Unsteady-state measuring device and method of heat conduction performance of multi-phase porous material

A porous material and measuring device technology, applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of test result distortion, long test time, influence, etc., and achieve the effect of avoiding contact thermal resistance and overcoming thermal convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

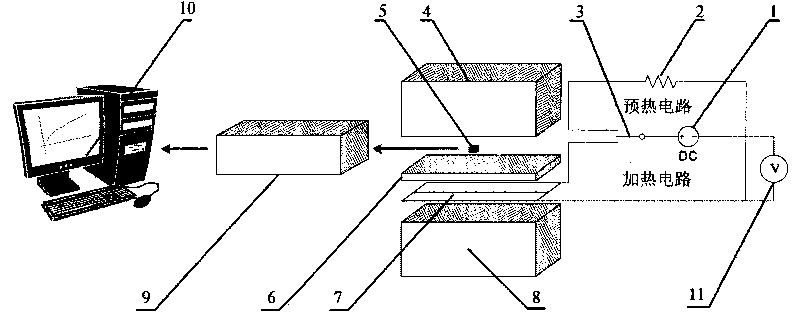

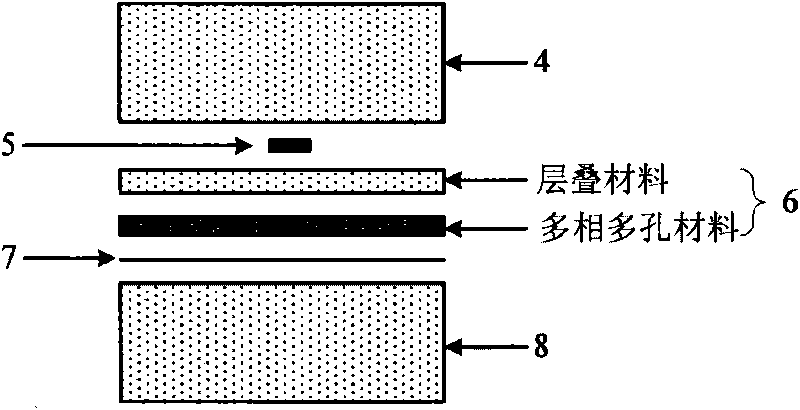

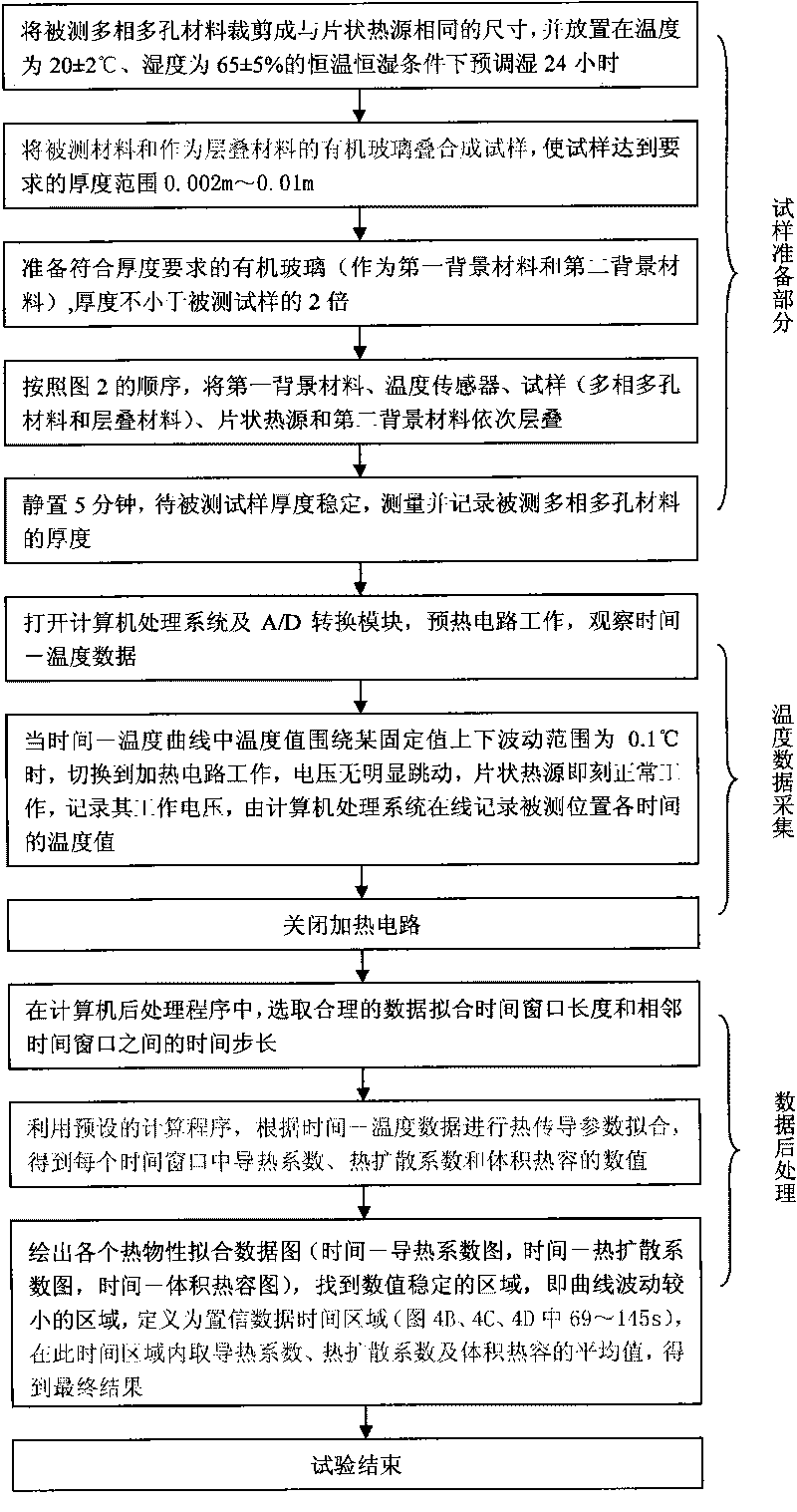

[0033] Such as figure 1 Shown is a schematic diagram of an unsteady-state measurement device for the thermal conductivity of a multiphase porous material provided by the present invention. An extremely thin metal flexible electric heating film (0.1×0.1×0.0002m in size) is selected as the sheet heat source 7, which can release a constant heat flux to the tested material. Select plexiglass (thermal conductivity 0.187W / mk, thermal diffusivity 9.00×10 -8 m 2 / s, volumetric heat capacity 2.08×10 6 J / m 3 k) As laminated materials (thickness range of laminated material and porous material is 0.002m-0.01m), first background material 4 and second background material 8 (thickness is 0.1m). Select a PT100 platinum resistor as the temperature sensor 5 and place it in the central groove of the first background material 4. The size of the groove should be the same as that of the platinum resistor (fix the platinum resistor with thermal silica gel), to ensure that it is compatible with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com