Motor directly driven electro-tricycle rear axle

A technology for electric tricycles and rear axles, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of heavy weight, increased friction, increased power loss, etc., and achieve simple structure, stable driving, and elimination of energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

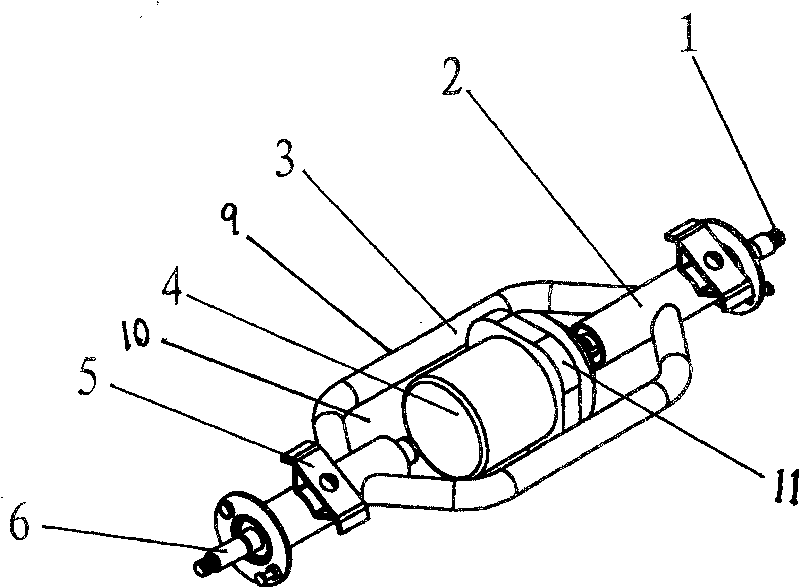

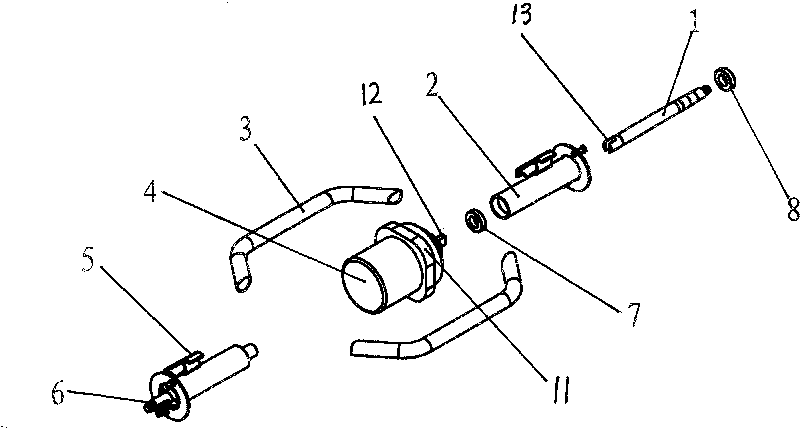

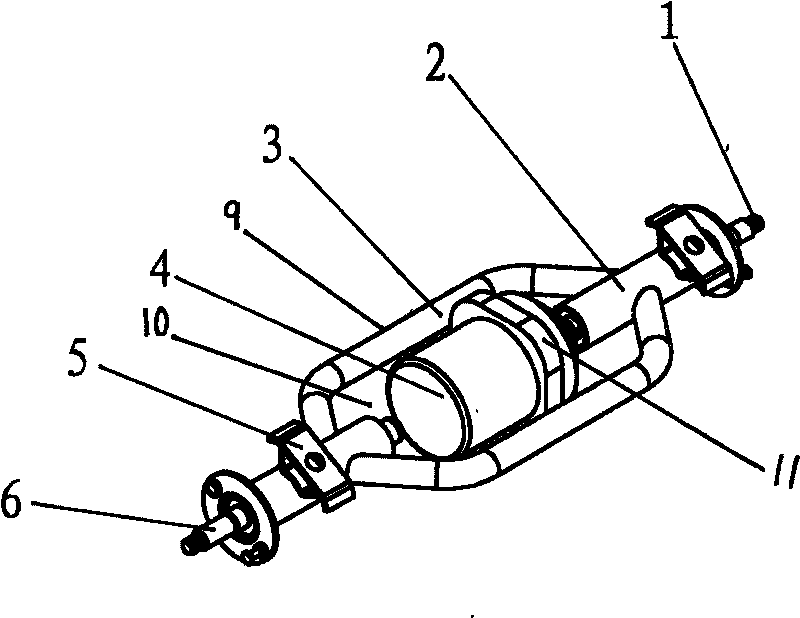

[0010] Depend on Figure 1-2 Represented is an embodiment of the present invention, and it comprises rear axle frame 9, and rear axle frame 9 is made up of two support pipes 3 connecting two axle sleeve pipes 2, forms window 10 apart from between two support pipes 3, A drive shaft 1 is housed on one shaft sleeve 2, a driven shaft 6 is housed on the other shaft sleeve 2, two left and right rear axle positioning plates 5 are arranged on the rear axle frame 9, and in the window 10, two support pipes 3. A motor mount 11 is made on the top, and a motor 4 is installed on the motor mount 11. The shaft of the motor 4 directly cooperates with the groove at one end of the drive shaft 1 through the tenon 12 at the end and is connected to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com