Waterproof paint composition of outer wall polymer cement

A waterproof coating and polymer technology, which is applied in the field of polymer cement waterproof coating composition for exterior walls, can solve the problems of decreased softening strength, limited elongation rate, and decreased elongation rate, so as to improve stability, prolong service life, reduce coating The effect of the degree of membrane swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare 60 parts of 20% gelatin aqueous solution at 50°C, add 0.5 parts of water reducer, 0.5 parts of polyethylene glycol cadmium chloride, add 30 parts of 600 mesh barite powder under stirring, add 10 parts of 800 mesh Lide powder, then add 1 part of 5-methyl-7-hydroxy-1.3.4 triazindolizine, and stir for 30 minutes; then add 3 parts of 2.4-dichloro-6-hydroxy-s-triazine sodium salt (alias hard film Agent A), and then stirred for 10 minutes to obtain aseptic barium-zinc latex.

[0034] The composition of exterior wall polymer cement waterproof coating composition:

[0035] 100 parts of elastic acrylic emulsion, 120 parts of white cement, 20 parts of titanium dioxide, 25 parts of heavy calcium carbonate, 2 parts of dibutyl phthalate, 2 parts of dipropylene glycol methyl ether, 0.5 parts of sodium aluminate, 2 parts of water reducer , 2 parts of defoamer, 80 parts of sterile barium zinc latex

