Heating furnace for creep and rupture life tester

A technology of endurance test and heating furnace, which is applied in the field of endurance strength testing machine heating furnace and creep, and can solve the problems that cannot meet the test requirements and cannot well meet the requirements of large-scale tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

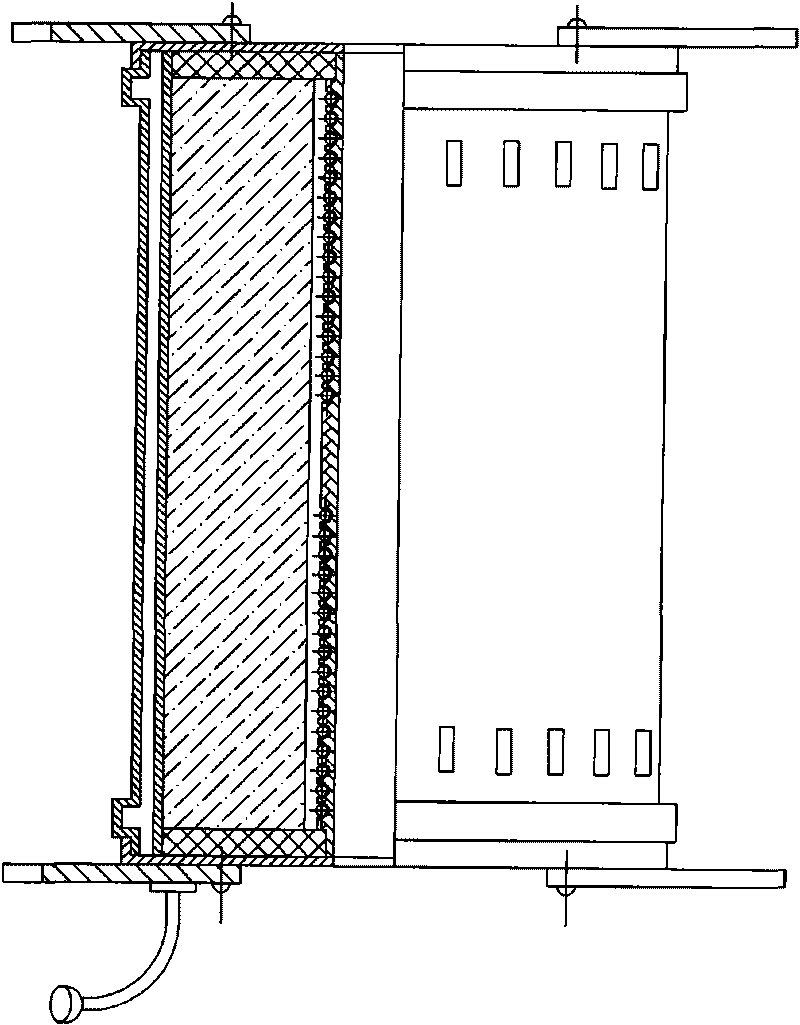

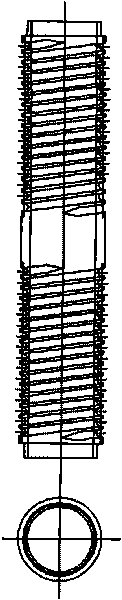

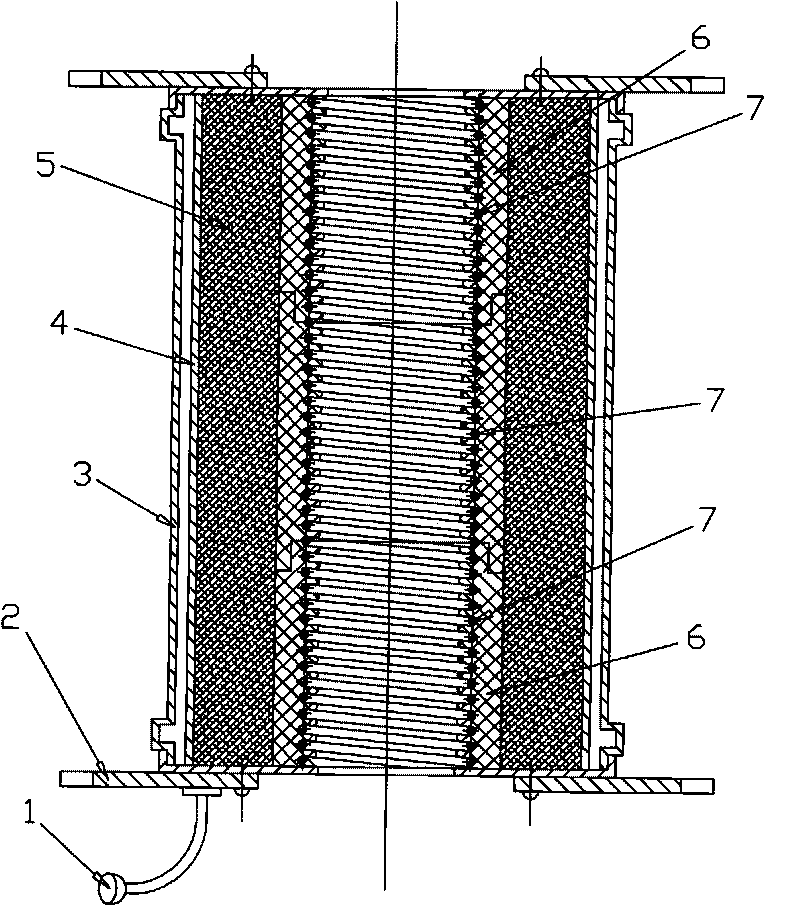

[0016] See attached Figure 3-7 As shown, the creep and durability test heating furnace is an open-flame furnace with a "tubular" structure, including an operating handle 1 and a fixing part 2. The furnace lining is composed of a heat-resistant layer 6 and an insulating layer 5. The furnace shell adopts a double-layer furnace The shell structure is composed of an outer furnace shell 3 and an inner furnace shell 4 . The overall dimension of the heating furnace is φ370×500mm, and the insulation layer 5 is made of aluminum silicate fiber cotton. The heat-resistant layer 6 at the core is a tubular structure, divided into upper, middle and lower layers. The heating adopts three sets of furnace wires 7 to control the temperature. On the inner wall of each layer of heat-resistant layer 6, furnaces are evenly arranged in a spiral shape. Wire 7 and furnace wire 7 use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com