Overhead wire icing on-line monitoring device based on machine vision

An overhead line and machine vision technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not providing ice thickness, density, lack of science, and lack of image analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

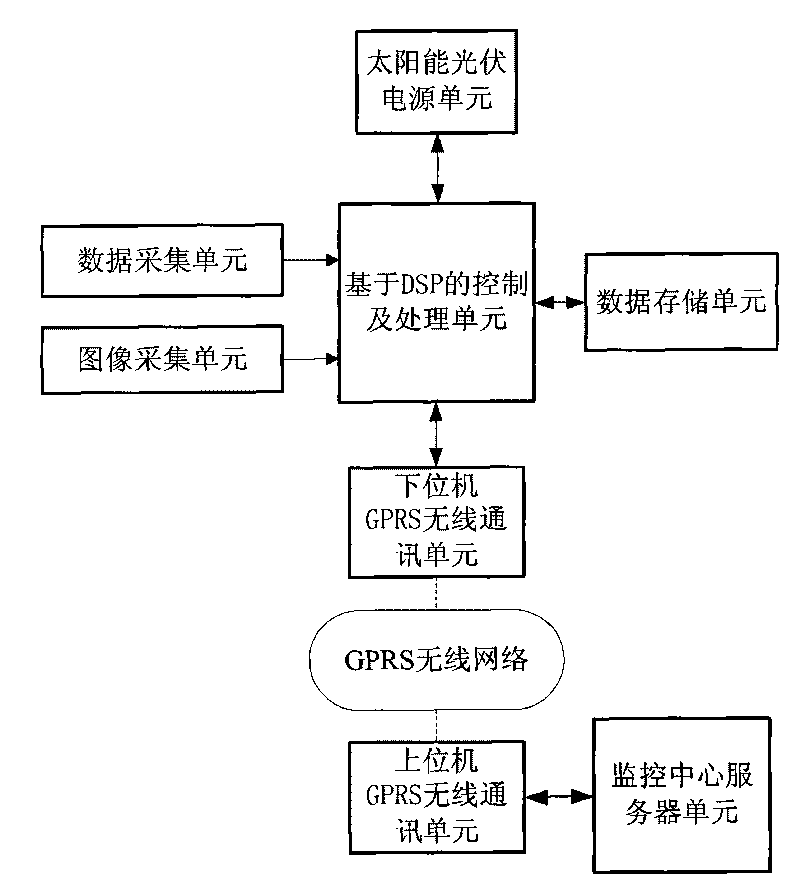

[0040] The hardware structure of an overhead line icing online monitoring device based on machine vision technology can be divided into two parts: the hardware of the lower computer and the hardware of the upper computer. The schematic diagram of the hardware part is as follows: figure 1 shown. The lower computer hardware is composed of DSP-based control and processing unit, image acquisition unit, data acquisition unit, data storage unit, GPRS wireless communication unit and solar photovoltaic power supply unit. The image acquisition unit, data acquisition unit, data storage unit, GPRS wireless communication unit and solar photovoltaic power supply unit are respectively connected with the control and processing unit based on DSP. The host computer hardware is composed of the monitoring center server unit and the GPRS wireless communication unit, which are connected by serial ports.

[0041] The DSP-based control and processing unit is composed of TMS320DM642DSP chip, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com