Steering engine swing mechanism with face gear transmission

A technology of swing mechanism and transmission mechanism, which is applied in the direction of rudder steering and steering, which can solve the problems of complex design, manufacture and assembly, complex support structure, unbalanced load, etc., and achieve simplified support, reduced structural weight, and axial manufacturing error insensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

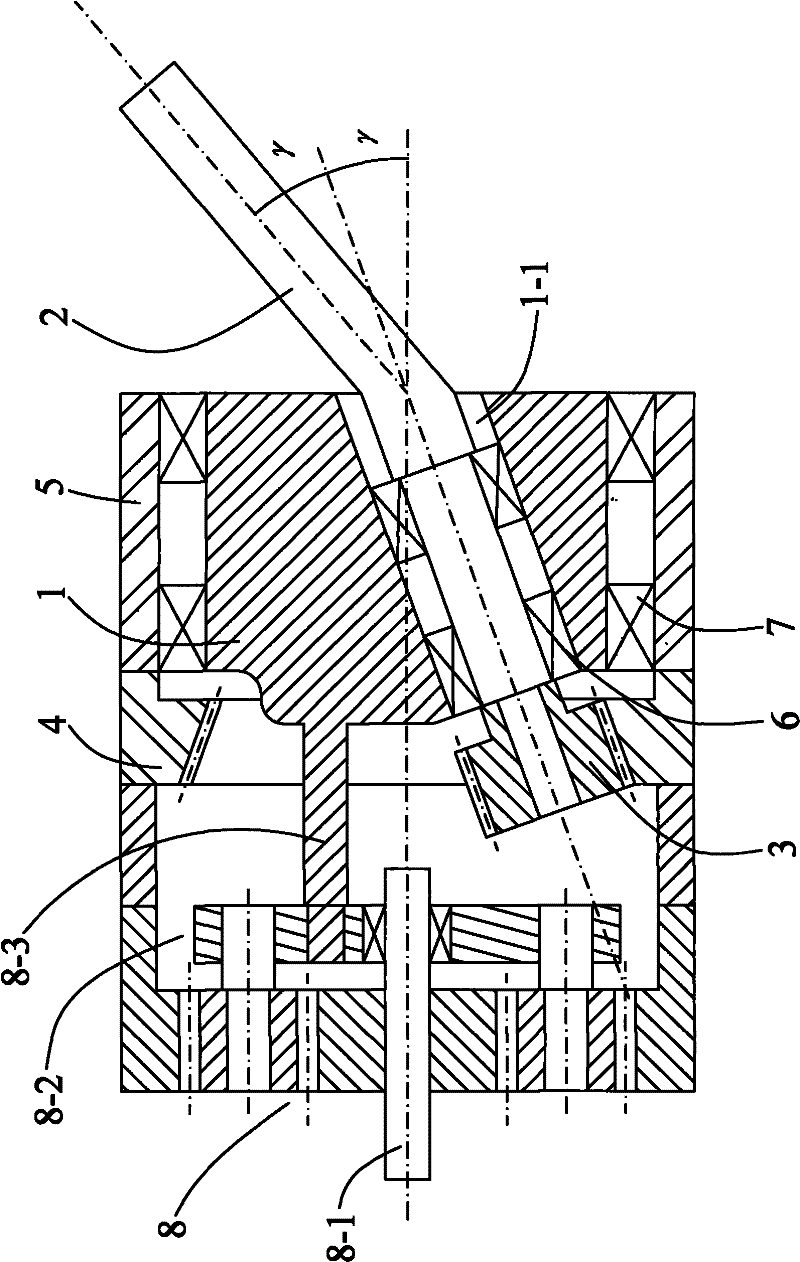

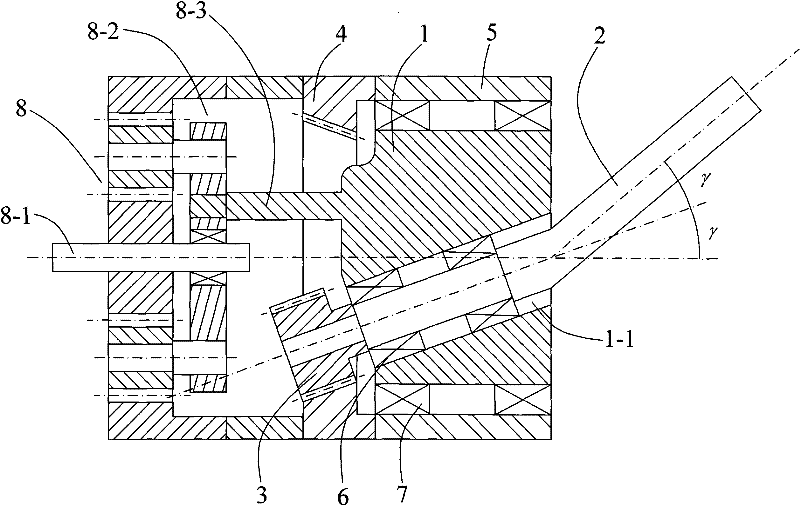

[0020] Such as figure 1 As shown, the steering gear swing mechanism with face gear transmission in this embodiment includes a driving part 1, and an oblique penetration hole 1-1 is set on the driving component 1, and in the oblique penetration hole 1-1 An eccentric lever 2 is inserted in the 1. The part of the eccentric lever 2 is located in the oblique penetration hole 1 - 1 , and the other part of the eccentric lever 2 is located outside the driving part 1 . The input end of the eccentric lever 2 is fixedly connected with a straight involute spur gear 3 . The spur gear 3 and the face gear 4 mesh with each other. A sleeve 5 is placed outside the driving part 1 , and the face gear 4 is fixedly connected to one end surface of the sleeve 5 .

