Internal loop piston pump

A technology of piston pump and internal circulation, applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of easy generation of dead volume, inconvenient processing of tooth profile lines, etc., to ensure processing accuracy and smoothness , improve the processing accuracy and smoothness, and prevent the effect of dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

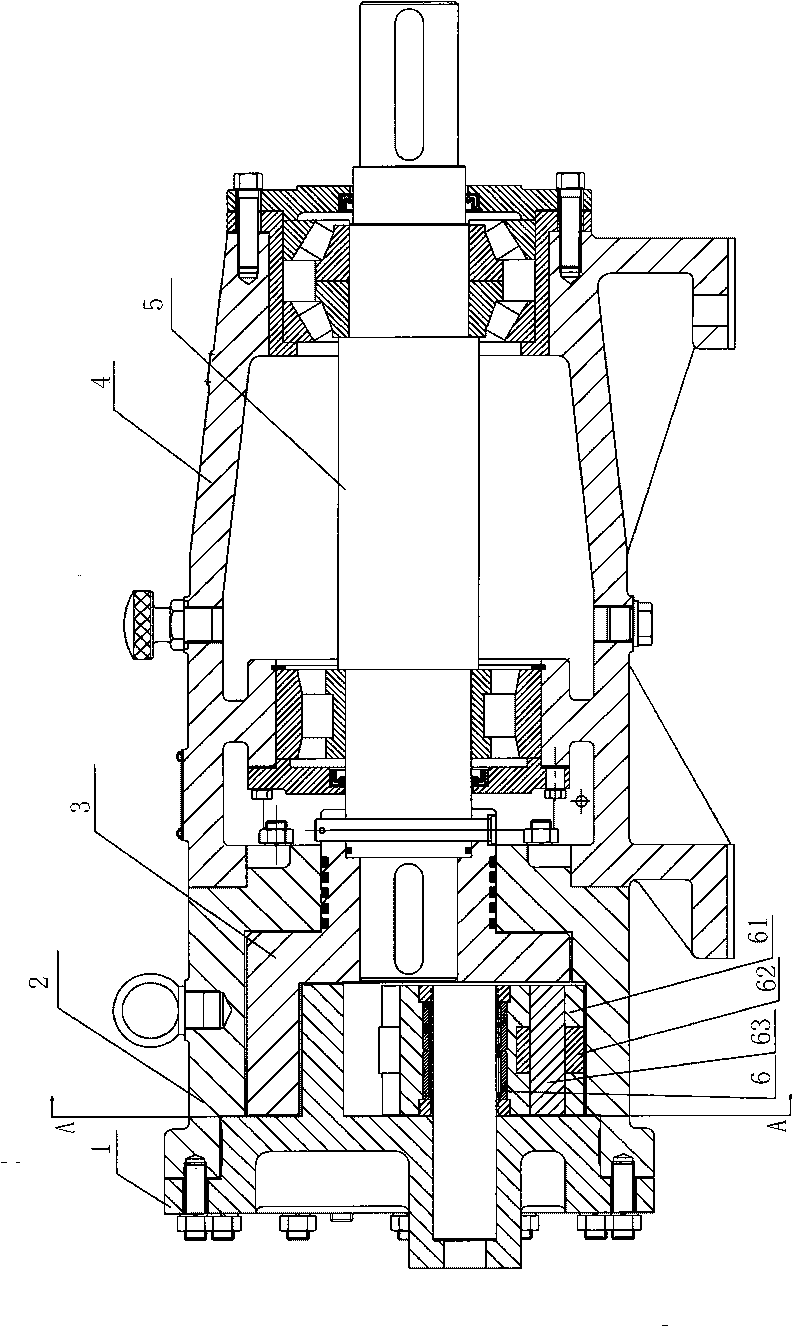

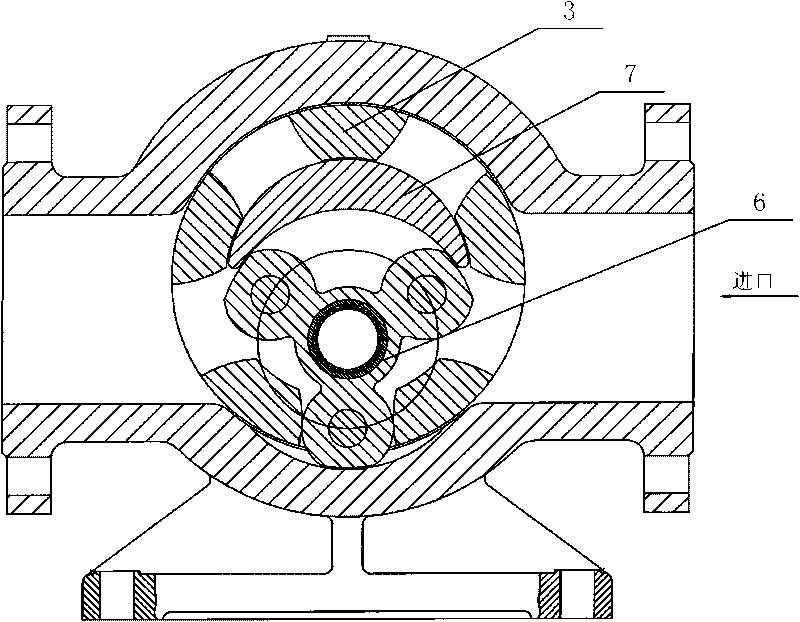

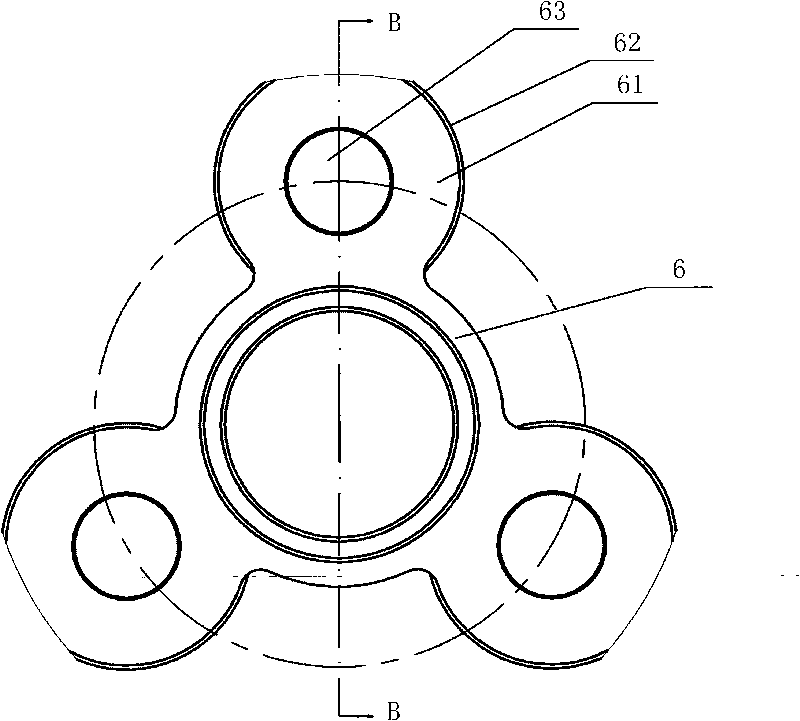

[0016] refer to Figure 1-4 , an inner circulation piston pump, including a pump cover 1, a pump body 2, an outer rotor 3, a bracket 4, a pump shaft 5, an inner rotor 6, and a crescent-shaped partition 7, and the body of the inner rotor 6 is connected with several Uniformly distributed rotor body 61, the outer rotor 3 meshes with the inner rotor 6, the crescent-shaped partition 7 separates the liquid suction area and the liquid discharge area, and the rotor body 61 is provided with a rotor tooth 62, the rotor tooth The tooth profile of 62 is larger than that of the rotor body 61 , and the inner rotor 6 contacts and meshes with the outer rotor 3 through the rotor teeth 62 .

[0017] The rotor teeth 62 are fixed on the rotor body 61 through connecting posts 63 .

[0018] Driven by the motor, the pump shaft 5 drives the outer rotor 3 to rotate, and at the same time, the outer rotor 3 and the inner rotor 6 perform internal meshing movement to work. The crescent-shaped partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com