Light refractory deck covering

A deck dressing and fire-resistant technology, applied in the field of deck dressing, can solve the problems of long construction period, inconvenient construction, and multiple layers of dressing, so as to avoid construction inconvenience and unsafe factors, reduce the arrangement and coordination of processes, and reduce the weight of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

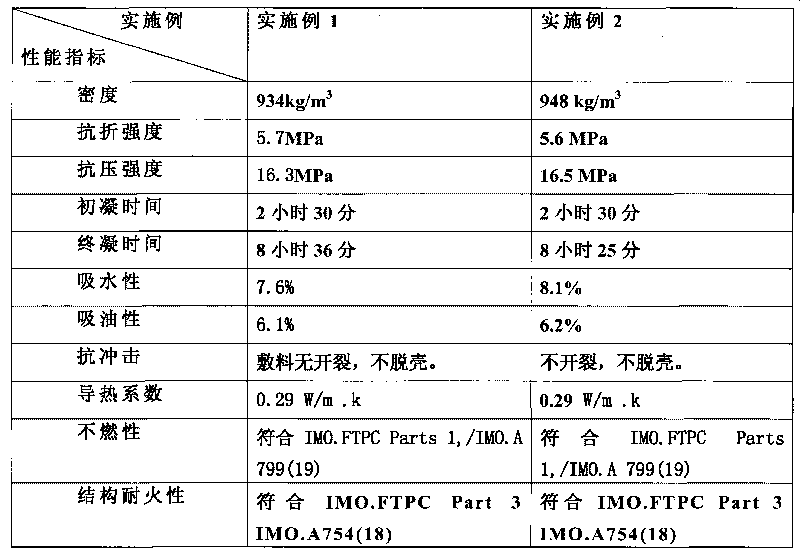

Embodiment 1

[0017] The lightweight fire resistant deck covering according to this embodiment includes an inorganic binder and a covering body. Wherein the inorganic binder is composed of 45wt% carbon silicon alumina and 55wt% sodium silicate. The dressing main body is composed of 32wt% filler, 52wt% coagulant and 14wt% accelerator liquid.

[0018] In this example, the filling material is made of 85% shale pottery sand, 6.5% vermiculite and 8.5% steel fiber. Among them, the particle size of shale pottery sand is 3-5mm, and the density is 500kg / m 3 About; the particle size of vermiculite is 2~3mm; the length of steel fiber is 28~32mm, and the tensile strength is greater than or equal to 600N / mm 2 , the radial twist is greater than or equal to 20 degrees. The coagulant is made by mixing 90wt% of 42.5 grade Portland cement, 5% of perlite powder and 5% of silicon powder; the accelerator liquid is composed of 3% of water reducer sodium naphthalenesulfonate formaldehyde condensate, 4% of phosp...

Embodiment 2

[0021] The lightweight fire resistant deck covering according to this embodiment includes an inorganic binder and a covering body. Wherein the inorganic binder is composed of 43.5wt% carbon silicon alumina and 56.5wt% sodium silicate. The dressing main body is composed of 35wt% filler, 52wt% coagulant and 13wt% accelerator liquid.

[0022] In this example, the coagulant and the accelerating liquid are the same as in the examples. The filling material is made of 87.5% shale pottery sand, 6% vermiculite and 6.5% steel fiber. Among them, the particle size of shale pottery sand is 3-5mm, and the density is 500kg / m 3 About; the particle size of vermiculite is 2~3mm; the length of steel fiber is 28~32mm, and the tensile strength is greater than or equal to 600N / mm 2 , the radial twist is greater than or equal to 20 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com