Method for preparing ethanol by using fresh potatoes

A potato and ethanol technology, applied in the field of ethanol production, can solve the problems of not introducing ethanol technology and large planting area, and achieve the effect of abundant raw materials, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

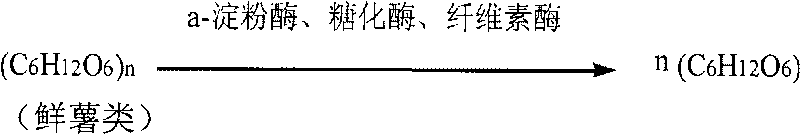

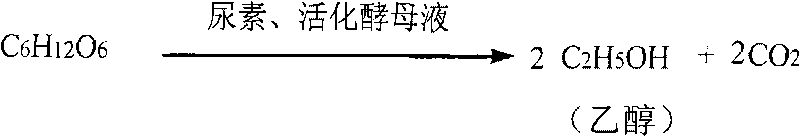

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the method for making ethanol with fresh potatoes, is prepared according to the following steps (preparation by weight):

[0015] Step 1: Grind 100 servings of fresh sweet potatoes into a paste;

[0016] Step 2: Add 30 parts of water to the above paste, heat up to 70°C while stirring, add 5000u / kg fresh potato a-amylase, keep the temperature at 70°C, liquefy for 30 minutes, and cool to 30°C;

[0017] Step 3: Add 6000u / kg fresh sweet potato glucoamylase, 4000u / kg fresh sweet potato cellulase, 1.0g / kg fresh sweet potato urea, and 30ml / kg fresh sweet potato activation to the liquid cooled to 30°C Yeast liquid, kept at 30°C, fermented for 6 days;

[0018] The fourth step: filter the above-mentioned fermentation liquid, use the filter residue as feed directly, then distill the filtrate, the temperature is controlled at 80°C, the effluent is ethanol, and the remaining waste water is used to clean fresh potatoes;

Embodiment 2

[0019] Embodiment 2: the method for making ethanol with fresh potatoes, prepared according to the following steps (preparation by weight):

[0020] Step 1: Grind 100 servings of fresh potatoes into a paste;

[0021] Step 2: Add 45 parts of water to the above paste, heat up to 78°C while stirring, add 5000u / kg fresh potato a-amylase, keep the temperature at 78°C, liquefy for 30 minutes, and cool to 32°C;

[0022] Step 3: Add 6000u / kg fresh potato glucoamylase, 4000u / kg fresh potato cellulase, 1.0g / kg fresh potato urea, 30ml / kg fresh potato urea to the liquid cooled to 32°C. The activated yeast solution of fresh potatoes is kept at 32°C and fermented for 6 days;

[0023] The fourth step: filter the above-mentioned fermentation liquid, use the filter residue as feed directly, then distill the filtrate, the temperature is controlled at 85°C, the effluent is ethanol, and the remaining waste water is used for cleaning fresh potatoes;

Embodiment 3

[0024] Embodiment 3: the method for making ethanol with fresh potatoes, prepared according to the following steps (preparation by weight):

[0025] Step 1: Grind 100 servings of fresh sweet potatoes into a paste;

[0026] Step 2: Add 50 parts of water to the above paste, heat up to 80°C while stirring, add 5000u / kg fresh potato a-amylase, keep liquefaction at 80°C for 30min, and cool to 35°C;

[0027] Step 3: Add 6000u / kg fresh sweet potato glucoamylase, 4000u / kg fresh sweet potato cellulase, 1.0g / kg fresh sweet potato urea, and 30ml / kg fresh sweet potato activated yeast to the above liquid cooled to 35°C liquid, the temperature was kept at 35°C, and the fermentation was done for 6 days;

[0028] The fourth step: filter the above-mentioned fermentation liquid, use the filter residue as feed directly, then distill the filtrate, the temperature is controlled at 100°C, the effluent is ethanol, and the remaining waste water is used to clean fresh potatoes;

[0029] The fresh pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com