Electric spindle arranging structure easy to replace motor and using method thereof

An electric spindle and easy-to-replace technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of inconvenient disassembly and replacement of the spindle motor, cumbersome operation, and damage to the bearing combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

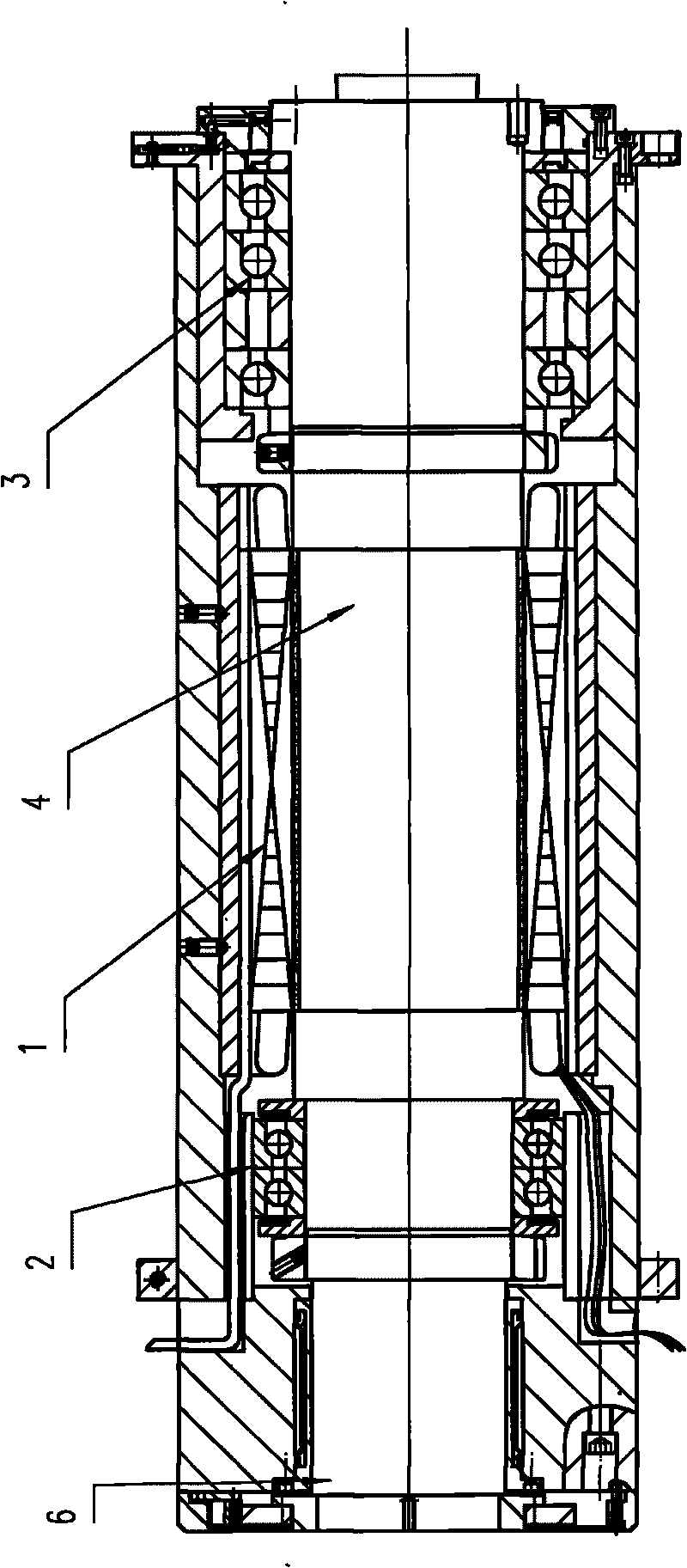

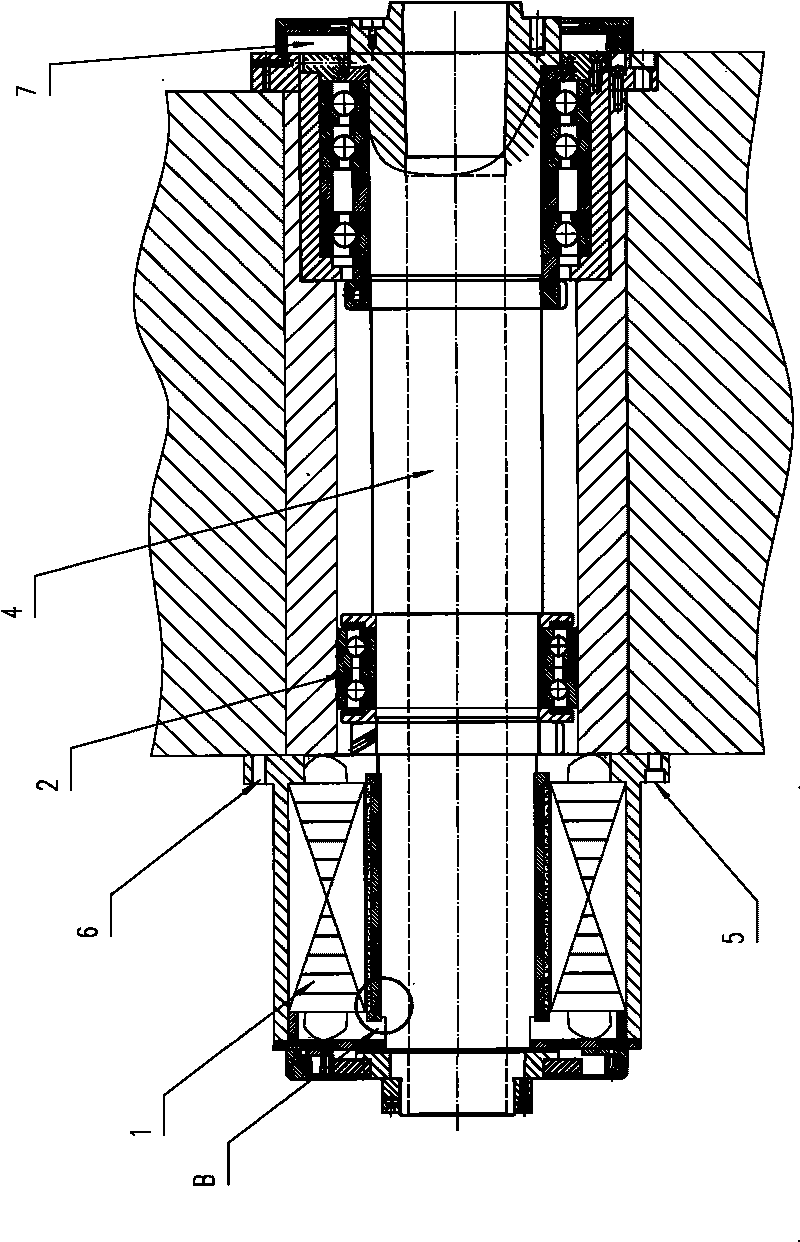

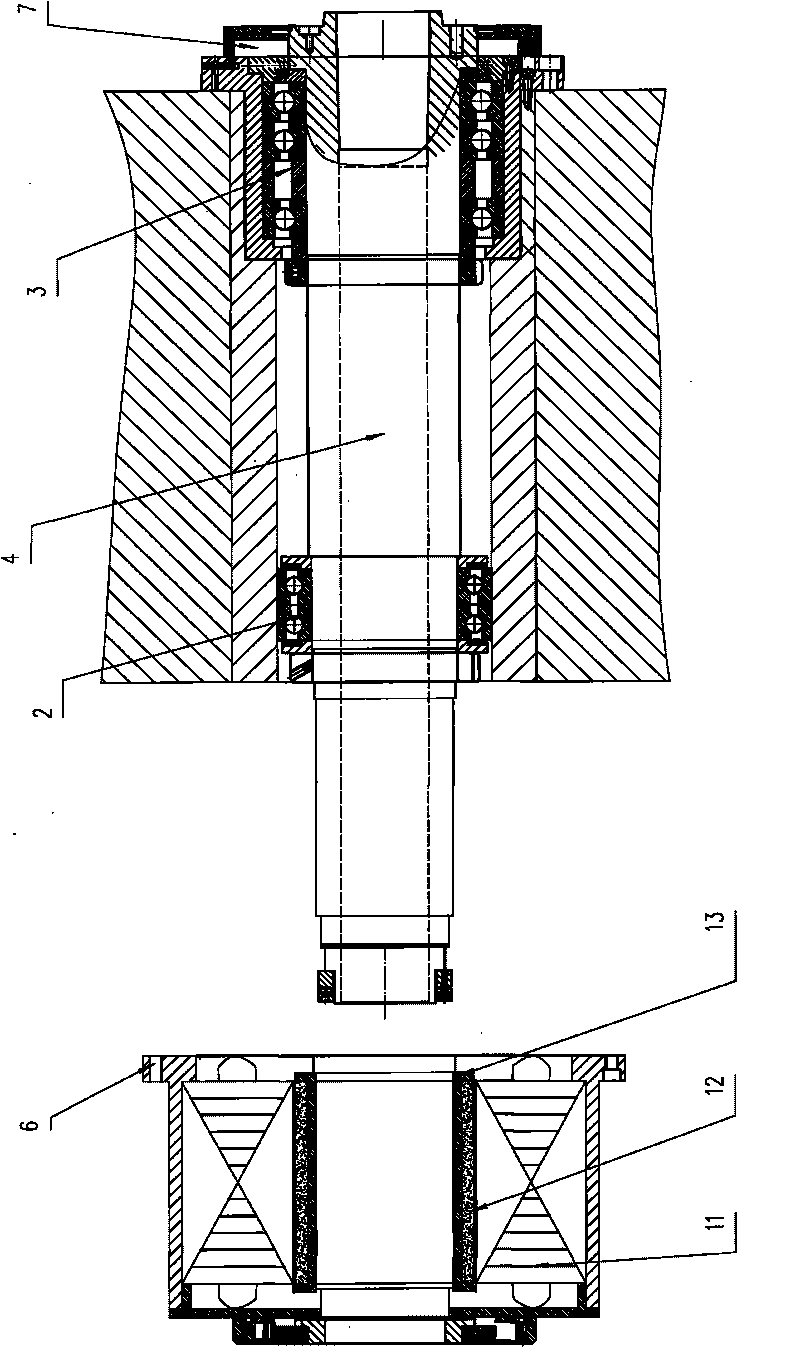

[0021] The basic structure of the workpiece electric spindle for a horizontal turning-milling compound machining center with a motor easily replaceable structure designed by the present invention includes: a replaceable low-speed high-torque motor and its components / a replaceable high-speed high-power motor and its components 1, a spindle The rear end bearing combination 2, the main shaft front end bearing combination component 3 and the main shaft mandrel 4 are composed of four major parts (such as figure 2 with 3 shown). In the figure, the main shaft motor assembly 1 is fixed on the rear side of the rear end bearing assembly 2, so that the rear end bearing assembly 2 and the front end bearing assembly 3 are located on the same side to assist the spindle 4 to rotate.

[0022] In addition, if image 3 The structure of the left spindle motor assembly 1 includes a stator 11 , a rotor 12 socketed on the inner diameter of the stator 11 , and a rotor bushing 13 socketed on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com