[0021] An eccentric lever support bearing 6 is arranged between the eccentric lever 2 and the drive part 1 ; a drive part support bearing 7 is arranged between the drive part 1 and the sleeve 5 .

[0022] The power input mechanism 8 in...

Embodiment 2

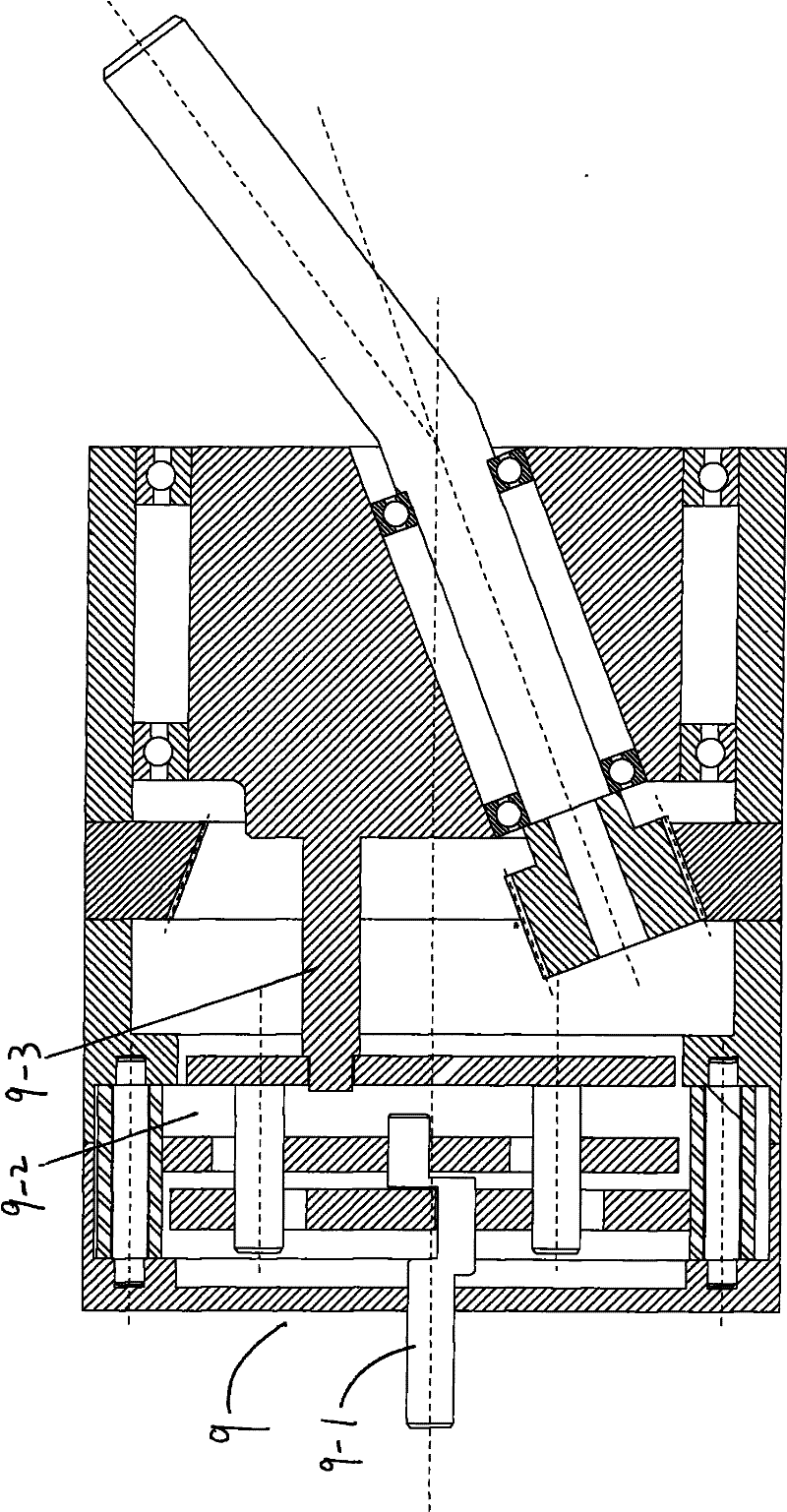

[0025] The steering gear swing mechanism with face gear transmission in this embodiment is roughly the same as the steering gear swing mechanism with face gear drive in Embodiment 1, the difference lies in the power input mechanism.

[0026] The power input mechanism 9 in this embodiment includes a power input shaft 9-1, a cycloidal pinwheel reduction transmission mechanism 9-2 and a drive component connecting shaft 9-3. The power input shaft 9-1 is connected with the cycloidal pinwheel reduction transmission mechanism 9-2, and the driving component connecting shaft 9-3 is connected with the cycloidal pinwheel reduction transmission mechanism 9-2 and the driving component 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com