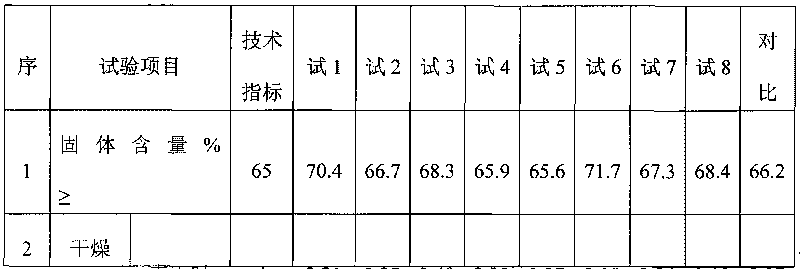

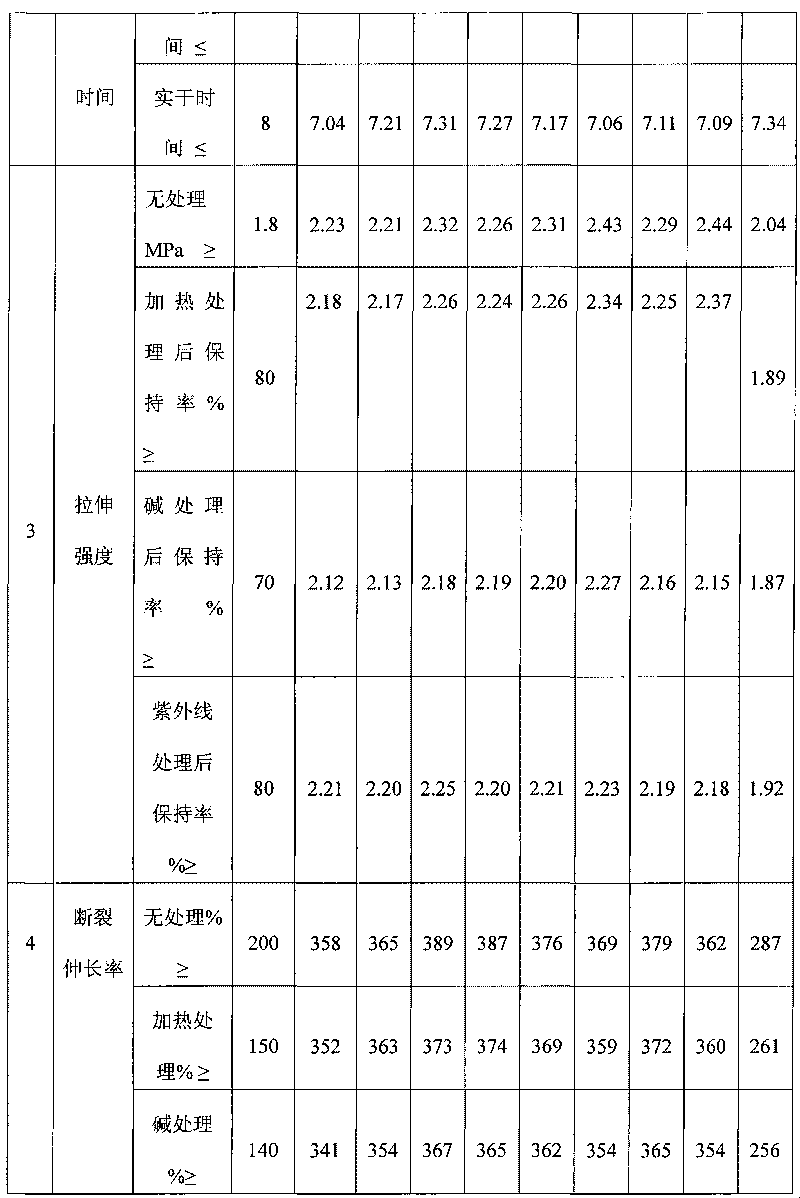

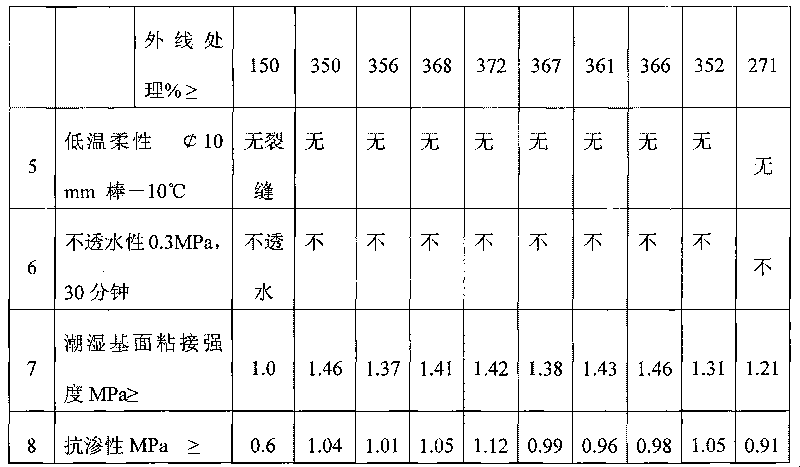

[0036] Stir and mix each component to obtain the product, and the test resul...

Embodiment 2

[0038] At 60°C, prepare 60 parts of 15% gelatin aqueous solution, add 1 part of water reducing agent, 1.5 parts of polyethylene glycol cadmium chloride, add 30 parts of 700 mesh barite powder under stirring, add 600 mesh of 10 parts of Lide powder, then add 3 parts of 5-methyl-7-hydroxy-1.3.4 triazindolizine, and stir for 40 minutes; then add 1 part of 2.4-dichloro-6-hydroxy-s-triazine sodium salt (alias Agent A), and then stirred for 20 minutes to obtain sterile barium-zinc latex.

[0039] The composition of exterior wall polymer cement waterproof coating composition:

[0040] 110 parts of elastic acrylic emulsion, 110 parts of white cement, 30 parts of titanium dioxide, 20 parts of heavy calcium carbonate, 3 parts of dibutyl phthalate, 3 parts of dipropylene glycol methyl ether, 1 part of sodium aluminate, 3 parts of water reducer , 3 parts of defoamer, 70 parts of sterile barium zinc latex. Stir and mix each component to obtain the product, and the test results are shown ...

Embodiment 3

[0042] Prepare 60 parts of 18% gelatin aqueous solution at 70°C, add 1.5 parts of water reducer, 1 part of polyethylene glycol cadmium chloride, add 30 parts of 800 mesh barite powder under stirring, add 10 parts of 700 mesh Lide powder, then add 2 parts of 5-methyl-7-hydroxy-1.3.4 triazindolizine, and stir for 50 minutes; then add 2 parts of 2.4-dichloro-6-hydroxy-s-triazine sodium salt (alias Agent A), and then stirred for 30 minutes to obtain sterile barium-zinc latex.

[0043] The composition of exterior wall polymer cement waterproof coating composition:

[0044] 120 parts of elastic acrylic emulsion, 100 parts of white cement, 40 parts of titanium dioxide, 30 parts of heavy calcium carbonate, 4 parts of dibutyl phthalate, 4 parts of dipropylene glycol methyl ether, 1.5 parts of sodium aluminate, 4 parts of water reducer , 4 parts of defoamer, 60 parts of sterile barium zinc latex. Stir and mix each component to obtain the product, and the test results are shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com