Press for high-speed pressing of powder metallurgy on basis of mechanical spring energy storage

A mechanical spring and high-speed pressing technology, which is applied in the field of powder metallurgy high-speed pressing presses based on mechanical spring energy storage, can solve the problems of expensive and complex equipment technology, and achieve the effects of small quantity, expanded application range, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

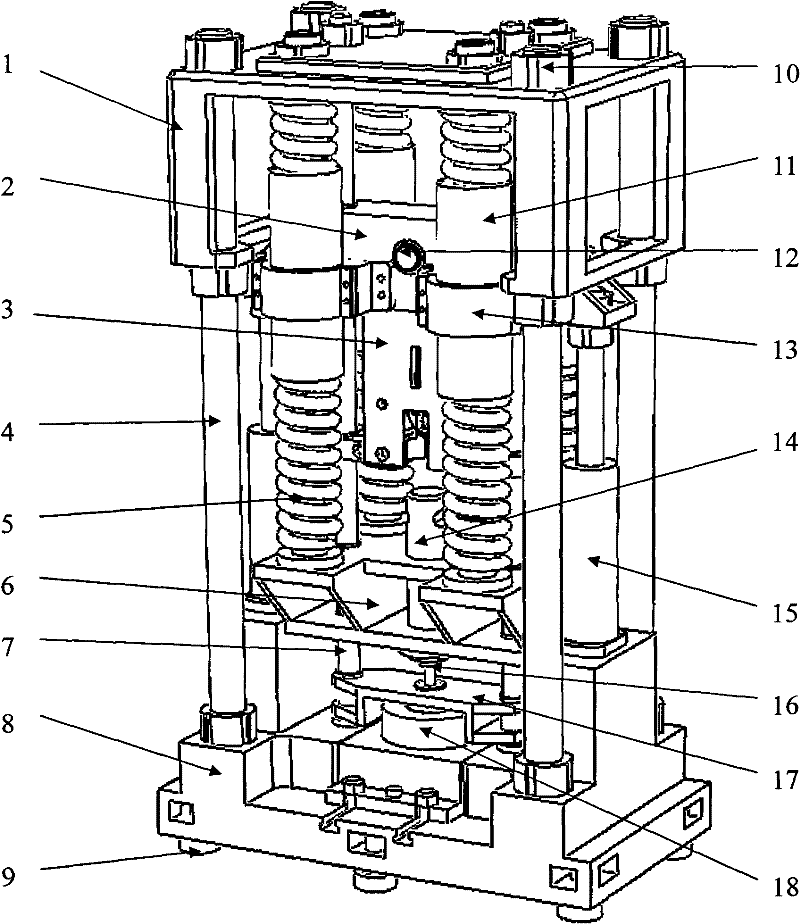

Embodiment Construction

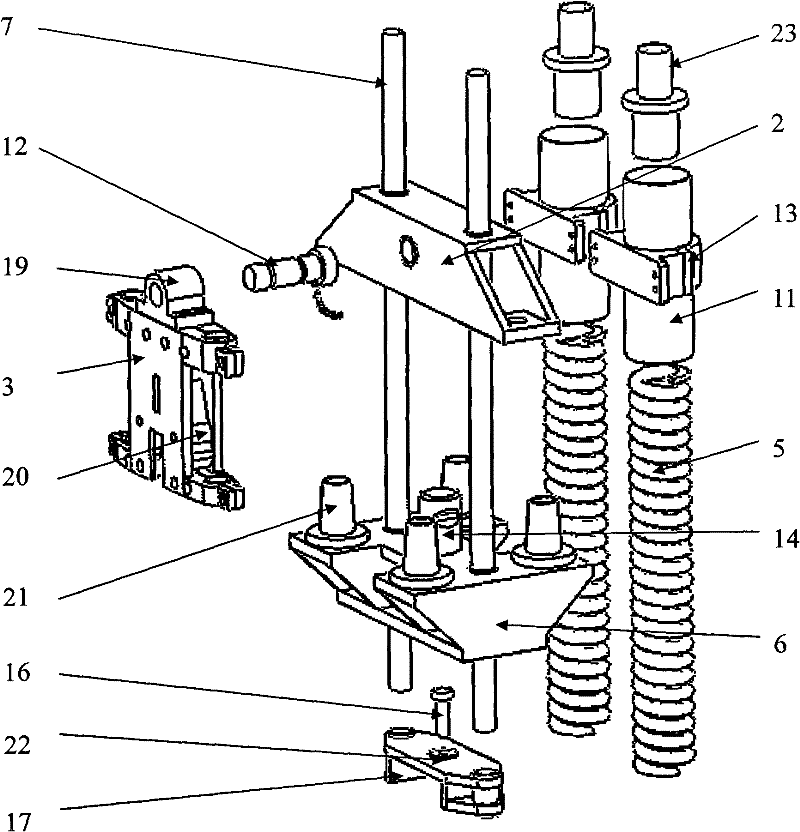

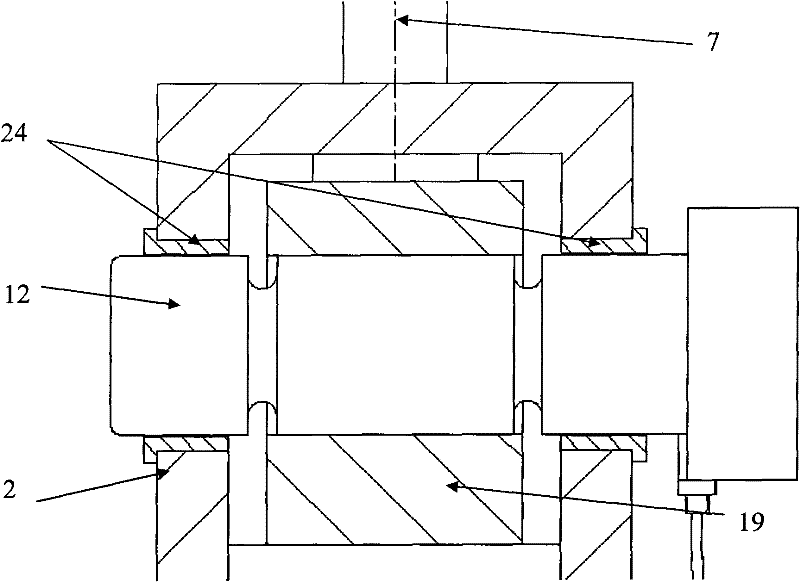

[0031] The weight lifting mechanism consists of a lifting member frame 2 with a through hole and a sensor sleeve 24 embedded in the through hole, four spring sleeves 11 and spring sleeve fasteners 13 arranged symmetrically, symmetrical and parallel to the axis of the moving direction. Arranged hydraulic piston cylinder 15; their connection relationship is as follows: the spring sleeve 11 is fixed on the lifting frame frame 2 through the spring sleeve fastener 13, and the piston rod of the hydraulic piston cylinder 15 and the two sides of the lifting piece frame 2 are arranged symmetrically. The ends are fixed by threads; the lifter frame 2 is welded by two front and rear parallel rectangular steel plates and ribs, and the middle space can accommodate the lug 19 of the hammer handle lock release mechanism. The sensor sleeve 24 is custom made to the specifications and dimensions of the pivot pin sensor 12 .

[0032] The hammer handle lock release mechanism is composed of a lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com