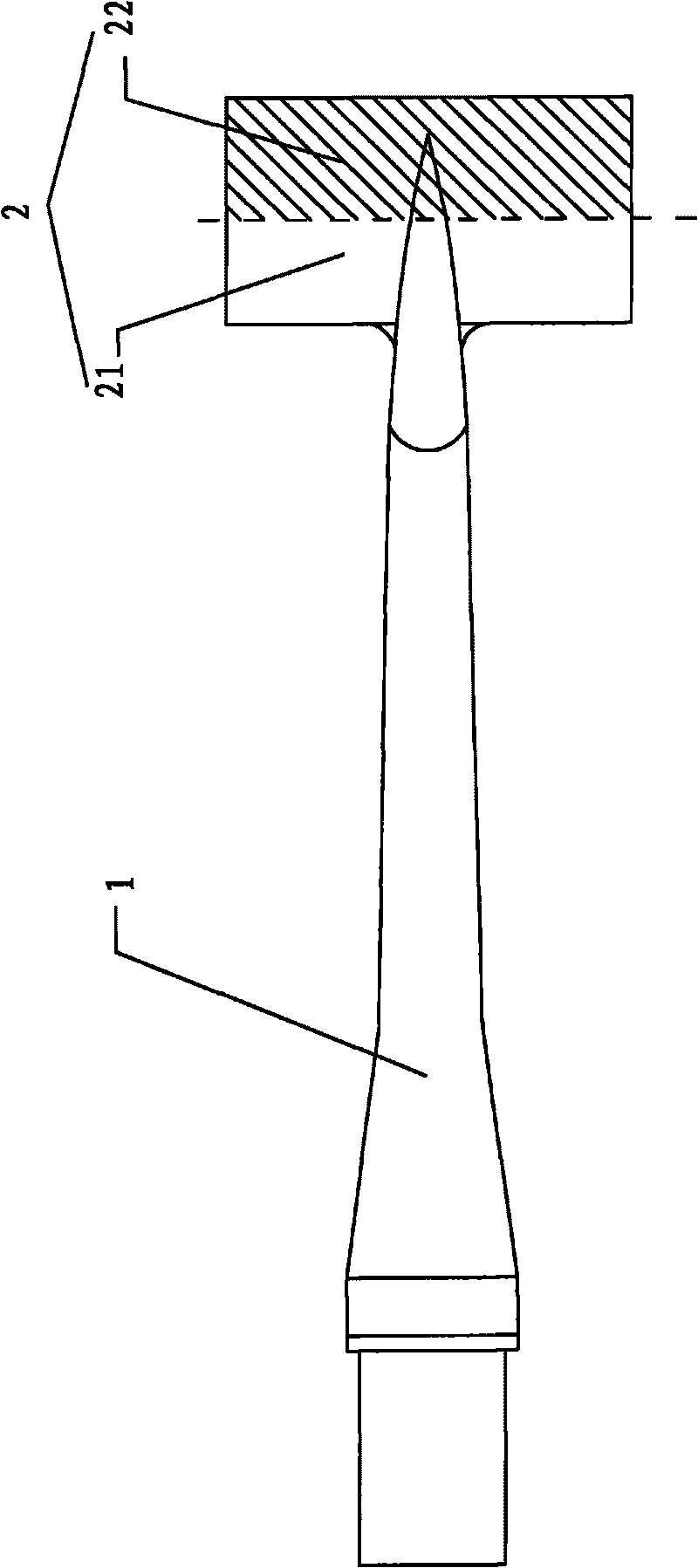

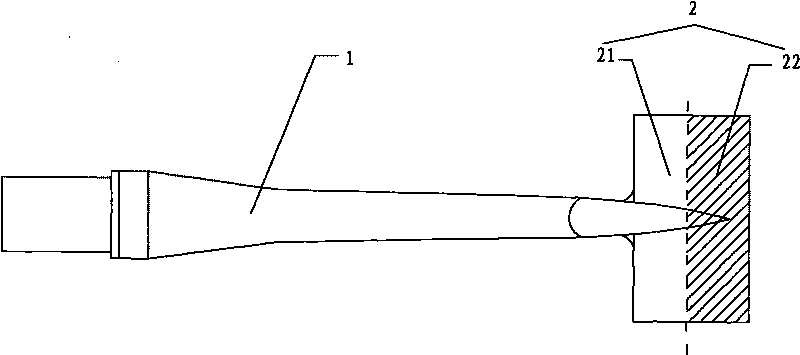

[0026] see figure 1 As shown, a bimetallic liquid-liquid composite pounding pick is composed of a pick body 1 and a pick palm 2. The upper end of the pick body 1 and the pick palm 2 accounts for 1 / 2 of the whole pick palm 1. The non-working surface part 21 is cast from 35CrMo alloy. Its carbon content is 0.3%. The lower end of the pick palm 2 accounts for 1 / 2 of the overall working surface part 22 of the pick palm 2. It is cast from a high-chromium-molybdenum-nickel-tungsten alloy melt. 25% chromium, 0.5% molybdenum, 1% nickel, 0.5% tungsten, 3.5% carbon, and the balance is iron. The working face part 22 of the pick palm is compounded on the non-working face part 21 of the pick palm.

[0027] The manufacturing method of the present embodiment is as follows:

[0028] Two smelting electric furnaces are used to smelt low-chromium ordinary steel and high-chromium-molybdenum-nickel-tungsten alloy respectively. First, pour the molten 35CrMo alloy with a temperature of 1660°C into...

Embodiment 2

[0030] see figure 1 As shown, a bimetallic liquid-liquid composite pounding pick is composed of a pick body 1 and a pick palm 2. The upper end of the pick body 1 and the pick palm 2 accounts for 2 / 3 of the whole pick palm 1. The non-working surface part 21 is cast from 35CrMo alloy. Its carbon content is 0.35%. The lower end of the pick palm 2 accounts for 1 / 3 of the overall working surface part 22 of the pick palm 2. It is cast from a high-chromium-molybdenum-nickel-tungsten alloy melt. 30% chromium, 1% molybdenum, 0.6% nickel, 1% tungsten, 3.8% carbon, and the balance is iron. The working face part 22 of the pick palm is compounded on the non-working face part 21 of the pick palm.

[0031] The manufacturing method of the present embodiment is as follows:

[0032] Two smelting electric furnaces are used to smelt low-chromium ordinary steel and high-chromium-molybdenum-nickel-tungsten alloy respectively. First, pour the molten 35CrMo alloy with a temperature of 1665°C into ...

Embodiment 3

[0034] see figure 1 As shown, a bimetallic liquid-liquid composite pounding pick is composed of a pick body 1 and a pick palm 2. The upper end of the pick body 1 and the pick palm 2 accounts for 3 / 5 of the whole pick palm 1. The non-working surface part 21 is made of No. 45 steel It is casted, and its carbon content is 0.42%. The lower end of the pick palm 2 accounts for 2 / 5 of the overall working surface part 22 of the pick palm 2. It is cast from a high-chromium-molybdenum-nickel-tungsten alloy melt. It contains 35% chromium, 1.5% molybdenum, 1.2% nickel, 1.6% tungsten, 4% carbon, and the balance is iron. The working face part 22 of the pick palm is compounded on the non-working face part 21 of the pick palm.

[0035] The manufacturing method of the present embodiment is as follows:

[0036] Two smelting electric furnaces are used to smelt low-chromium ordinary steel and high-chromium-molybdenum-nickel-tungsten alloy respectively. Firstly, the No. 45 molten steel with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com